Transporting apparatus and transporting method for container-handling installation, and container-handling installation with such a transporting apparatus

A processing device and conveying device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of high purchase and maintenance costs, and achieve the effects of low cost, extended inspection time, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

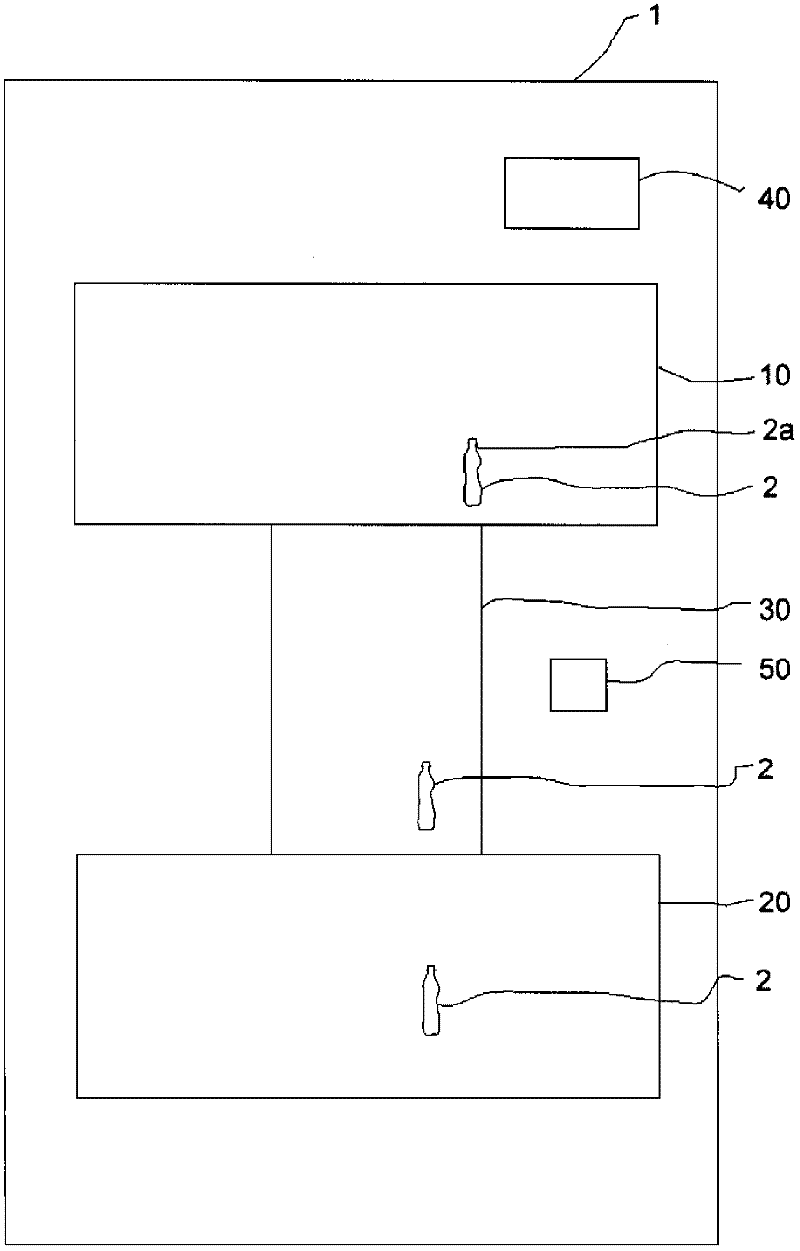

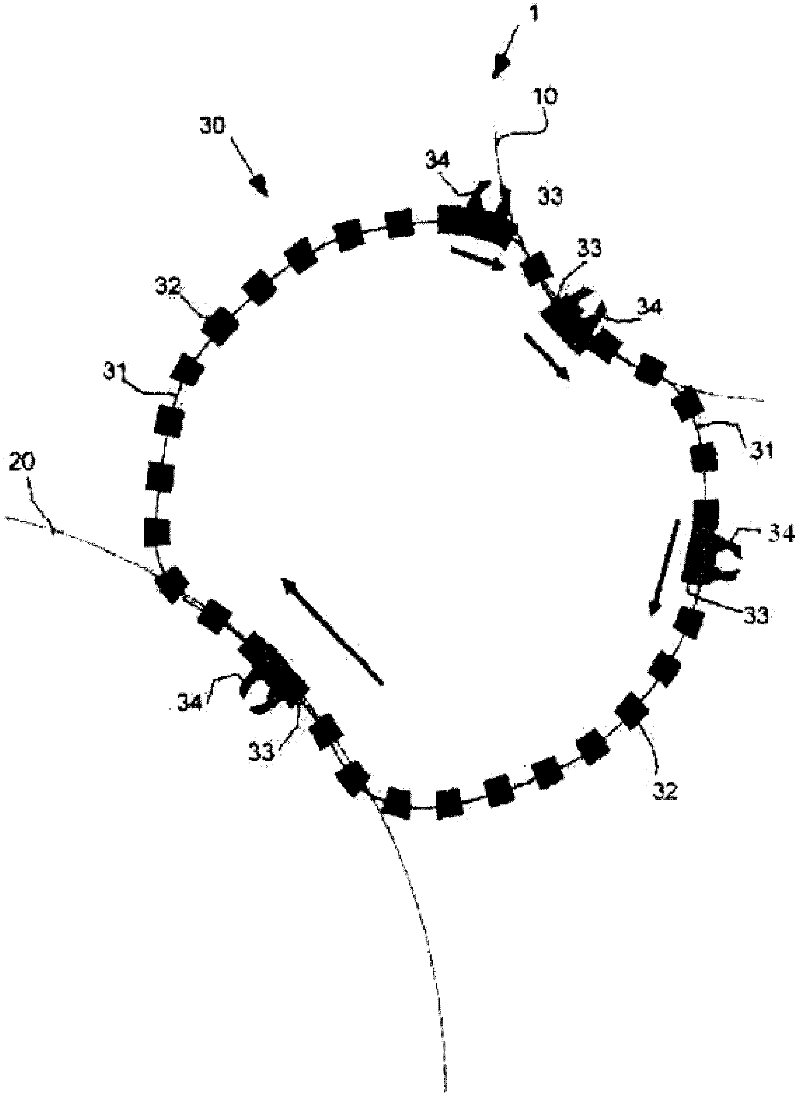

[0086] figure 1 A container handling device 1 for handling containers 2 with a neck ring 2a. The container processing plant 1 comprises at least one first processing device 10 , a second processing device 20 , a transfer device 30 arranged between the first and second processing device 10 , 20 , a control device 40 and a detection device 50 .

[0087] The first processing device 10 is used for processing the containers 2 and may for example be a heating device for heating plastic parisons to a temperature suitable for a scalable blow molding process. The second treatment device 20 is also used to process the container 2 and may be, for example, a telescopic blow molding device which exposes the container 2 heated by the heating device, i.e. the first treatment device 10, for telescopic blow molding. Plastic process. This means that the treatment of the containers 2 that can be performed by the first and second treatment means 10 , 20 is a predetermined type of treatment.

