A self-sealing high-pressure valve

An automatic sealing and high-pressure valve technology, which is applied in shaft sealing, valve details, valve devices, etc., can solve the problems of high sealing cost, difficult sealing, poor consideration of its own structure and flow field characteristics, etc., so as to increase the degree of freedom and reduce the The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

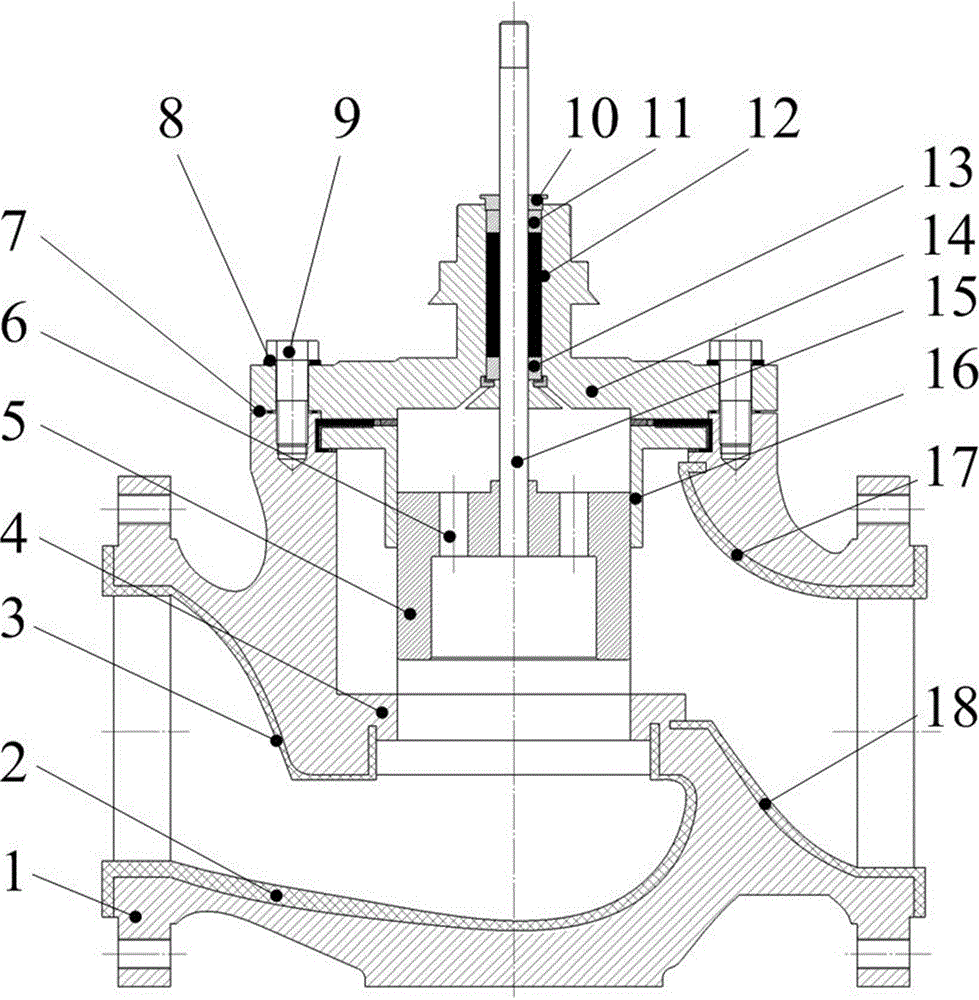

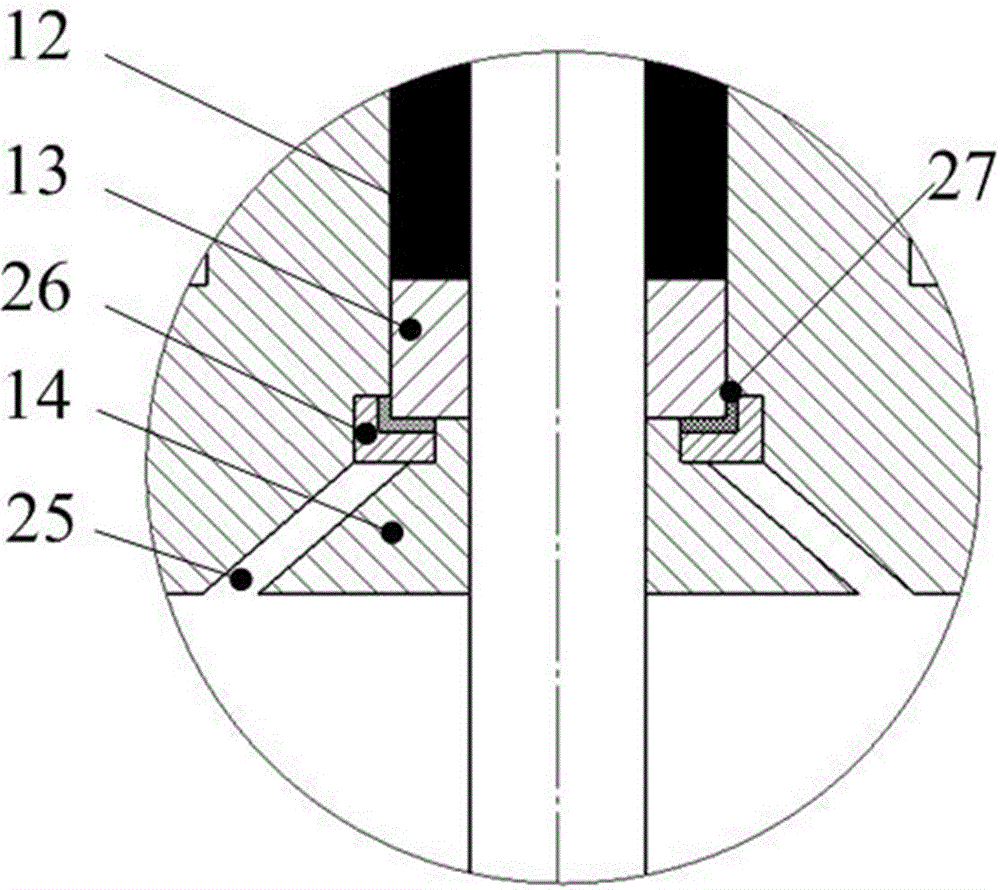

[0017] like figure 1 As shown, a self-sealing high-pressure valve of the present invention is mainly composed of a valve body 1 , a valve core 6 , a valve stem 15 and a valve cover 14 . A sealing ring 7 is installed between the valve cover 14 and the valve body 1, and is fixed by a gasket 