Method for renewing tyre by using pre-sulfurized annular tyre surface

A tread retreading and pre-vulcanization technology, which is applied in tires, applications, household appliances, etc., can solve the problems of complex control systems and methods, long vulcanization time, and low production efficiency, so as to shorten the retreading process time, simplify the vulcanization process, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In Embodiment 1, the method for retreading a tire with a precured annular tread includes the following steps:

[0060] Adopt pre-vulcanization process to make continuous annular tread;

[0061] For tires that need to be retreaded, sand the crown of the carcass;

[0062] The back side of the ring tread is polished to the same roughness RMA as the tire crown of the carcass, and the RMA is between 3 and 4;

[0063] Coat the normal temperature vulcanizing agent evenly on the surface of the carcass crown;

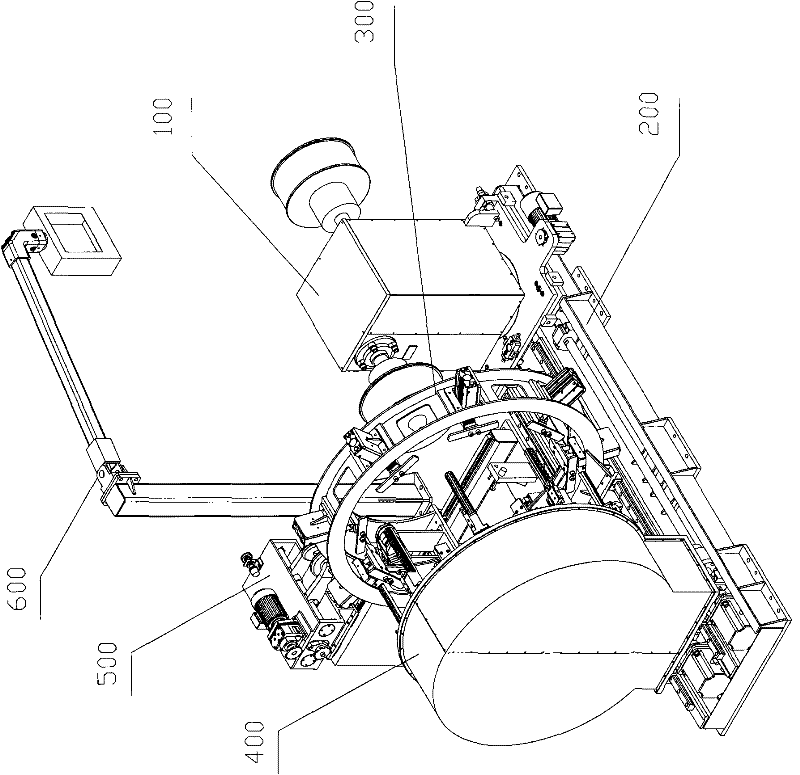

[0064] Use a radial expansion device to coaxially wrap the annular tread on the outer circumference of the tire;

[0065] At an ambient temperature of 40±5℃, apply 8-11kg / cm between the annular tread and the carcass. 2 After 45-75 minutes of pressure, the annular tread and the carcass are vulcanized to form an integral structure.

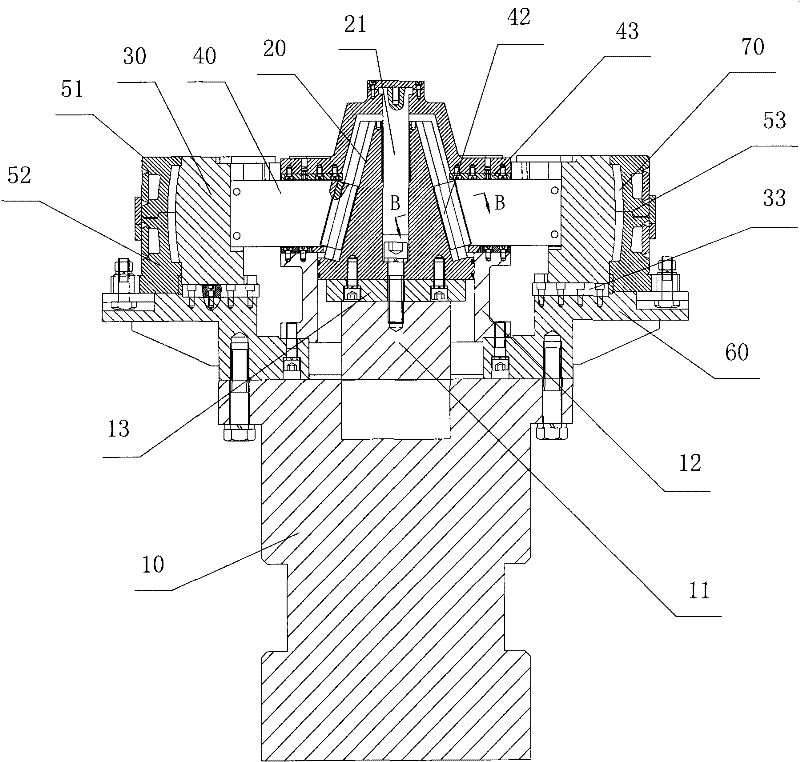

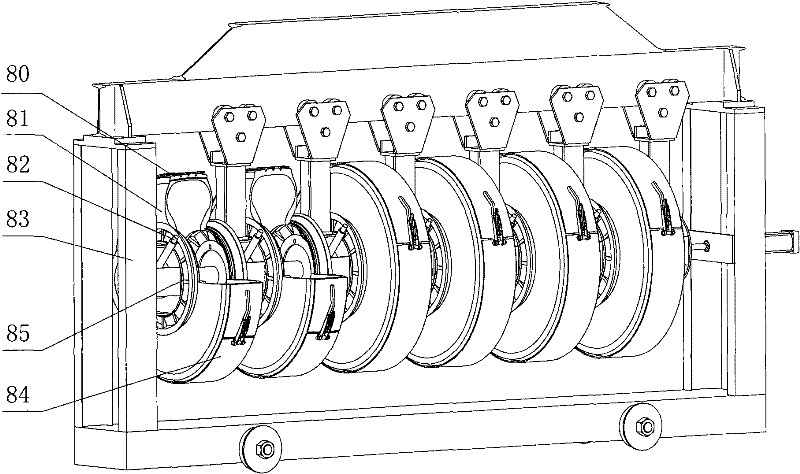

[0066] Such as figure 1 As shown, the method steps of pre-vulcanizing toroidal tread are as follows,

[0067] Rubber mixing process, mixing the raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com