Backflow preventer with built-in filter screen and no external piping

A backflow preventer and filter screen technology, which is applied in filtration and separation, valve devices, chemical instruments and methods, etc., can solve problems such as hidden dangers of water supply safety, easy loss, and long structure, so as to ensure water supply safety, save installation space, and reduce costs. The effect of head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure of the backflow preventer of the present invention will be described with reference to the drawings and embodiments.

[0010] The built-in filter and the backflow preventer that does not require external piping are structures that have made major breakthroughs in the technical field.

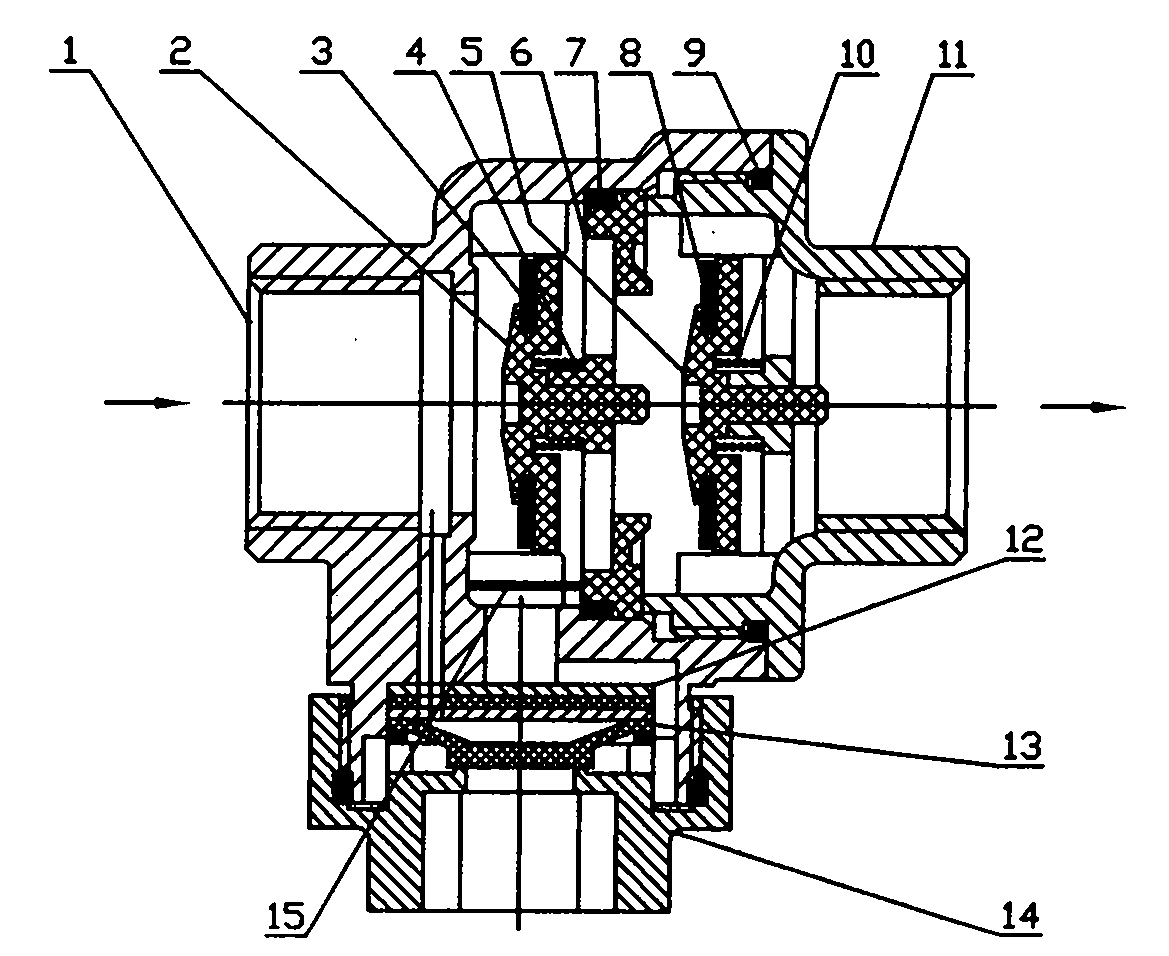

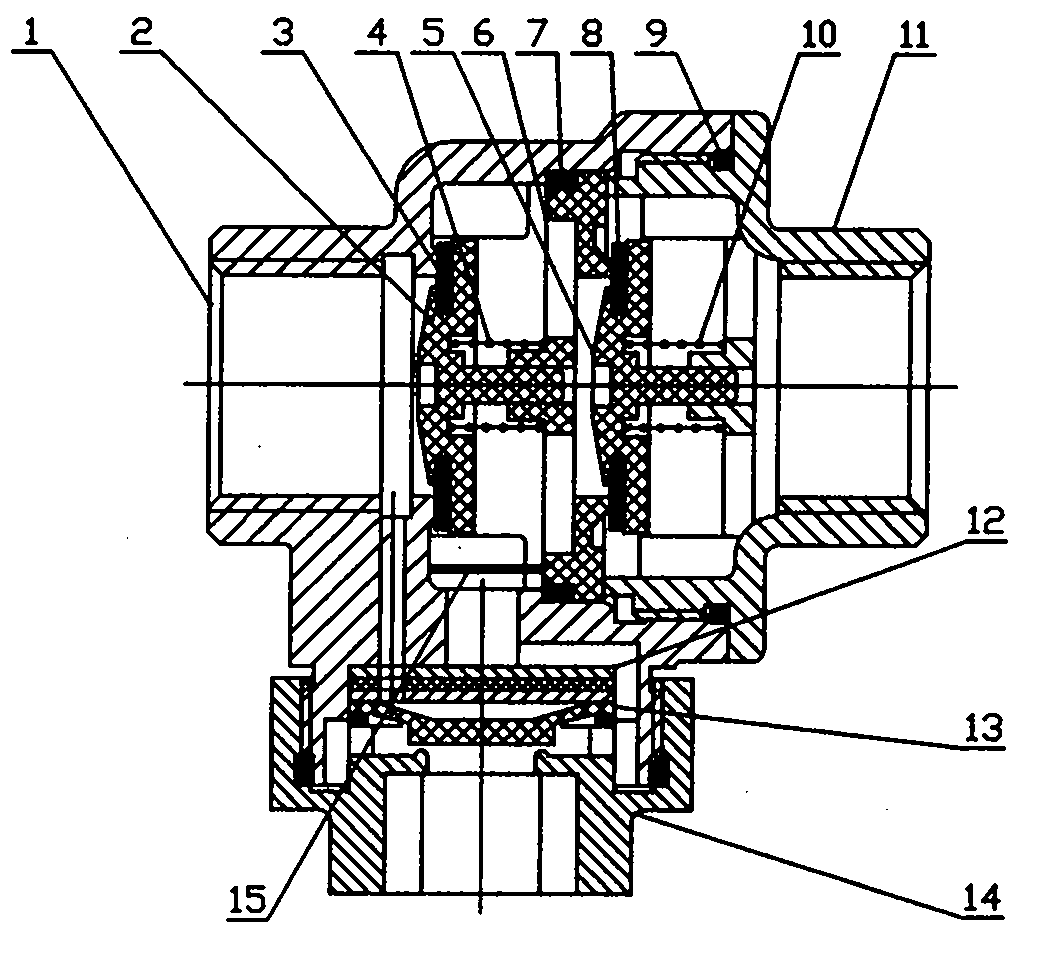

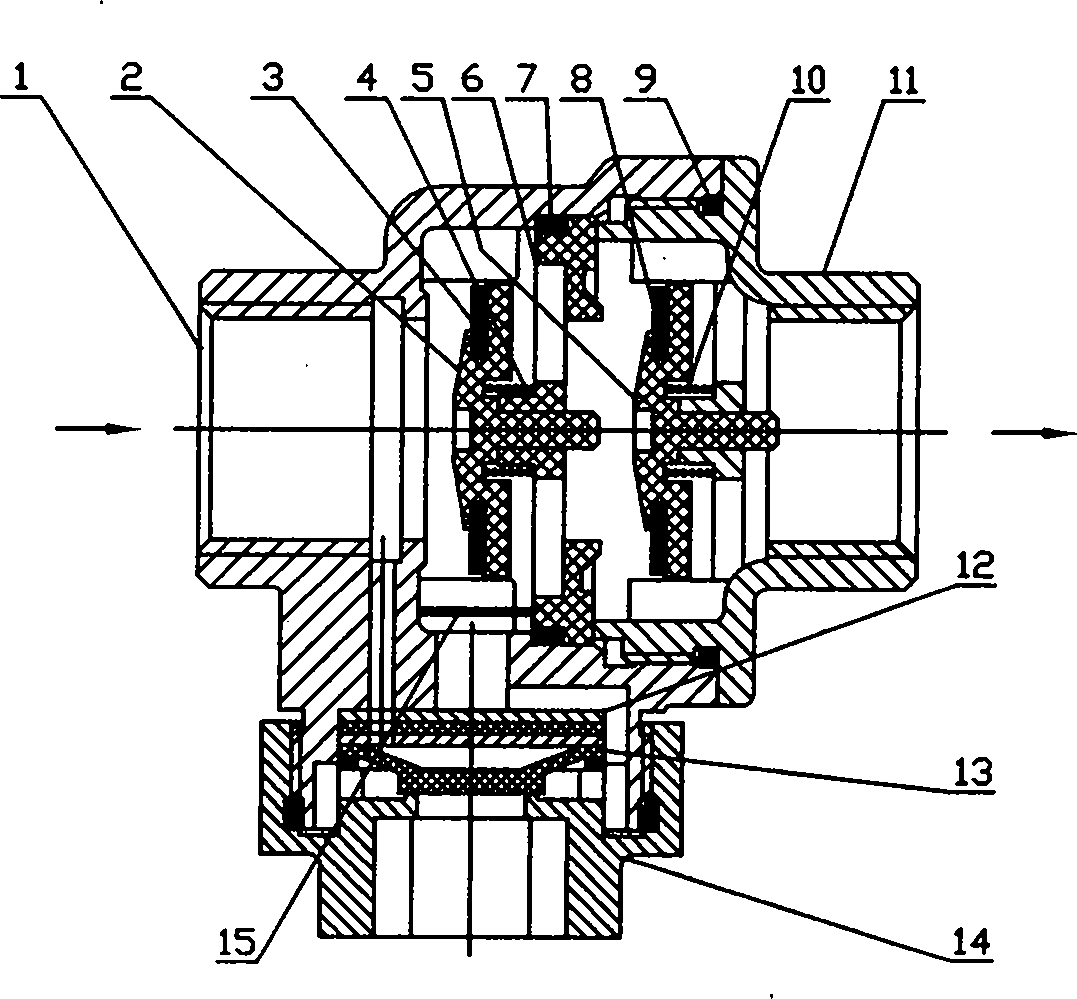

[0011] Such as figure 1 , 2 as shown, figure 1 The middle arrow indicates the direction of medium flow. A backflow preventer with a built-in filter and no external piping, the backflow preventer includes valve body one (1) and valve body two (11) connected and communicated through threads, the backflow preventer includes valve body one (1 ), valve plate one (2), sealing ring one (3), spring one (4), valve plate two (5), valve seat (6), sealing ring two (7), sealing ring three (8), seal Ring four (9), spring two (10), valve body two (11), diaphragm (12), gasket (13), lower cover (14), filter screen (15), the valve plate one (2 ) is arranged in the middle of the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com