8 and a screw 9. The spool 6 has a balance hole 6, the spool 6 is installed on the valve stem 15, the valve stem 15 is sealed by the packing 12, the upper end of the packing 12 is pressed by the packing gland 10 and the collar 11, and the lower end of the packing 12 is passed by the stuffing box ring 13 is compressed, and the stuffing box ring 13 is compressed by the valve core automatic sealing device.

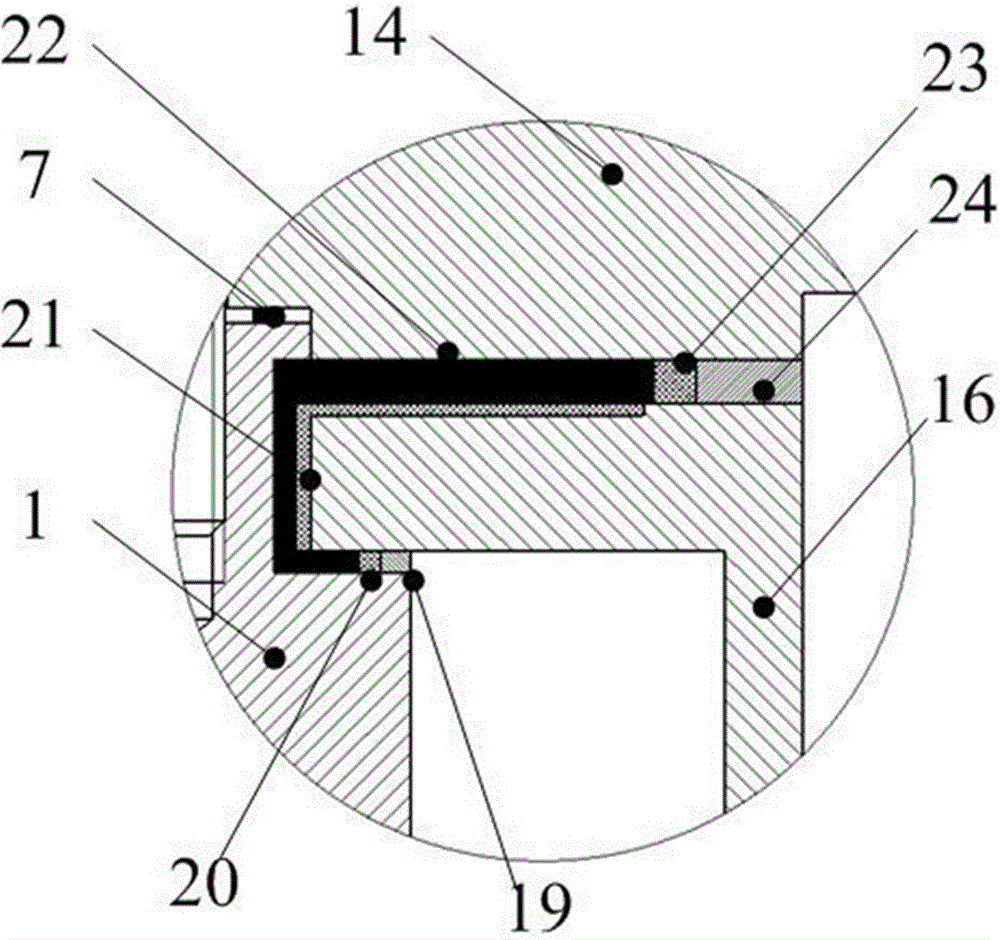

[0018] The upper end of the valve body 1 and the valve seat 4 are provided with grooves, and each groove is equipped with an automatic sealing device for the valve cover and an automatic sealing device for the valve interface. The inlet and outlet of the high-pressure valve are equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com