...

no. 2 example

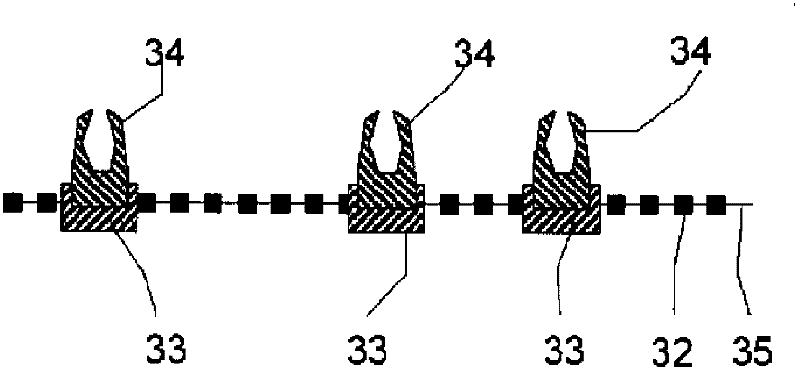

[0105] The transfer device 30 according to the second embodiment has Figure 1 to Figure 4 The same parts of the delivery device 30 are shown. Therefore, identical and equivalent parts in both embodiments are provided with the same reference numerals.

[0106] The difference between the examples of the first and second embodiment is that, in the example of the present embodiment, the conveying element 33 along the conveying track 31 is driven not only electromechanically by means of the electromagnet 32 . Therefore, only this distinction will be described below.

[0107] Instead of driving the conveying element 33 along the conveying track 31 by means of an electromagnet 32, it is also possible to use, for example, Figure 5 The conveyor belt 36 shown drives the conveyor elements 33 along a straight section of the conveyor track 31 . This is particularly advantageous in the case of longer straight sections along which the conveying element 33 moves with a constant velocit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com