Bulging device for special-shaped part

A kind of parts and special-shaped technology, which is applied in the field of special-shaped parts expansion device, can solve the problems of round parts expansion, quality assurance, and low efficiency, and achieve good precision, convenient clamping and positioning, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

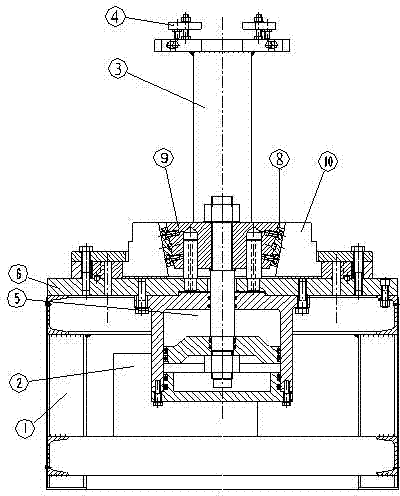

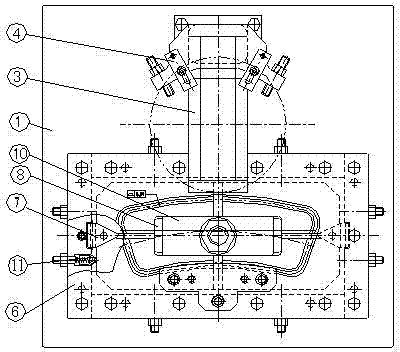

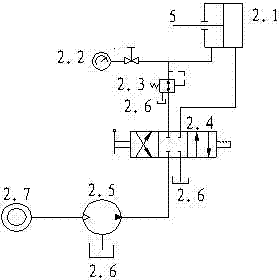

[0018] Special-shaped part expansion device, its structure is as follows figure 1 As shown, it includes a frame 1, a workbench 6, a feeding mechanism—hydraulic system 2, a positioning and clamping mechanism 4, the workbench 6 is fixed on the frame 1, and the positioning and clamping mechanism 4 is fixed on the workbench 4 through the bracket 3. The hydraulic system 2 is installed on the frame 1 under the workbench 6. There are two expansion blocks 10 sliding horizontally on the workbench 6. The two expansion blocks 10 form an expansion block assembly. The center of the expansion block assembly has a tapered hole, and the center wedge Matching, the center wedge is contained in the output shaft of the feeding mechanism-the hydraulic system 2-on the piston rod 5. Each expansion block 10 is equipped with an expansion block guide block 7 and an expansion block reset top block 11 with a back-moving spring on the workbench 6 . Feeding mechanism—hydraulic system 2 includes actuator 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com