Enhanced impeller for liquid pump

A reinforced, liquid pump technology, used in liquid fuel engines, pumps, components of pumping devices for elastic fluids, etc. Strong, not easy to bend and deform, good stability

Inactive Publication Date: 2012-06-06

SHANDONG SHUANGLUN

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem solved by the present invention is to solve the problem that the blades protrude beyond the front cover, and the axial dimension of the impeller is relatively long, resulting in insufficient rigidity of the helical blades, low strength, poor stability, and the blades are easy to bend, deform, or even break, and provide a rigid helical blade. Strong, high strength, good stability, the blades are not easy to bend and deform, the blades are not easy to break, stable and reliable liquid pump reinforced impeller

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

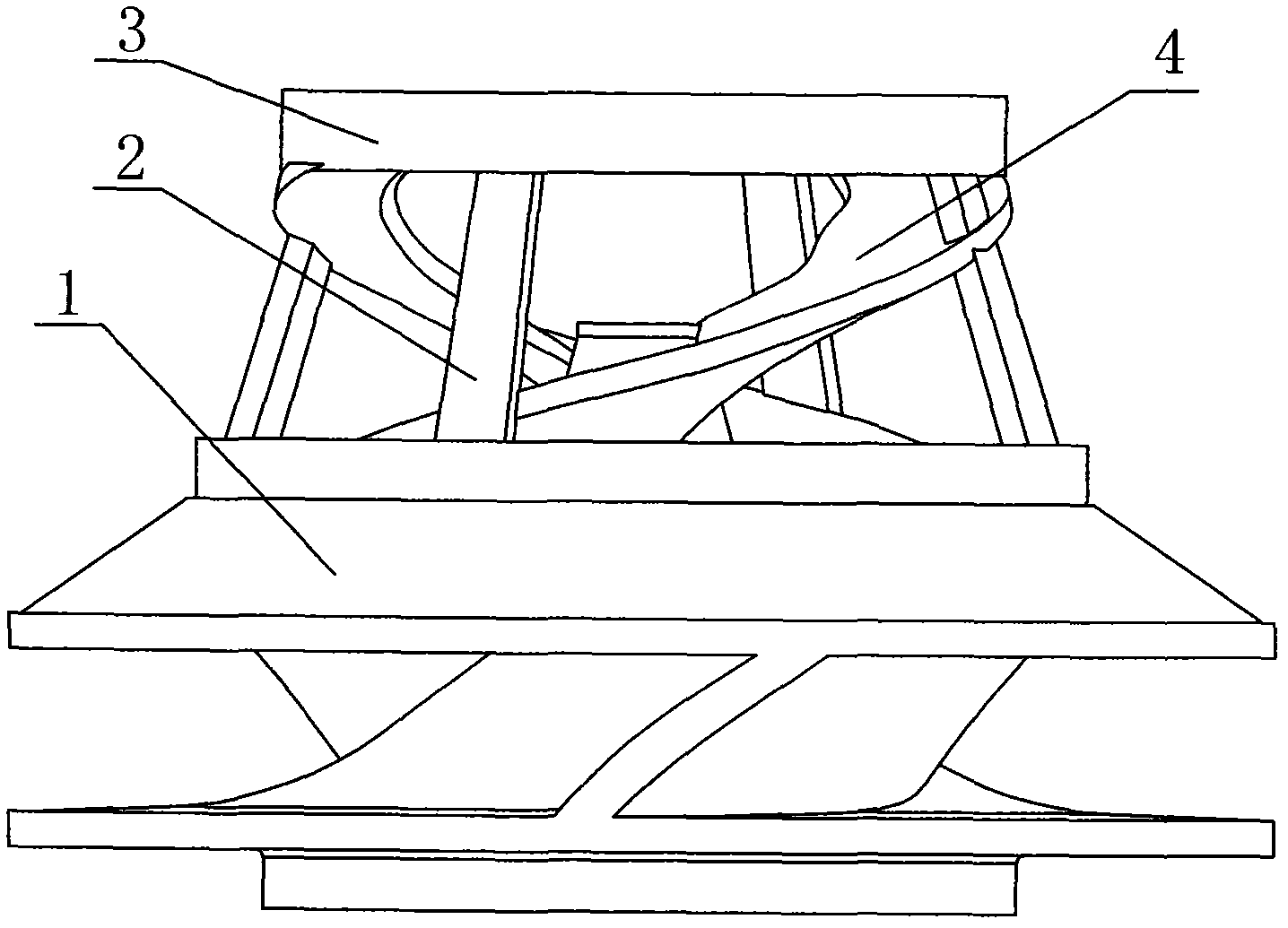

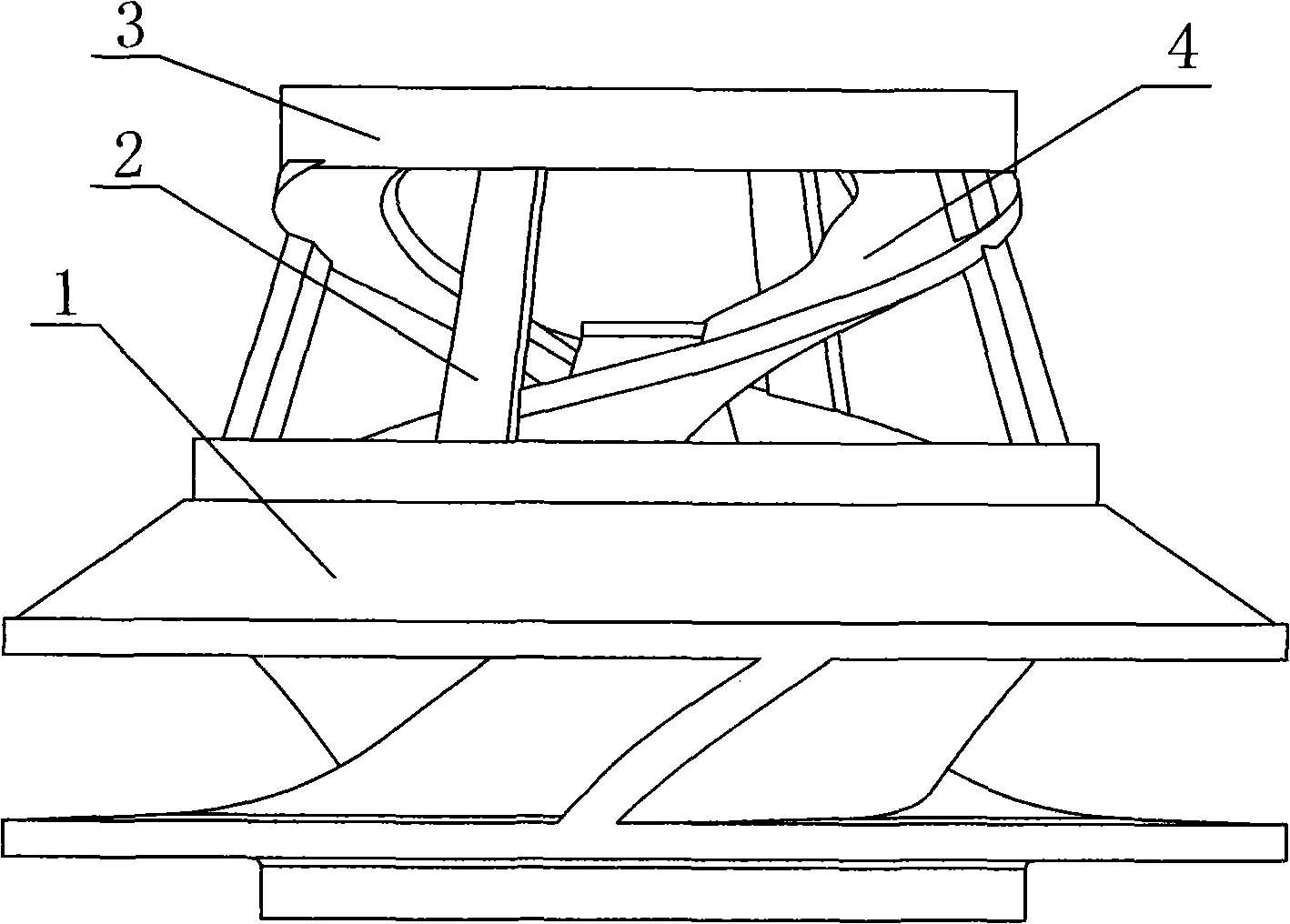

[0007] The reinforced impeller of the liquid pump as shown in the figure is provided with a helical impeller, and the helical impeller is provided with a helical blade 4, and the helical blade 4 is provided with a front cover plate 1, and the front end of the helical blade 4 is provided with a hoop 3, and the hoop 3 and Ribs 2 are evenly distributed between the front cover plate 1, and the helical blade 4 has strong rigidity, high strength and good stability.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses an enhanced impeller for a liquid pump and relates to a liquid pump. The enhanced impeller is provided with a spiral impeller, wherein a spiral blade is arranged on the spiral impeller; a front cover plate is arranged on the spiral impeller; a hoop is