Method and device for dynamic and intelligent control of foamed concrete component proportional mixing

A foamed concrete, intelligent control technology, applied in control devices, mixing operation control devices, clay preparation devices, etc., can solve the problems of unstable proportion control, waste of dry material and liquid medicine, high labor intensity, etc., and achieve stable mixing ratio. , Reduce labor intensity and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

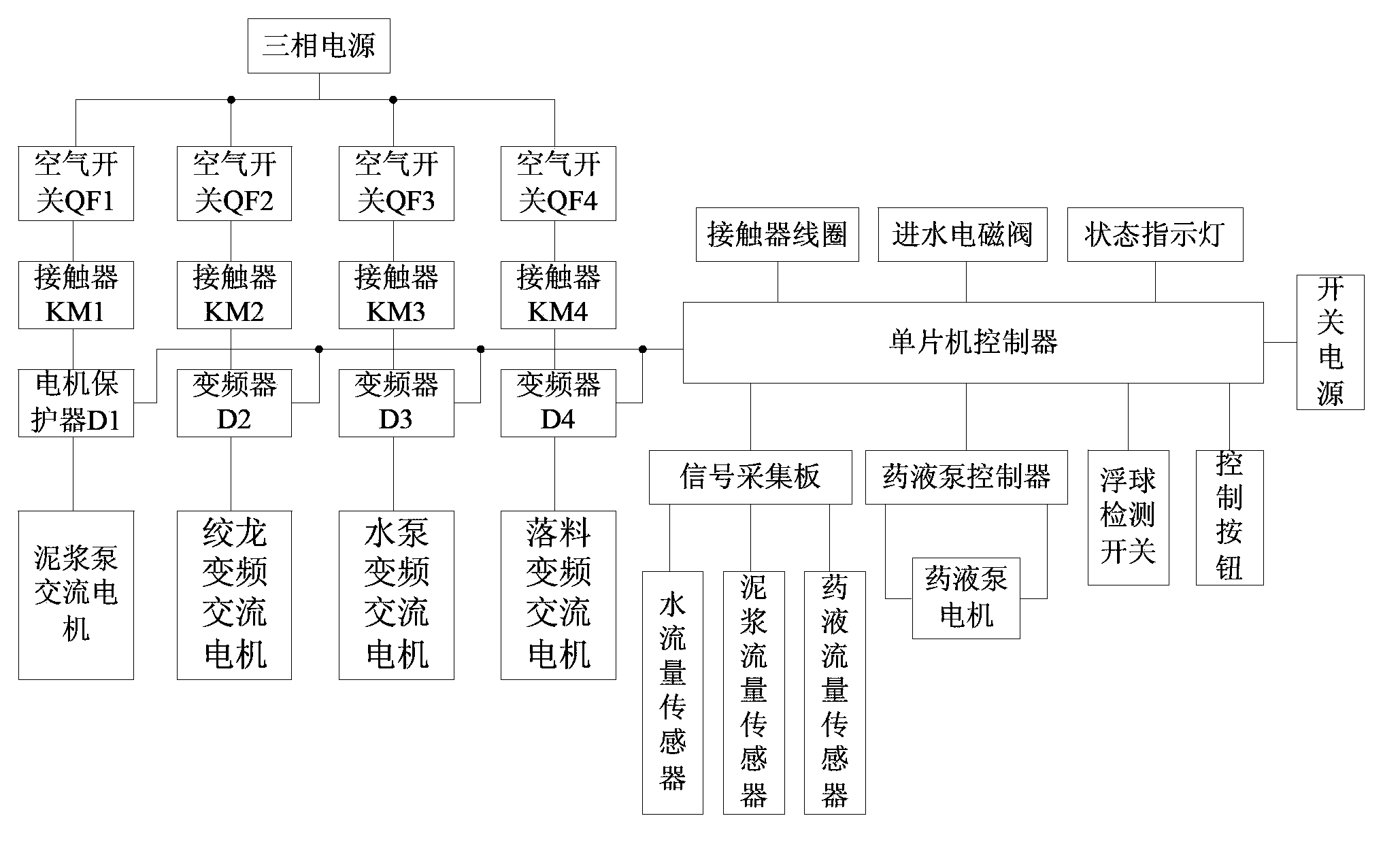

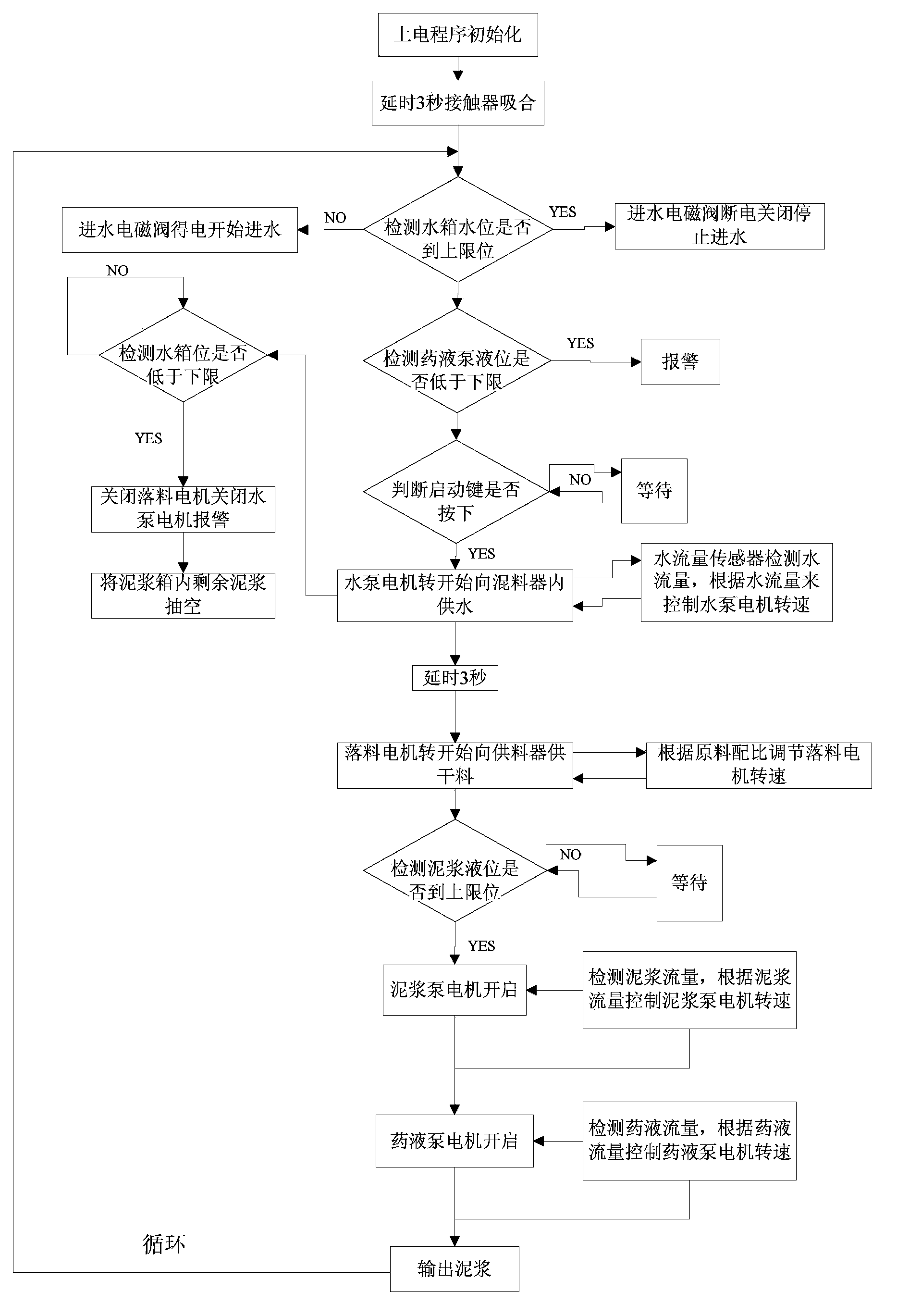

[0027] The water content of the mud is related to the ratio of dry material and water, and the foaming degree of concrete is related to the ratio of mud and liquid medicine. The ratio of these several materials can be controlled by a flow sensor, which can detect the flow of water, the flow of mud, and the flow of medicinal liquid. The amount of dry material, water, and liquid medicine can be controlled by the single-chip controller with RS485 communication to the inverter (or control board). Because the single-chip computer is used to control the programmability of its components, the digital adjustment of the single-chip computer is quite flexible, which is convenient for formula parameters. fix. This system uses STC5A60S2 dual-serial-port MCU (one serial port is used for man-machine interface communication, and the other serial port is used for RS485 communication with external devices such as inverters). The dry material can be controlled by the frequency converter to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com