Method for assembling ship slot-shaped bulkhead

An installation method and groove type technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor safety, inconvenient construction, high cost, etc., and achieve the improvement of welding efficiency and welding quality, and difficult operation Effect of reduction and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

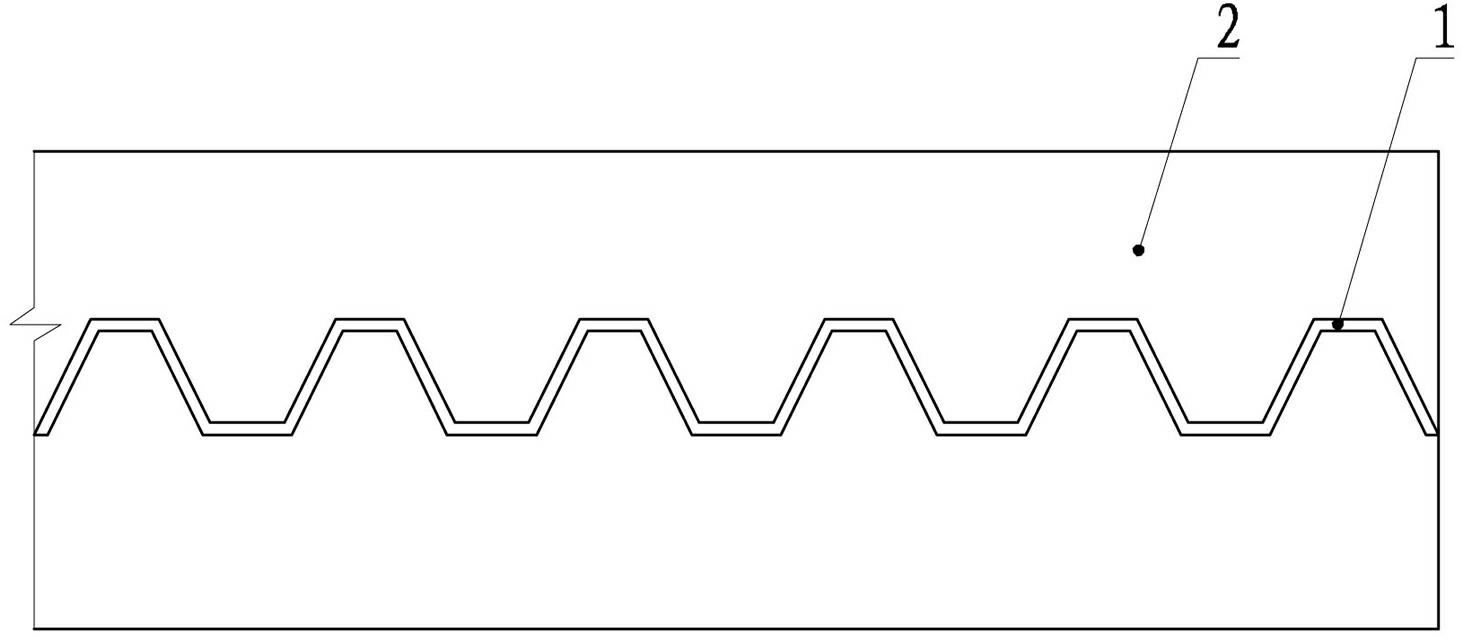

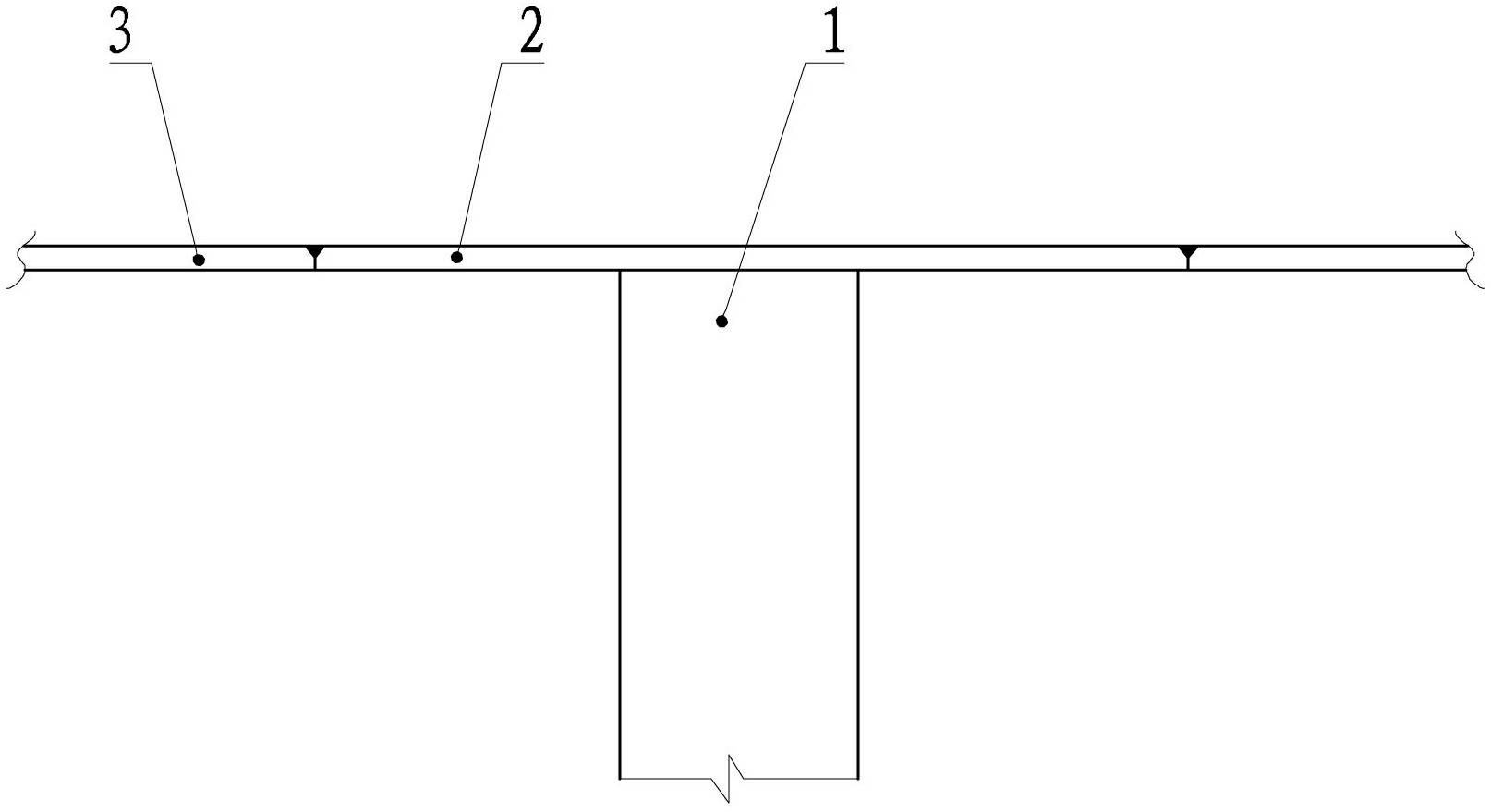

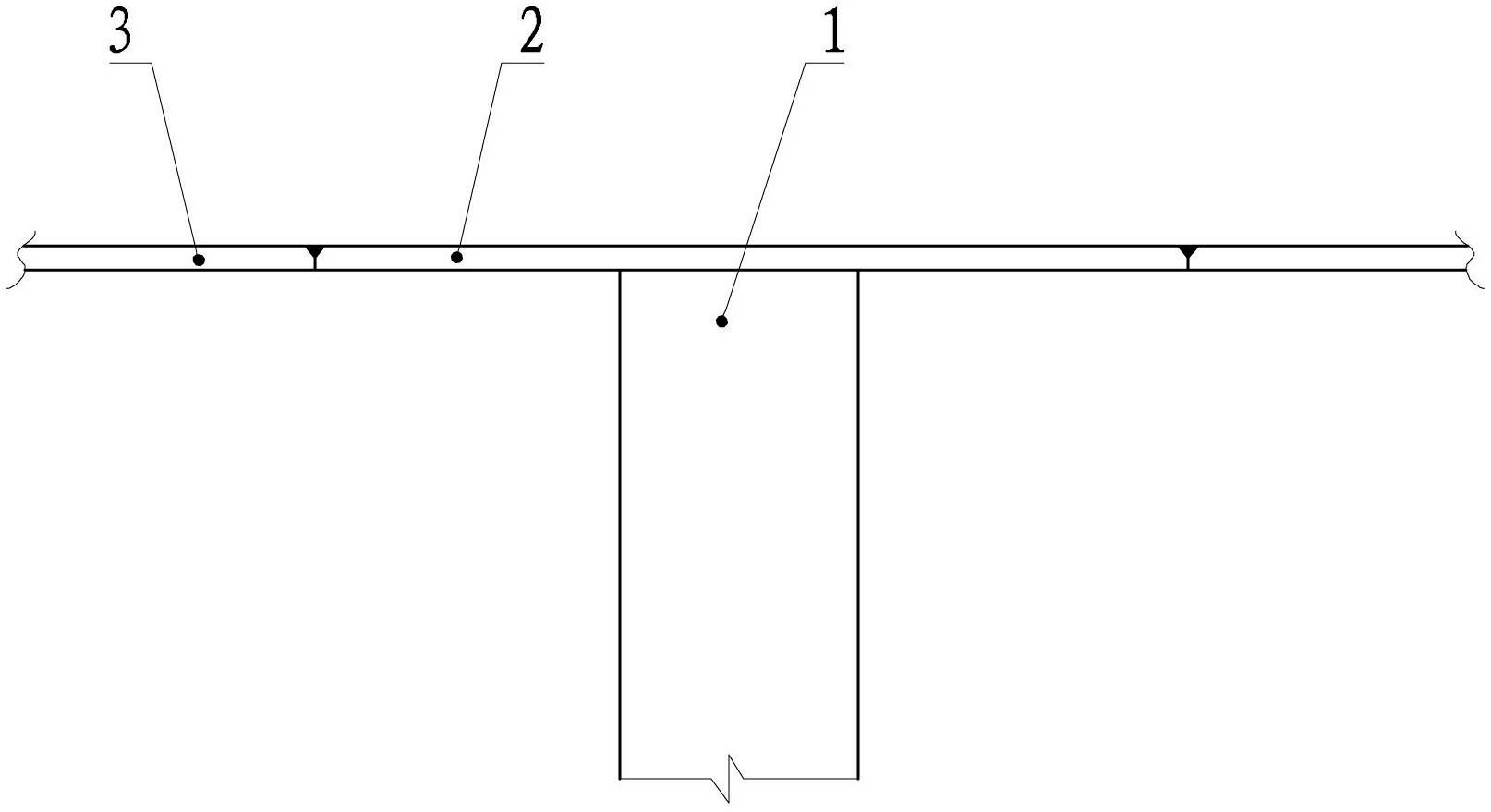

[0009] Example: A 16500DWT Class II product oil / chemical carrier, with longitudinal and transverse grooved bulkheads in the cargo hold. If according to the prior art scheme, after the grooved bulkhead and the lower deck are positioned, then the upper deck section is closed up, so there will be an overhead weld of more than 3000 meters. However, overhead welding is difficult in construction, poor in forming, inconvenient in construction, and long in cycle. Now the upper deck section is combined with the vertical and horizontal corrugated bulkhead section, that is, the middle longitudinal deck steel plate of the upper deck and the deck steel plate connected with the transverse corrugated bulkhead are separated from the upper deck section Connect part 2 for the deck. After the corrugated bulkhead 1 is formed, they are assembled and welded when the vertical and horizontal corrugated bulkheads are constructed in sections. At this time, the corrugated bulkheads carried out on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com