Automatic focusing module

A technology of auto-focusing and focusing, applied in installation, optics, instruments, etc., can solve the problems of friction and peeling, unstable conduction of metal conduction layer, etc., to achieve easy manufacturing process, avoid contact conduction, and reduce the number of module parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0037] The autofocus module of the present invention will be described in detail through the following specific embodiments in conjunction with the accompanying drawings.

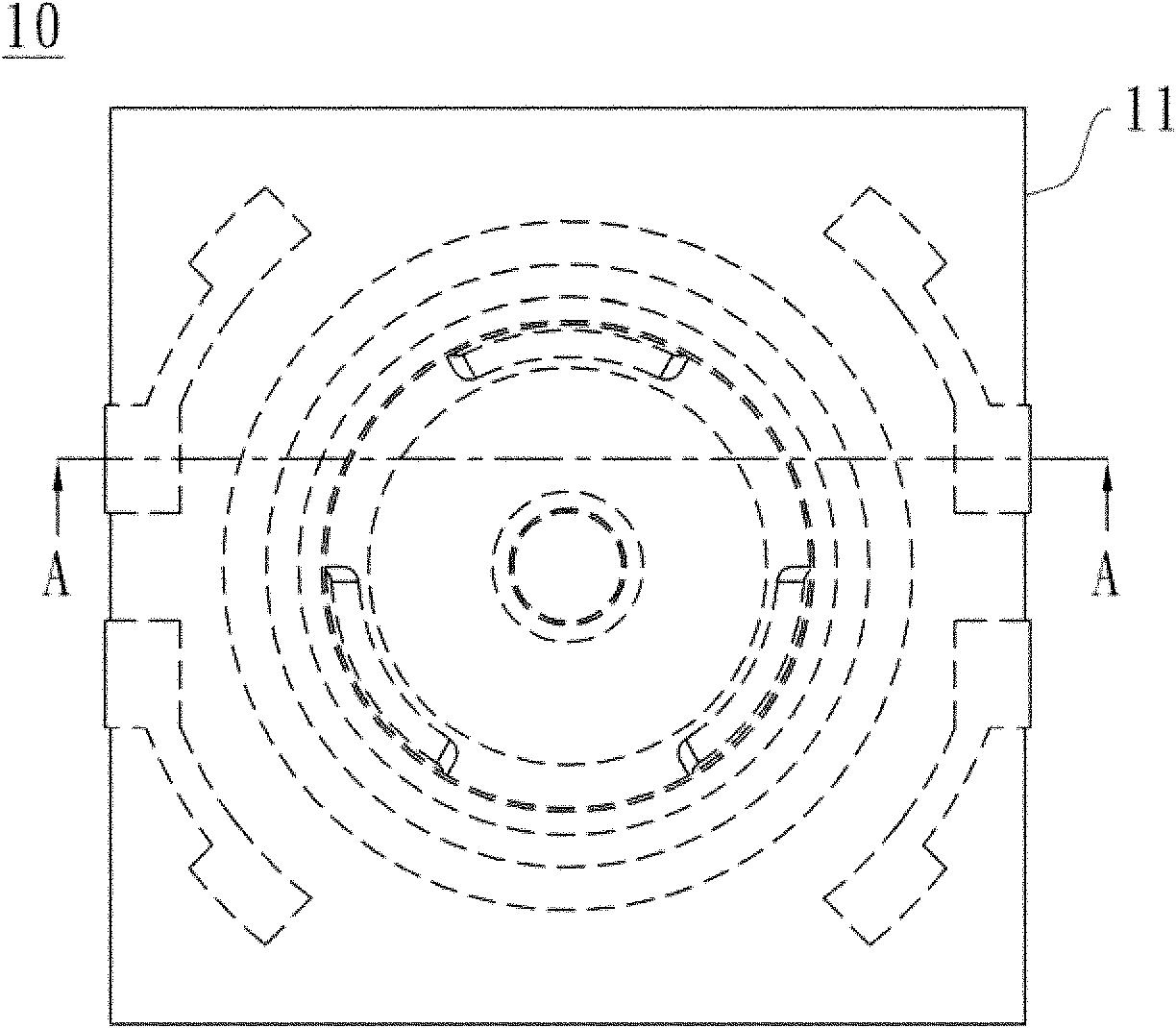

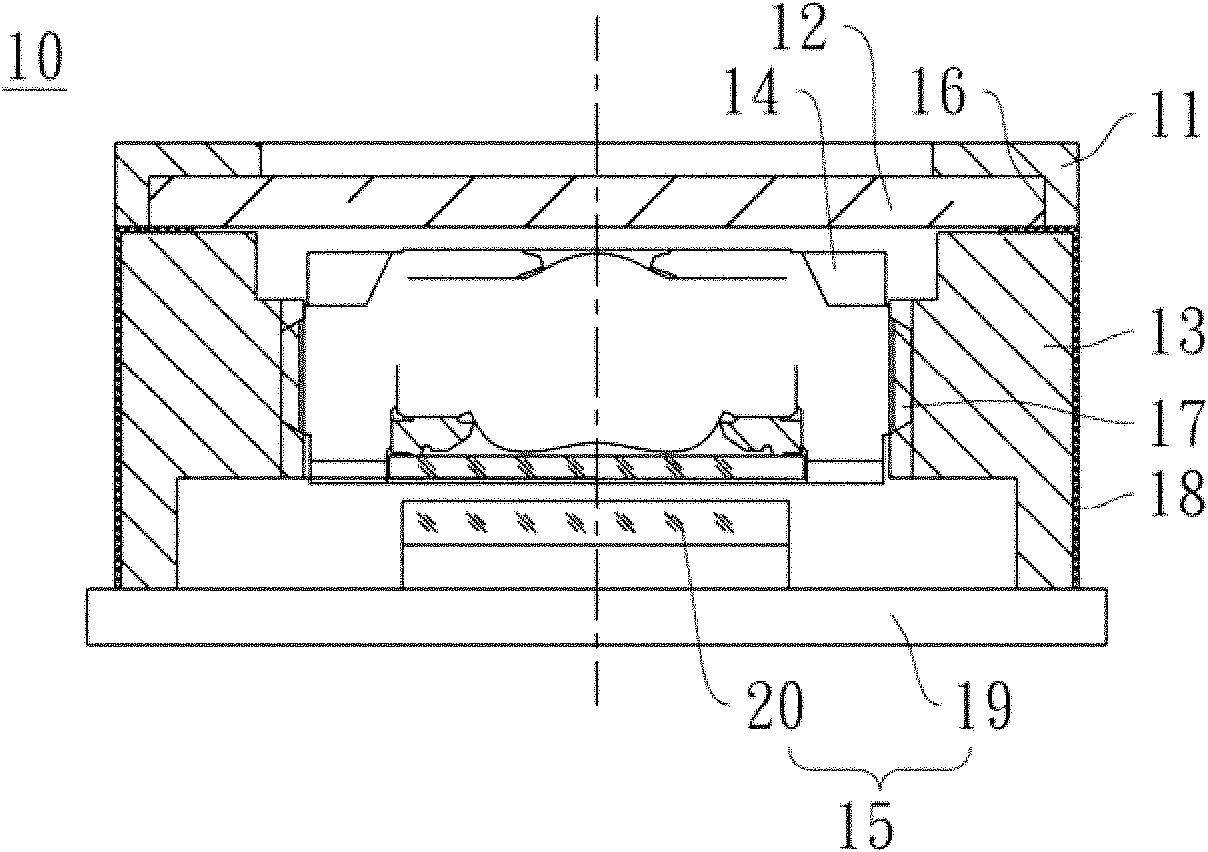

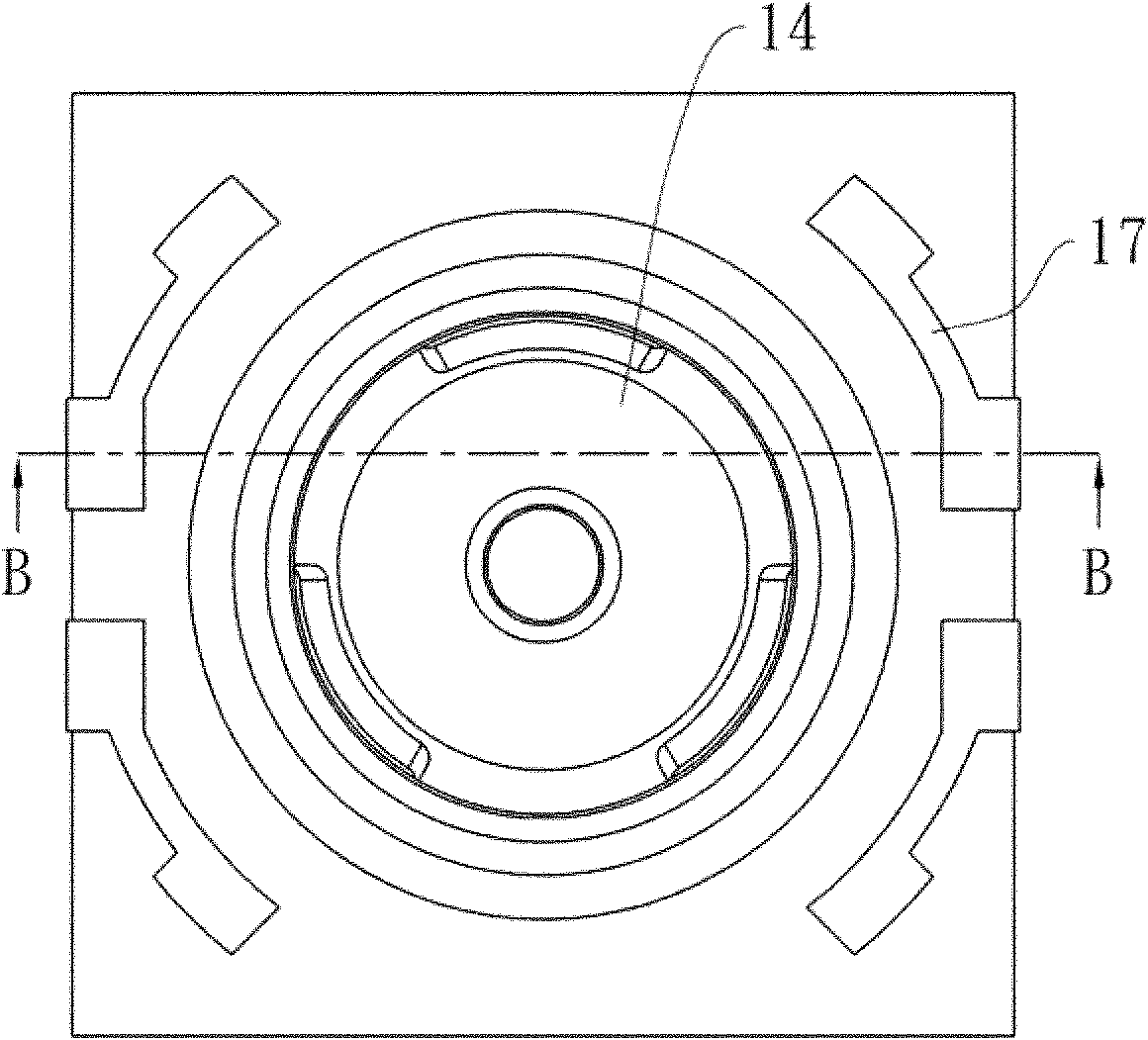

[0038] see Figure 3A and Figure 3B , respectively showing the top view schematic diagram and the first embodiment of the autofocus module of the present invention Figure 3A Schematic diagram of the section along line C-C. In this specific embodiment, the autofocus module 100 of the present invention at least includes a zoom holder 110, an electronically controlled zoom member 120, at least one power supply conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com