Device for checking a turbomachine engine

A technology of engines and turbines, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as difficulties and inaccessibility of non-destructive testing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

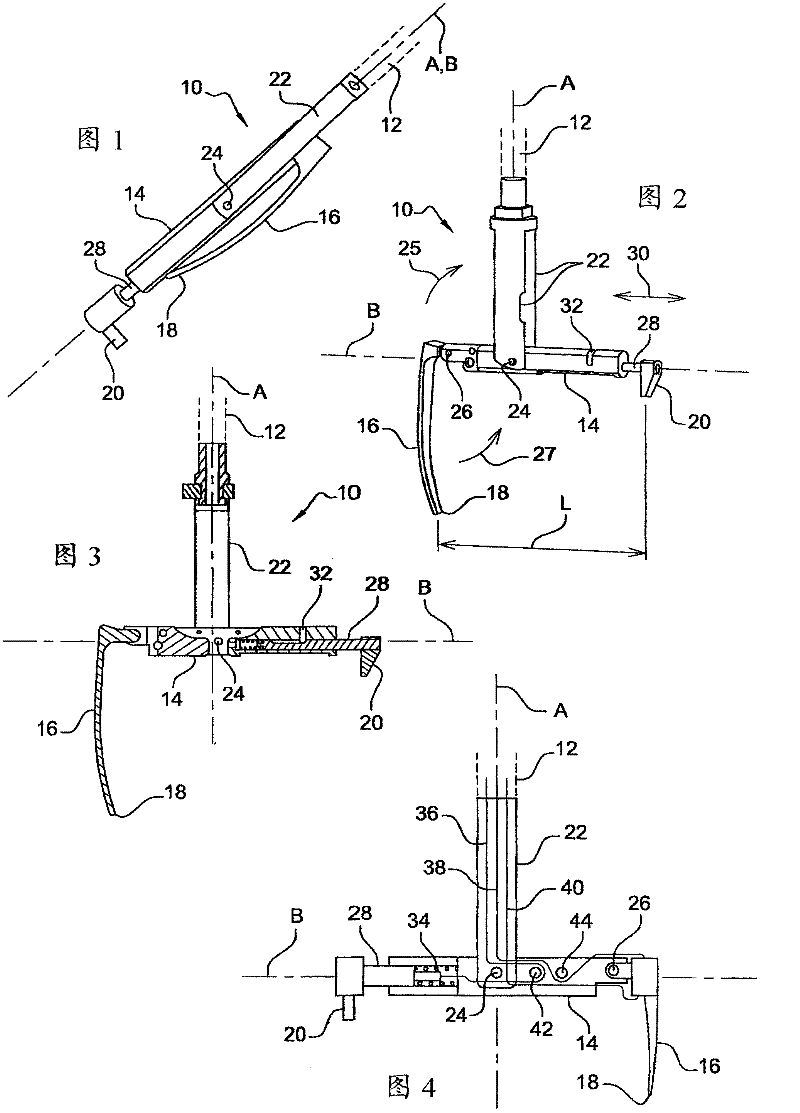

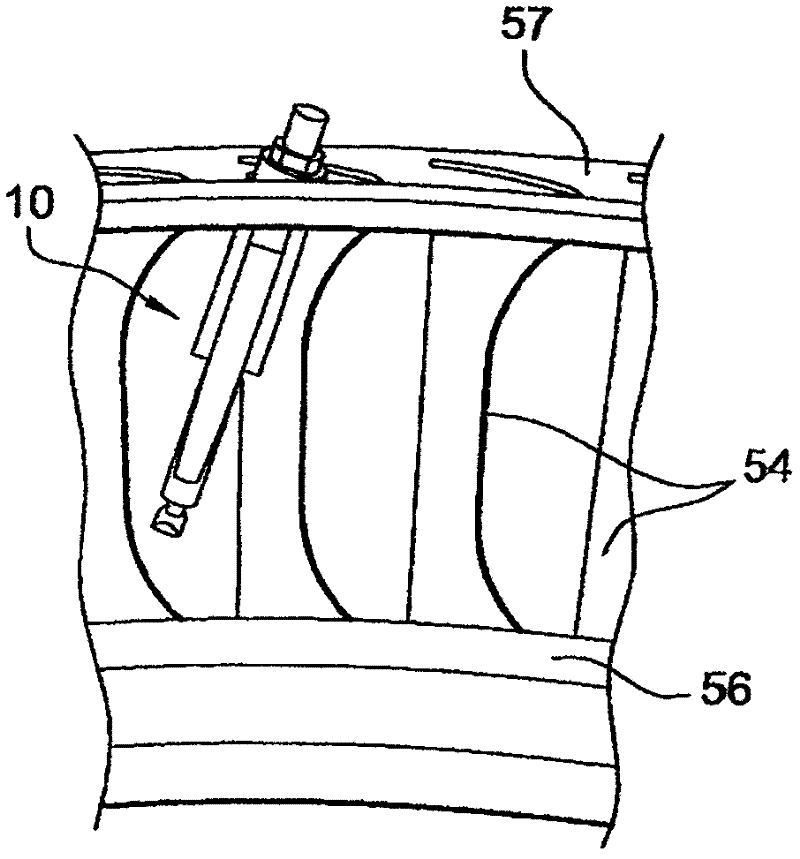

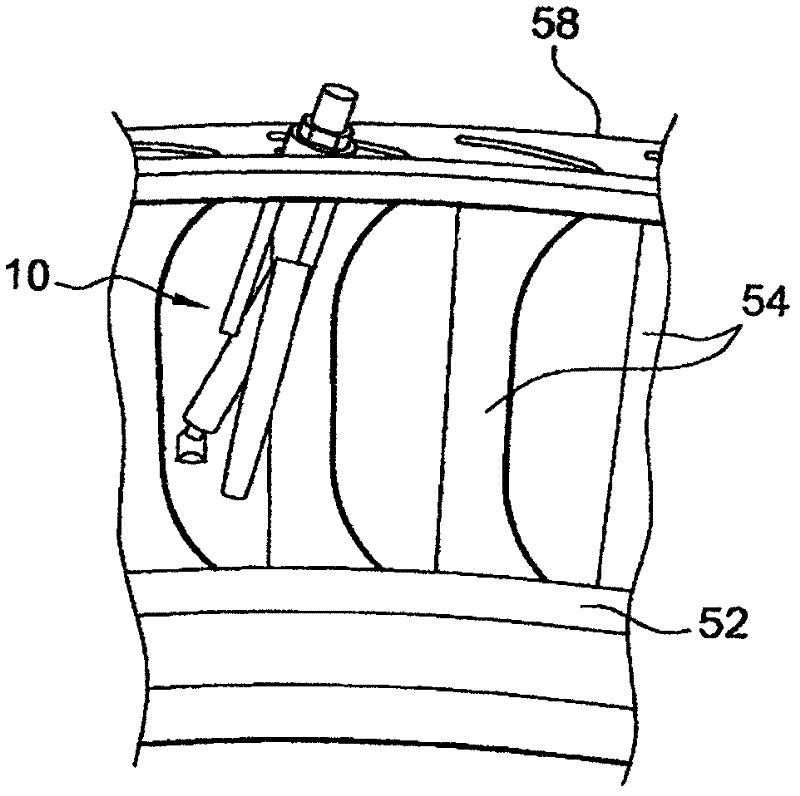

[0026] see first Figures 1 to 4 , which shows an apparatus 10 of the present invention for non-destructive inspection of turbine engine components hereinafter referred to Figures 5 to 8 is partially described.

[0027] Apparatus 10 includes a longitudinal rod 12 (shown in phantom) having a finger 14 pivotally mounted at its distal end, which carries at one end a blade 16 for supporting an inspection probe 18, and at its The opposite end carries a slider 20 for bearing against and / or gripping on an element of the engine.

[0028] The rod 12 carries at its distal end two parallel spaced apart longitudinal lugs 22 , the fingers 14 being pivotally mounted by means of their intermediate portions on pins 24 extending between the free ends of the lugs 22 .

[0029] Finger 14 can be used as figure 1 The folded position shown in where it extends between the lugs parallel to the longitudinal axis A of the rod is the same as Figures 2 to 4 Pivotal movement (arrow 25 ) between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com