Planter

A technology for planting machines and planting parts, applied in the field of planting machines, which can solve the problems of difficulty in forming bulb openings, low operating efficiency, and difficulty in changing the distance between planting bulbs, etc., to achieve low-cost manufacturing, reduce the number, and prevent developmental obstacles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

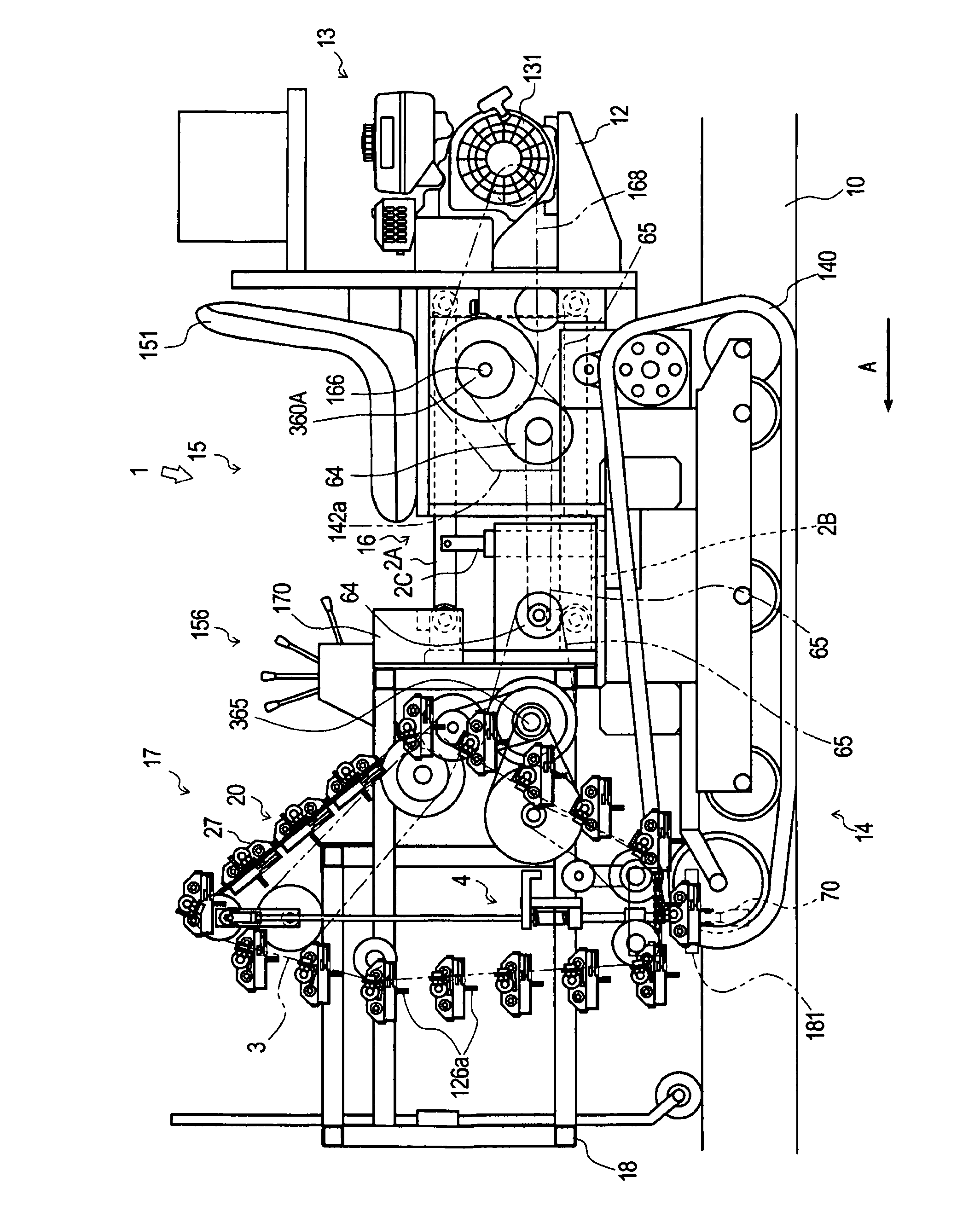

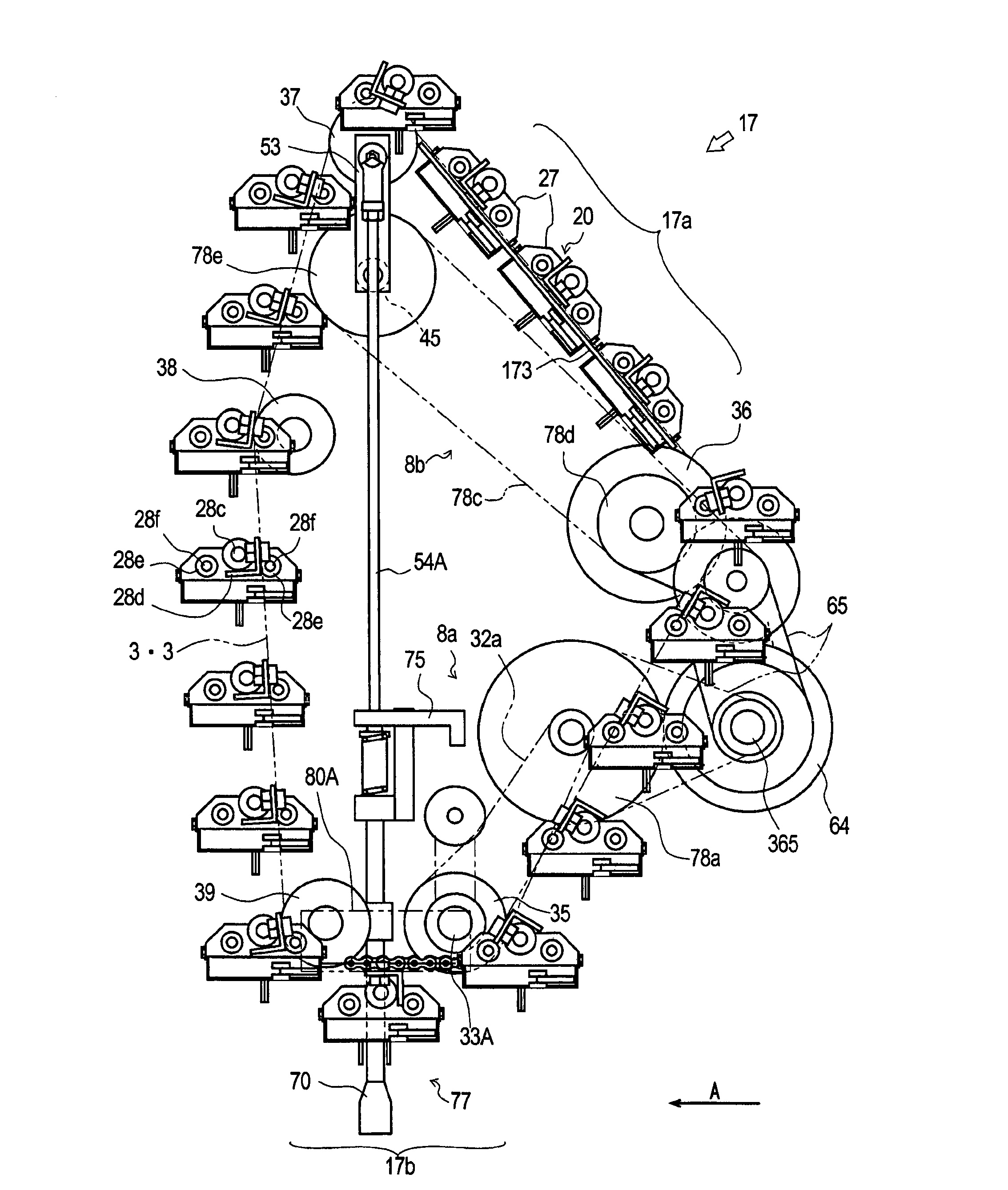

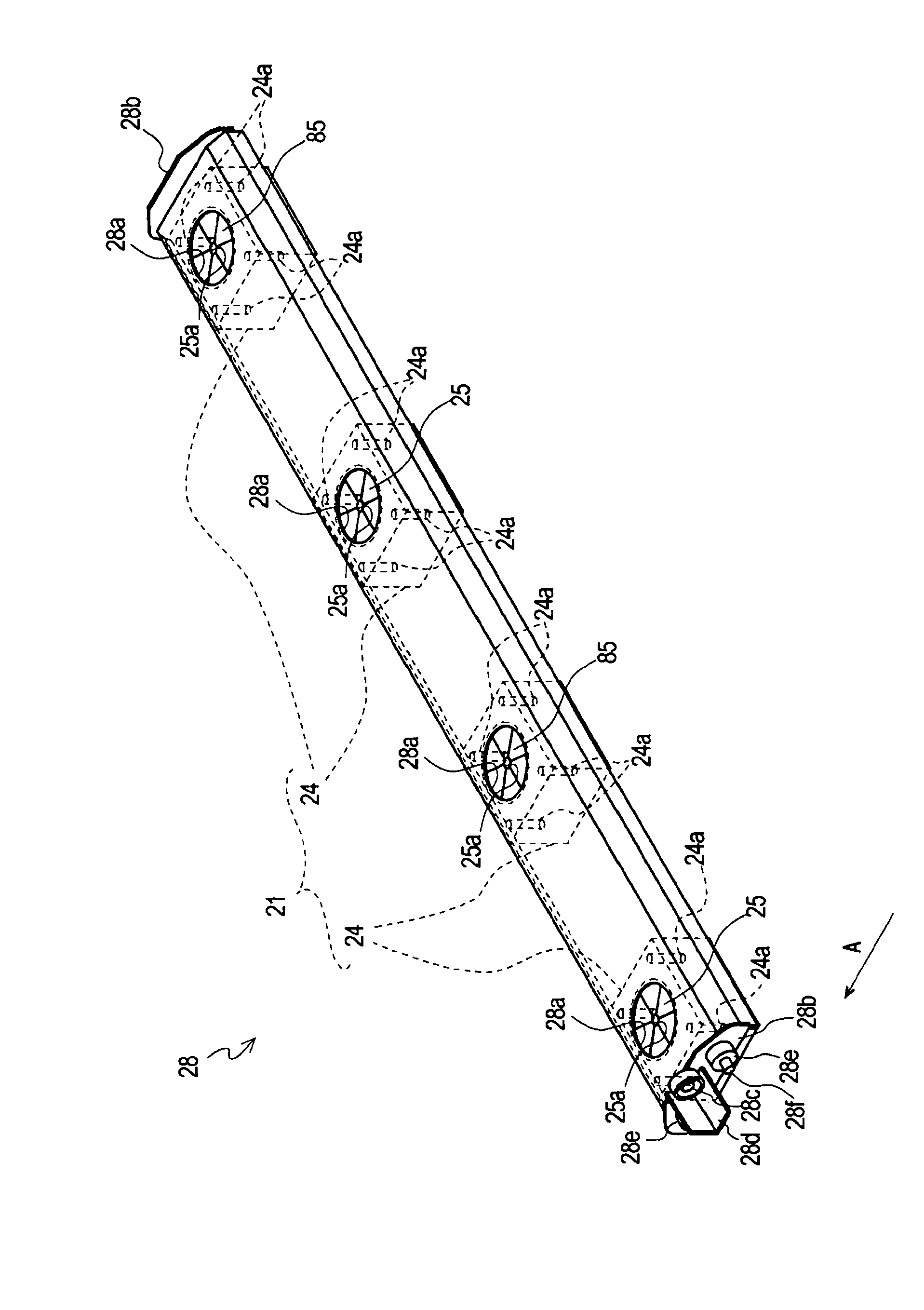

[0068] Below, refer to figure 1 and figure 2 . The overall structure of the planting machine according to the first embodiment of the present invention will be described.

[0069] In addition, in the following description, the direction of the arrow A shown in a figure is set as the front direction of the planter 1, and the front, back, left, and right directions are prescribed|regulated.

[0070] In addition, in this embodiment, it is assumed that bulbs such as garlic are planted on a field covered with multi-layer sheets on the field ridge, but it is not limited to this. Planting bulbs, for example, can also be done on roughly flat fields.

[0071] The planter 1 is used for planting bulbs such as garlic on a field (field ridge) covered by multi-layer sheets.

[0072] Such as figure 1 As shown, the planter 1 is equipped with: a body frame 12 , a driving part 13 , a driving part 14 , an operating control part 15 , a power transmission mechanism 16 , and a planting part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com