Smoke distributing device for heat accumulating type burning industrial furnace, smoke distributing assembly with smoke distributing device and industrial furnace

An industrial furnace and regenerative technology, applied in the direction of furnace components, combustion equipment, furnaces, etc., can solve the problems of fan damage and high cost, and achieve the effect of reducing emissions and simplifying operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

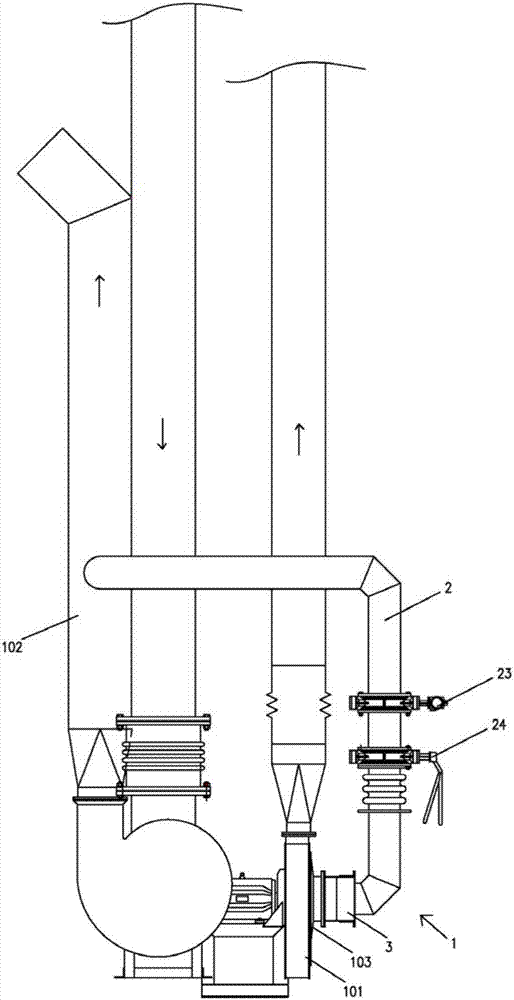

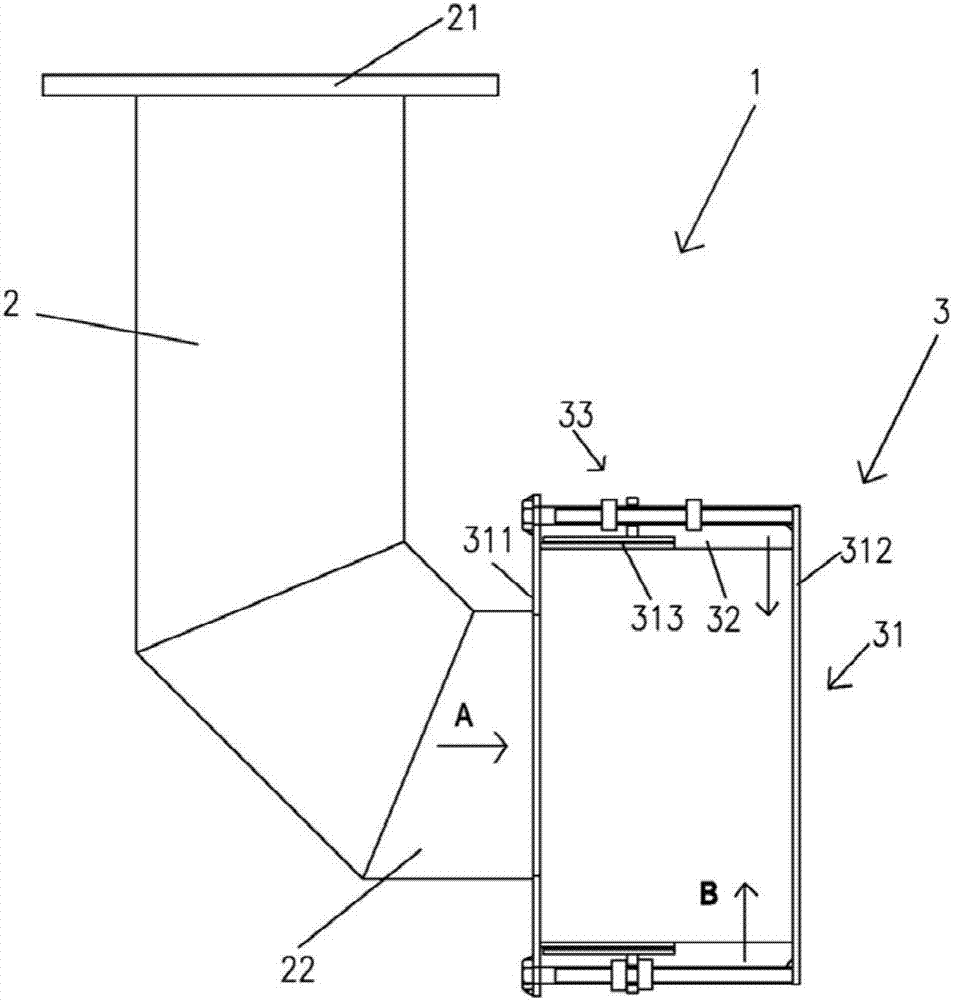

[0040] figure 2 4 shows the schematic structure of the smoke distributing device 3 according to the first embodiment of the present invention.

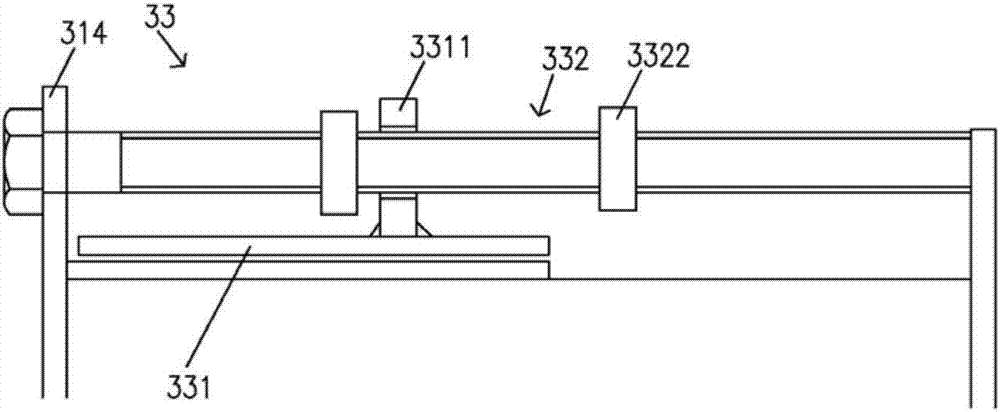

[0041] Such as figure 2 As shown, the smoke distribution device 3 includes a cylindrical body 31 , a plurality of air inlets 32 disposed on the cylindrical body 31 , and an adjusting device 33 for adjusting the intake area of the air inlets 32 .

[0042] The cylindrical body 31 includes a first end 311 for connecting with the flue gas return pipe 2 , a second end 312 for connecting to the fan inlet 103 and a side wall extending between the first end 311 and the second end 312 313.

[0043] The first end 311 is provided with an opening for connecting the outlet end 22 of the flue gas return pipe 2 , so as to introduce the flue gas discharged from the outlet end 22 into the cylindrical body 31 . The outlet port 22 is preferably disposed at the center of the first end 311 , that is, the opening is disposed at the center of the fir...

no. 2 example

