Fixer tool for automobile sun shield

A technology for automobile sun visors and fixers, which is applied to manufacturing tools, hand-held tools, etc., can solve the problems of lack of good force points and laborious manual assembly, and achieve the effects of ensuring quality, saving time in assembly, and high working accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

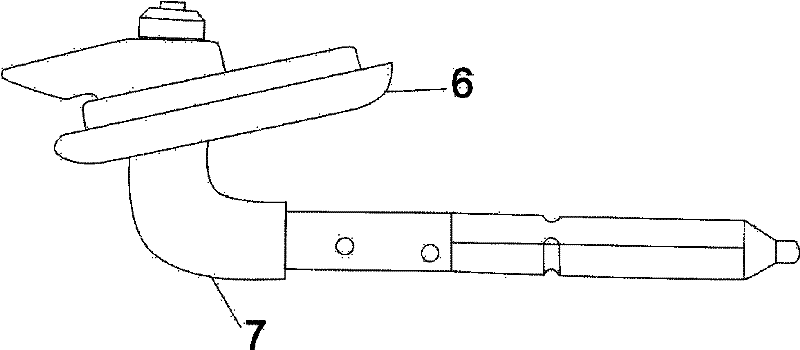

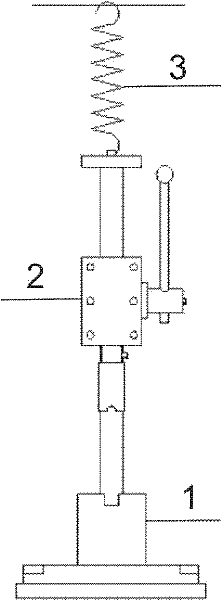

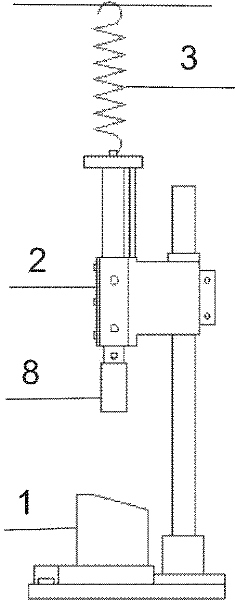

[0015] As shown in the figure: an automobile sun visor fixer tool, which is composed of a fixer cap fixing block 1, a mechanical extruder 2 and a return spring 3. The base of the mechanical extruder is fixedly equipped with a fixer cap fixing block as a die of the mechanical extruder, the fixing block is a trapezoidal structure, and a connection fixing hole 4 for the fixer cap and the fixer rod is opened on it; The top of the extruder is equipped with a return spring. The shape and size of the above-mentioned retainer cap fixing block match the retainer cap. The punch 8 of the above-mentioned mechanical extruder is provided with an arc-shaped opening 5 that can hold the retainer rod. The working process of the present invention is: at first set the retainer cap 6 on this trapezoidal fixed block, and after making the connecting hole on the retainer cap and the retainer rod 7 to be opposite to the connection fixing hole on the retainer block, then attach the retainer Insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com