Reaction Injection Molding System Based on Dicyclopentadiene

A dicyclopentadiene and injection molding technology, applied in the field of injection molding, can solve the problems of high resistance in the filling process, influence on coating, low efficiency and low product qualification rate, and achieve the effect of realizing intelligent and precise control and overcoming waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

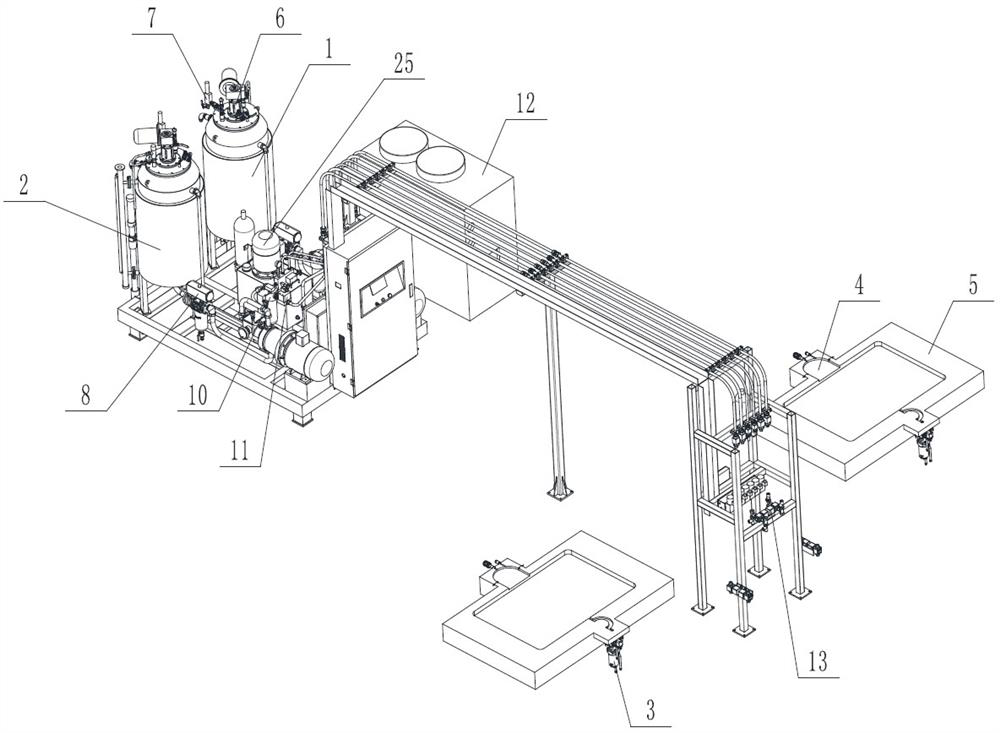

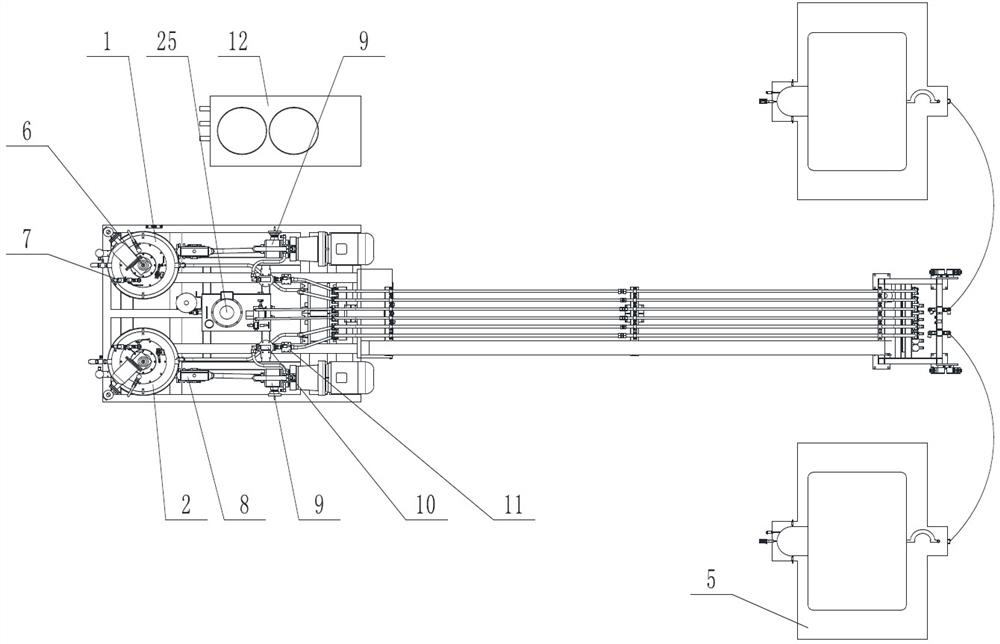

[0049] like figure 1 and figure 2 The shown reaction injection molding system based on dicyclopentadiene includes a first material tank 1 and a second material tank 2, and the first material and the second material are respectively transferred from the first material tank 1 and the second material tank through a pumping system. 2 is delivered to the mixing head 3; also includes a mold 5 for dicyclopentadiene reaction injection molding, the overflow bag 4 communicated with the inside of the mold cavity is set on the mold 5, and the mixing head 3 and the overflow bag 4 are set On opposite sides of the mold 5 , the mixing head 3 is used to pour the mixed raw materials into the mold 5 , and the overflow bag 4 is provided with a liquid level sensor 14 ; The first material tank 1 and the second material tank 2 are equipped with a stirring device 6 and a vacuum generating device 7 .

[0050] It should be noted that, for the convenience of illustration, the mold 5 in the drawings o...

Embodiment 2

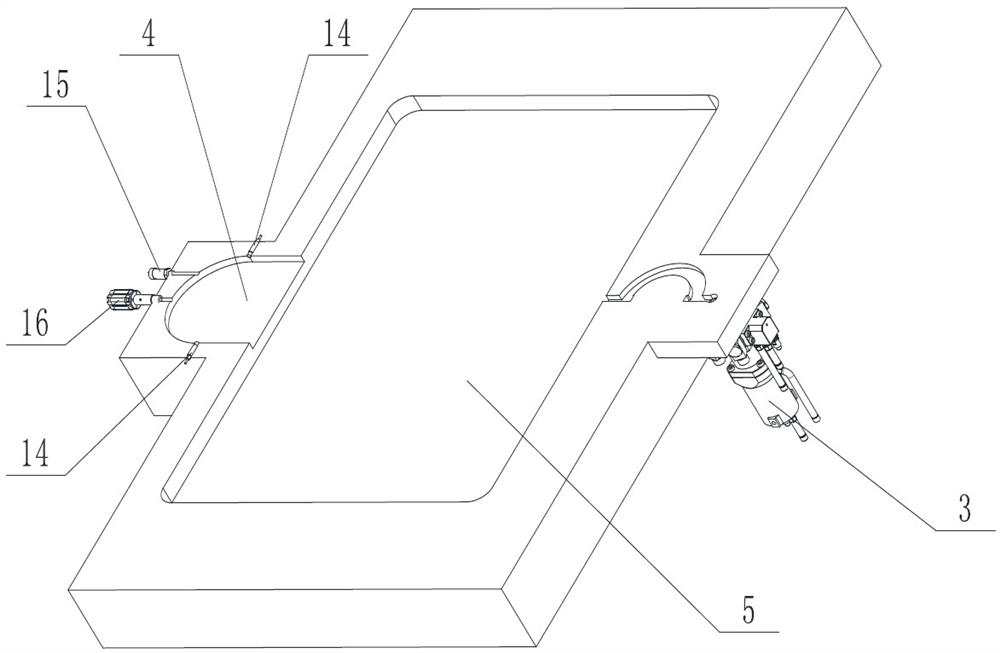

[0058] On the basis of Example 1, such as image 3 As shown, a pressure sensor 15 located in the overflow bag 4 is also included, and the pressure sensor 15 is located on the side of the liquid level sensor 14 away from the mold cavity. It also includes an exhaust valve 16 arranged on the overflow bag 4 .

