Multifilament conductor and method for producing same

A multi-filament conductor and structure technology, applied in the manufacture/processing of superconductor devices, permanent superconductor devices, superconductive devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

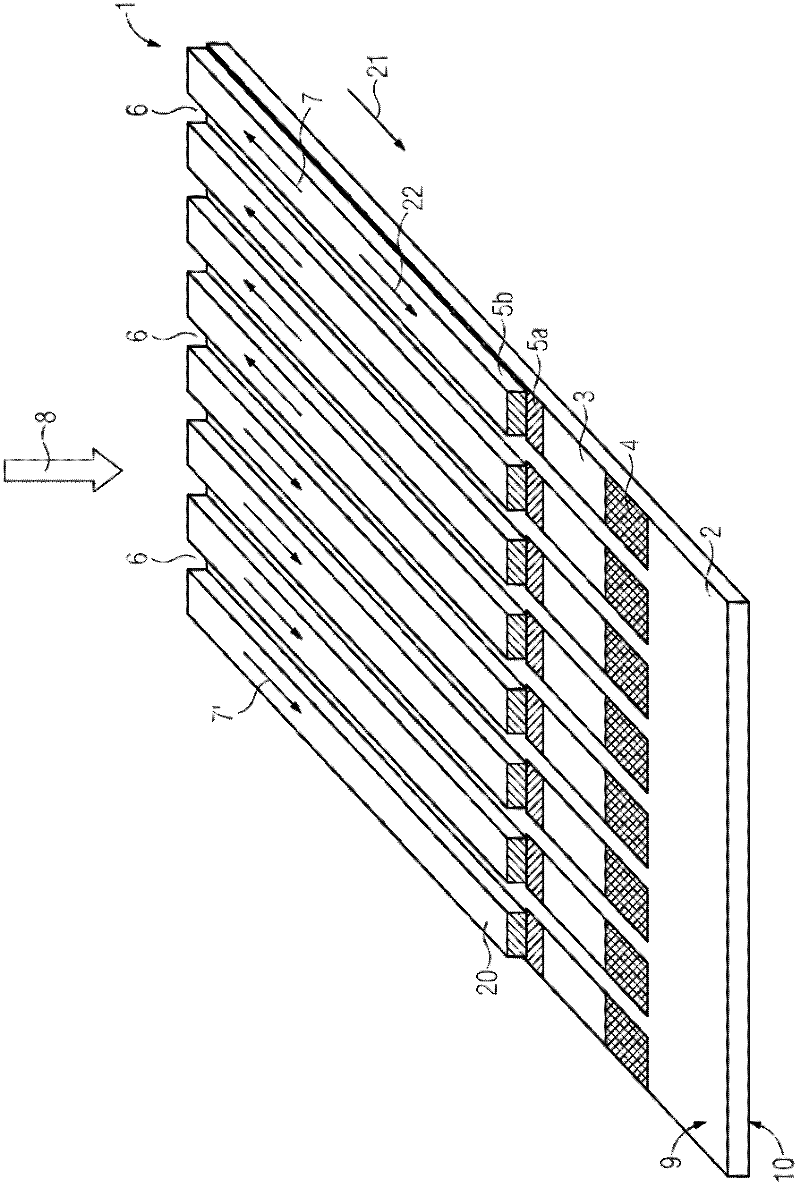

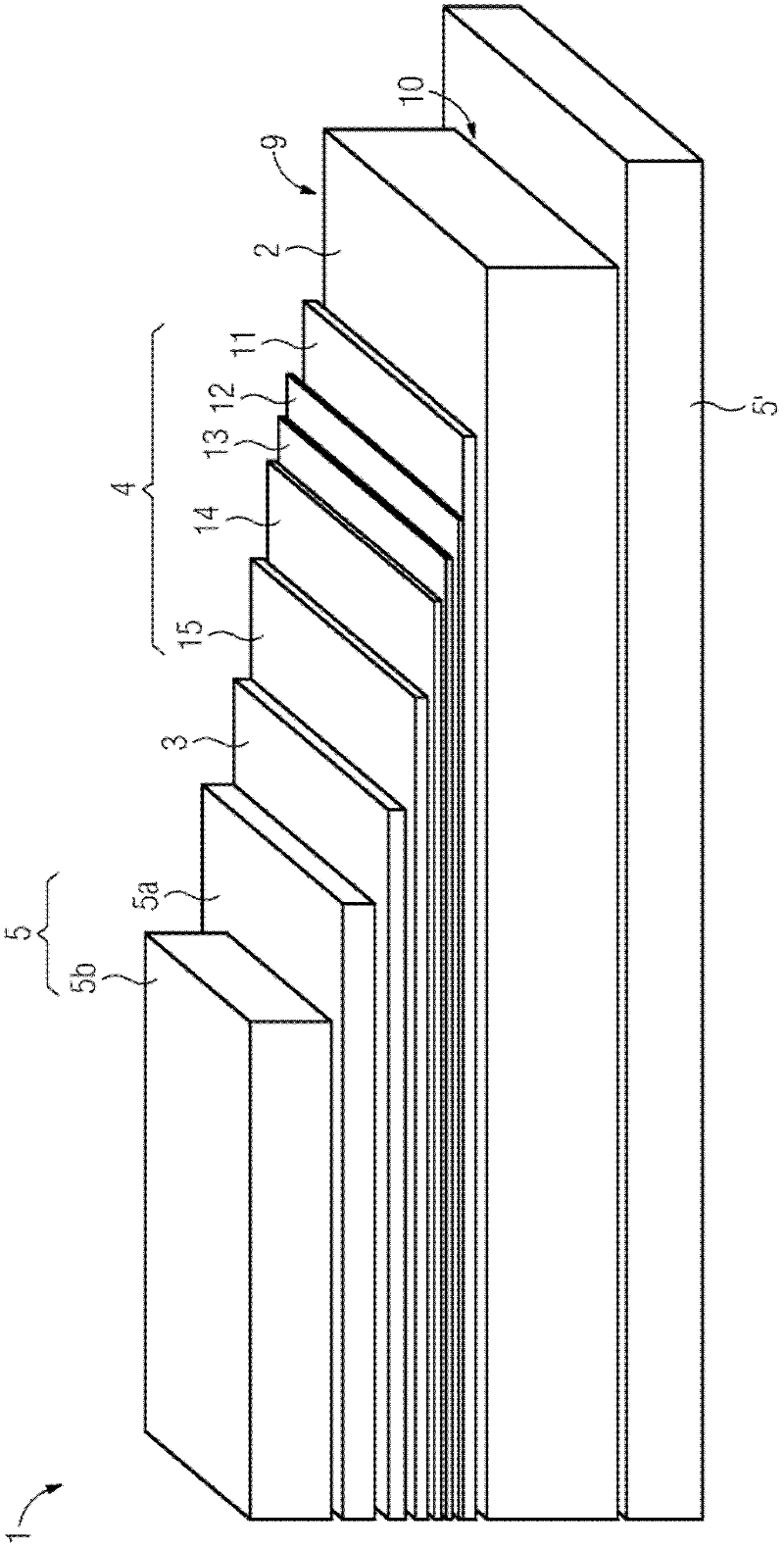

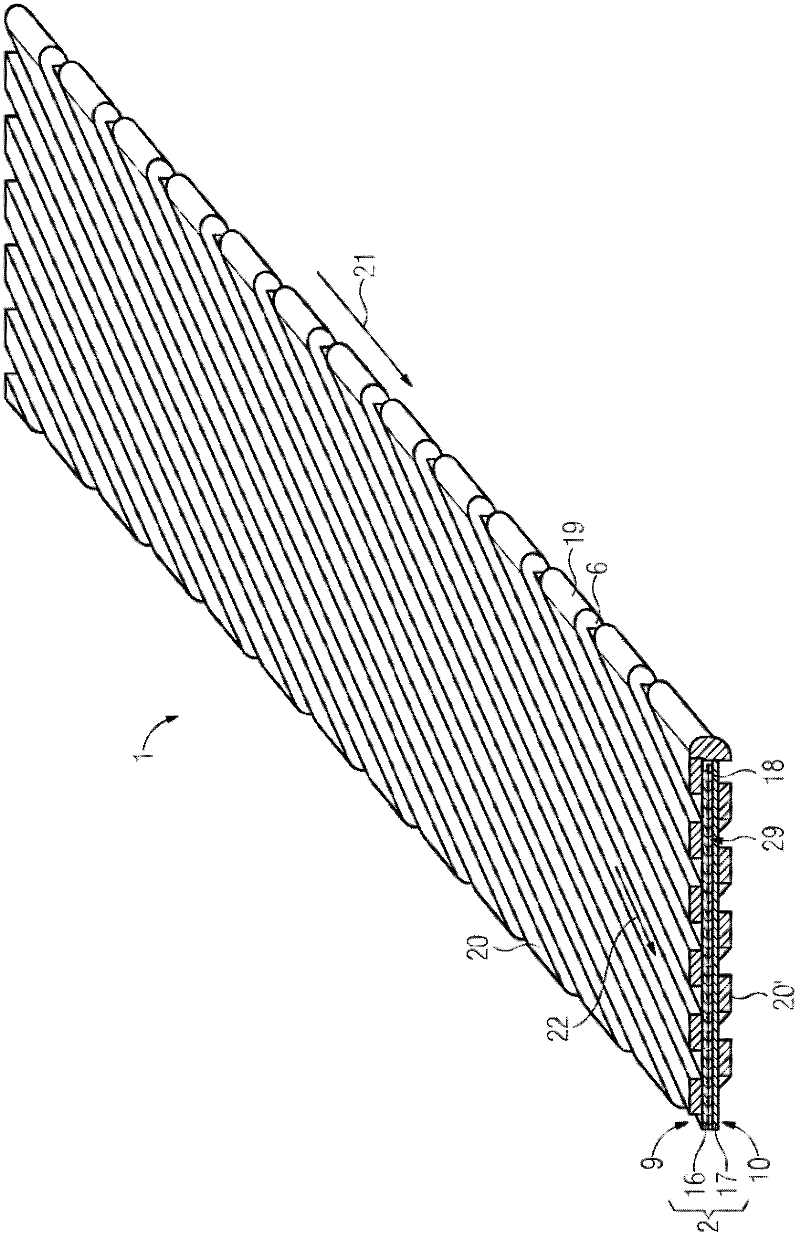

[0043] FIG. 1 shows the layers perpendicular to the longitudinal axis of the multi-filament conductor 1 according to the prior art in an oblique view from the front of the multi-filament conductor 1 . The multifilament conductor 1 has a strip-shaped substrate 2 with a front side 9 and a rear side 10 . The first direction 21 of the tape-shaped substrate 2 is defined as the longitudinal direction of the tape-shaped substrate 2 . Strip-shaped parallel strips of the buffer layer 4 are applied parallel to the first direction 21 on the front side 9 of the strip-shaped substrate 2 . The strips of cushioning layer 4 are spaced apart from each other and have a second direction 22 corresponding to the longitudinal direction of the strips of cushioning layer 4 . On the strips of the buffer layer 4 a superconducting layer 3 is formed, for example of YBCO material. A thin silver layer (Ag layer) 5 a and a copper layer (Cu layer) 5 b are formed on the superconducting layer 3 as a protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com