Folding process for ship bow and stern block construction

A technology for general sections and hulls, which is applied in the field of closing technology for the construction of the bow and stern sections of the hull, can solve the problems of increased construction cost and period, long time consumption, and large investment, and achieve shortened construction period, reduced construction cost, and smooth construction process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments. In the description of the present invention, unless otherwise specified, "plurality" means two or more.

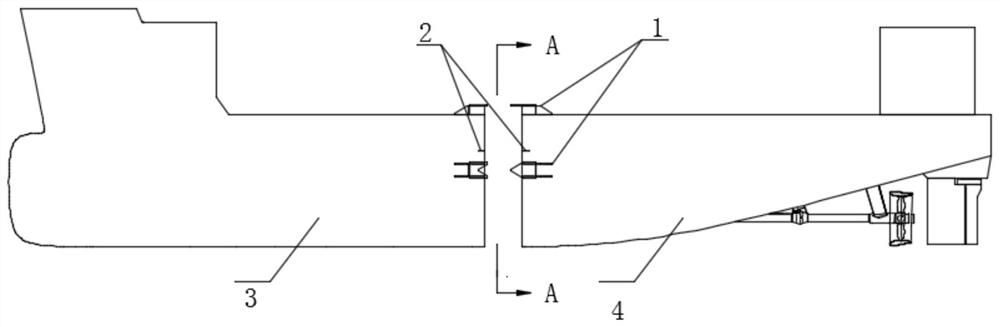

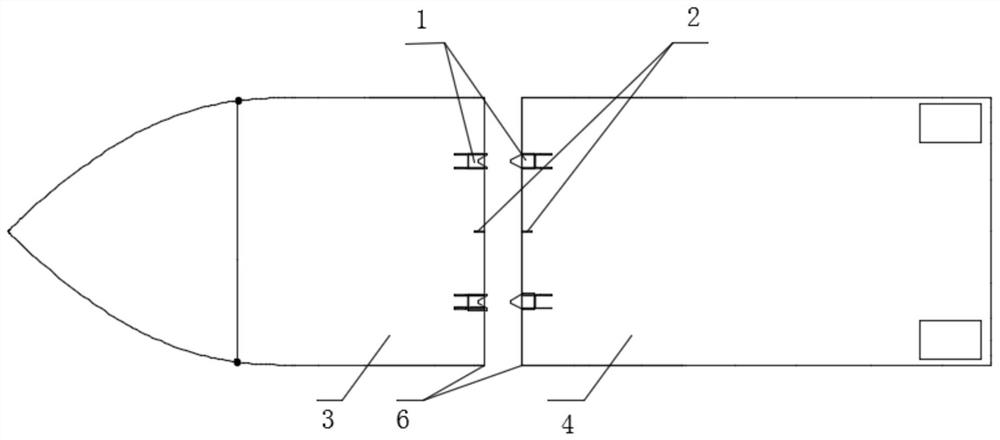

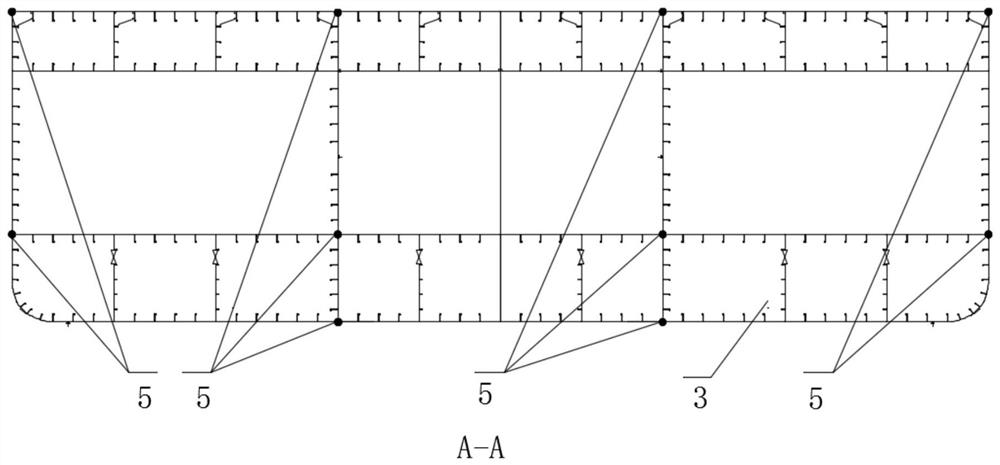

[0037] see Figure 1-5 , the present invention provides a closing process for the construction of the bow and stern general section of the hull, comprising the following steps:

[0038] 1) The hull is divided into the bow section 3 and the stern section 4 and closed on the berth; compared with the overall closing of the ship, the working surface can be doubled theoretically and the closing period of the berth can be shortened by half;

[0039] 2) After the closure is completed, draw the positioning line 2 on the main deck surface and the closing openings of the bow general section 3 and the stern general section 4 as required, and install the guiding and positioning tool 1;

[0040] 3), use the instrument to measure the ports of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com