[0059] In one or more preferred embodiments, the exhaust valve 16 is as Figure 7 and Figure 8 As shown, it includes a housing 161 and an exhaust pin 162 slidingly fitted in the housing 161. There are several exhaust gaps 163 between the exhaust pin 162 and the housing 161; an exhaust port is set on the housing 161 24 , the exhaust port 24 communicates with the exhaust gap 163 . Also comprise the cleaning device that is used to push exhaust pin 162 out housing 161; Said cleaning device comprises the cleaning cylinder 17 that links to each other with exhaust valve 16, the reversing valve 18 that matches with cleaning cylinder 17, and described cleaning cylinder 17 The o...

Embodiment 3

[0065] On the basis of any of the above-mentioned embodiments, a switching valve 13 is also provided between the flow meter 11 and the mixing head 3; the switching valve 13 includes a first station and a second station:

[0066] When the switching valve 13 is at the first station, the first raw material and the second raw material enter the mixing head 3;

[0067] When the switching valve 13 is at the second position, the first raw material and the second raw material flow back to the first material tank 1 and the second material tank 2 respectively.

[0068] The switching valve 13 of the present embodiment is as Figure 4 to Figure 6 As shown, it includes two valve bodies 131 respectively corresponding to the first raw material and the second raw material, and each valve body 131 is clearance fit with the valve core 132, and the valve body 131 is connected with two three-way joints 133; Based on the driving mechanism that drives the spool 132 to move, the spool 132 can conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com