[0056] Figure 5 The schematic structure of the smoke distributing device 1 according to the second embodiment of the present invention is shown. The second embodiment differs from the first embodiment only in that the outlet end 22 of the flue gas return pipe 2 extends from the first end 311 of the cylindrical body 31 of the smoke distribution device 3 through the interior of the cylindrical body 31 and reaches the cylinder. The second end 312 of the shaped body 31 is formed to form a mixing zone of smoke and air at the end face of the second end 312 (ie, the plane where the end is located). Other parts of this embodiment can be the same as the first embodiment. For brevity, only this difference is described here.

[0057] In this embodiment, the outlet end 22 of the flue gas return pipe 2 passes through the cylindrical body 31 of the smoke distribution device 3 , thereby forming an annular space 34 in the cylindrical body 31 of the smoke distribution device 3 to receive th...

no. 3 example

[0060] Fig. 7(a) and Fig. 7(b) show a schematic structural diagram of a smoke distributing device according to a third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the second end 312 of the smoke distribution device 3 is provided with a transition section 3120 connected to the fan inlet, so as to adapt to different spatial arrangements of various industrial furnaces. The transition section 3120 may have a taper such as a cone for direct or indirect connection with the fan inlet. The transition section 3120 may also have a straight portion connected to the tapered portion, and the straight portion may be directly or indirectly connected to the fan inlet. However, the transition section 3120 may also take other cylindrical shapes as long as it is properly connected to the fan inlet for supplying combustion air.

[0061] Figure 7(a) shows that the air inlet 32 is arranged close to the second end 312 of the smoke d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com