Reverse type self-luminous reflecting mirror

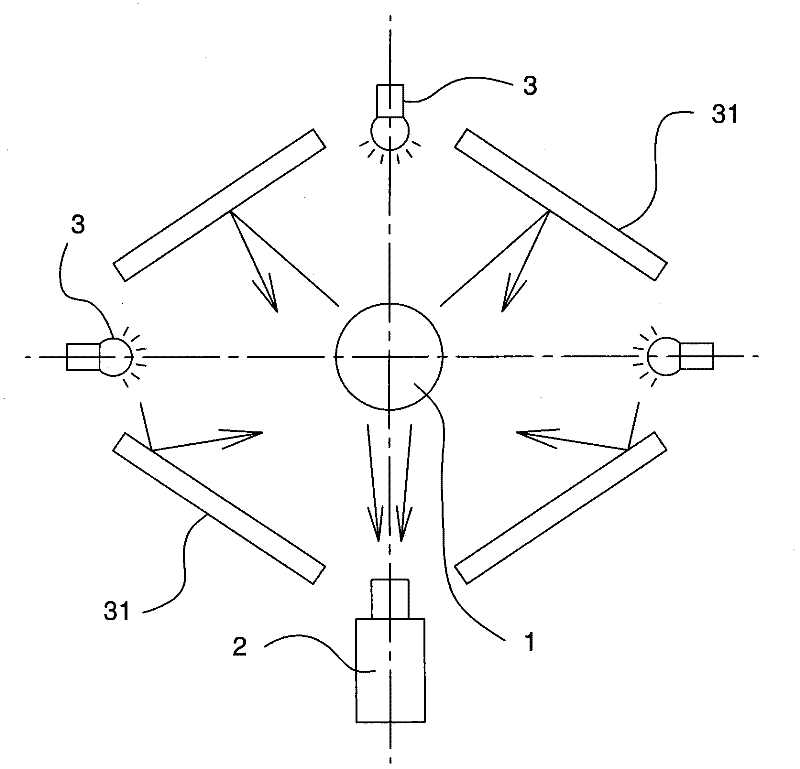

A self-luminous, mirror technology, applied in the direction of reflector, light source, refractor, etc., can solve the problems of affecting the imaging quality, image comparison misjudgment, etc., to improve the imaging quality and avoid the effect of directly illuminating the camera lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

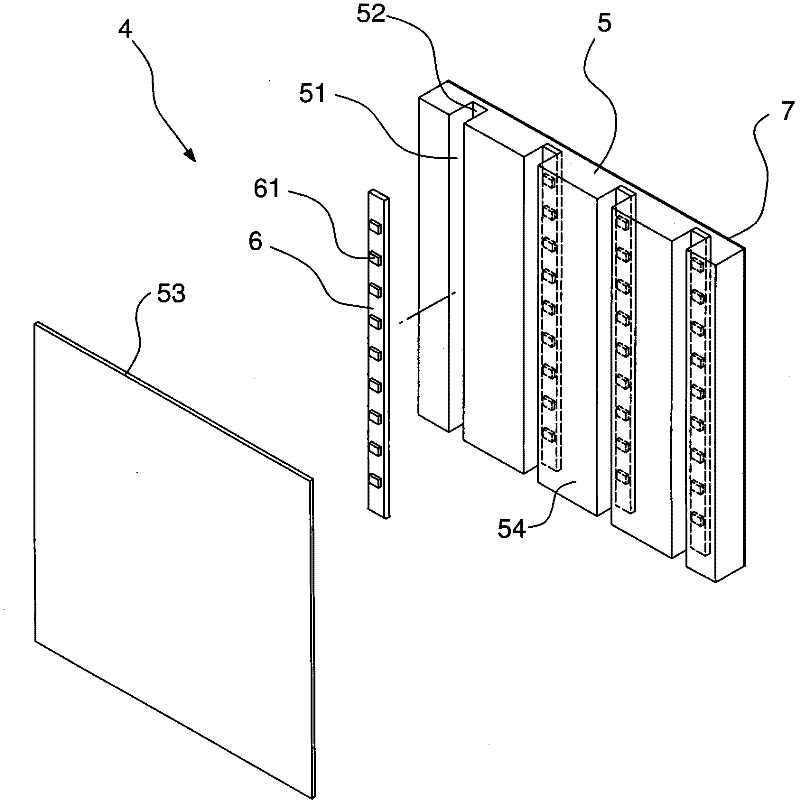

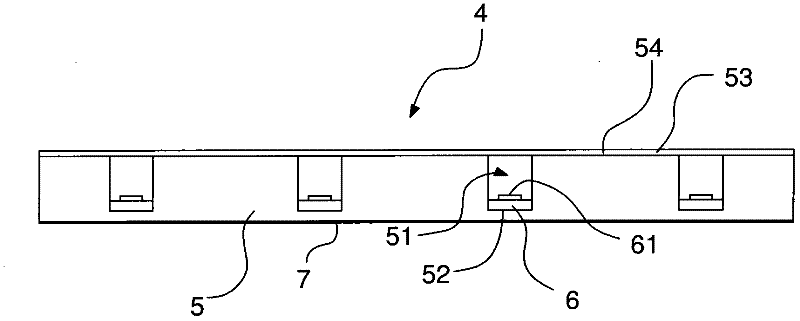

[0014] The description of the following embodiments refers to the attached drawings to illustrate specific embodiments in which the present invention can be implemented. The directional terms mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", "top", "bottom", etc., are only for reference to additional drawings direction. Therefore, the directional terms used are used to describe and understand the present invention, rather than to limit the present invention.

[0015] Please refer to Figure 2 to Figure 4 The reverse self-luminous reflector of the present invention shown, wherein figure 2 It is a three-dimensional exploded view of the reverse self-luminous mirror of the present invention; image 3 It is the combined side view of the reverse self-luminous reflector of the present invention; Figure 4 It is a partial cross-sectional view of the combined reverse self-luminous mirror of the present invention; Figure 5 It is a schematic diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com