arranged at the front end of the spiral blade; and reinforcing ribs are uniformly distributed between the hoop and the front cover plate. The hoop is arranged at the front end of the spiral blade and the reinforcing ribs are uniformly distributed between the hoop and the front cover plate, so that the enhanced impeller has the advantages that the spiral blade has strong rigidity, high strength, favorable stability and stability and reliability for operation as well as the spiral blade is not easy to bend, deform and crack. The enhanced impeller is suitable for conveying greater granular media.

Description

technical field [0001] The invention relates to a liquid pump, in particular to a liquid pump reinforced impeller. Background technique [0002] As we know, in order to ensure a large passing capacity of the existing liquid pump impeller for conveying larger granular media, the impeller adopts a double-channel spiral structure with blades extending forward. This kind of helical impeller, because the impeller adopts a double-channel spiral structure with blades protruding forward, the blades protrude beyond the front cover plate, and the axial dimension of the impeller is long, resulting in insufficient rigidity, low strength, and poor stability of the helical blades, and the blades are easy to bend and deform. even break. Contents of the invention [0003] The technical problem solved by the present invention is to solve the problem that the blades protrude beyond the front cover, and the axial dimension of the impeller is relatively long, resulting in insufficient rigidi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F04D29/22

Inventor 李智初明宇邹英杰

Owner SHANDONG SHUANGLUN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap