Tangential iso-curvature bending equipment in process for producing backing ring by utilizing steel strip

A bending processing and equal curvature technology, applied in the field of curvature bending processing equipment, can solve the problems of only 3000 rings per day, detachment, etc., to achieve the effect of convenient and fast clamping, high productivity, and reduced inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

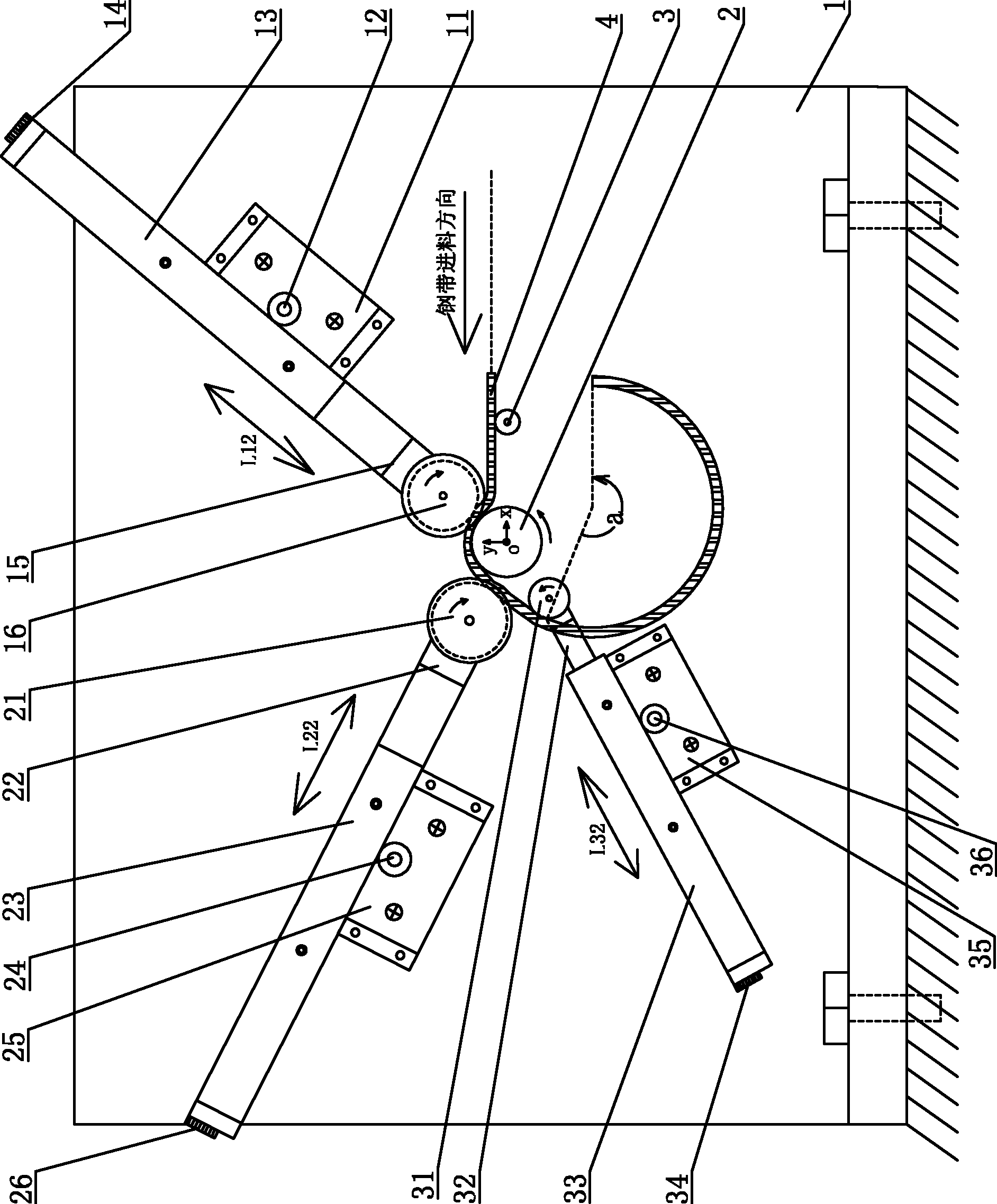

[0030] The present invention utilizes the tangential equal-curvature bending processing equipment in the process of producing lining rings from steel strips, including vertical plate base (1), pinch roller I (16), pinch roller II (21), pinch roller III (31), driven by a motor Driven round rod (2). The vertical board seat (1) is installed on a horizontal plane by a fixture. The round rod (2) is vertically installed on the vertical plate base (1) by the bearing seat, with an annular straight tooth on it. The annular straight teeth are used to drive the wound steel belt (4) to move forward. Each pinch roller is installed on the vertical plate seat (1) by the fixing mechanism in the vertical plane with its own circular side, and is respectively located at three places around the periphery of the round rod (2); the improvement of the present invention is:

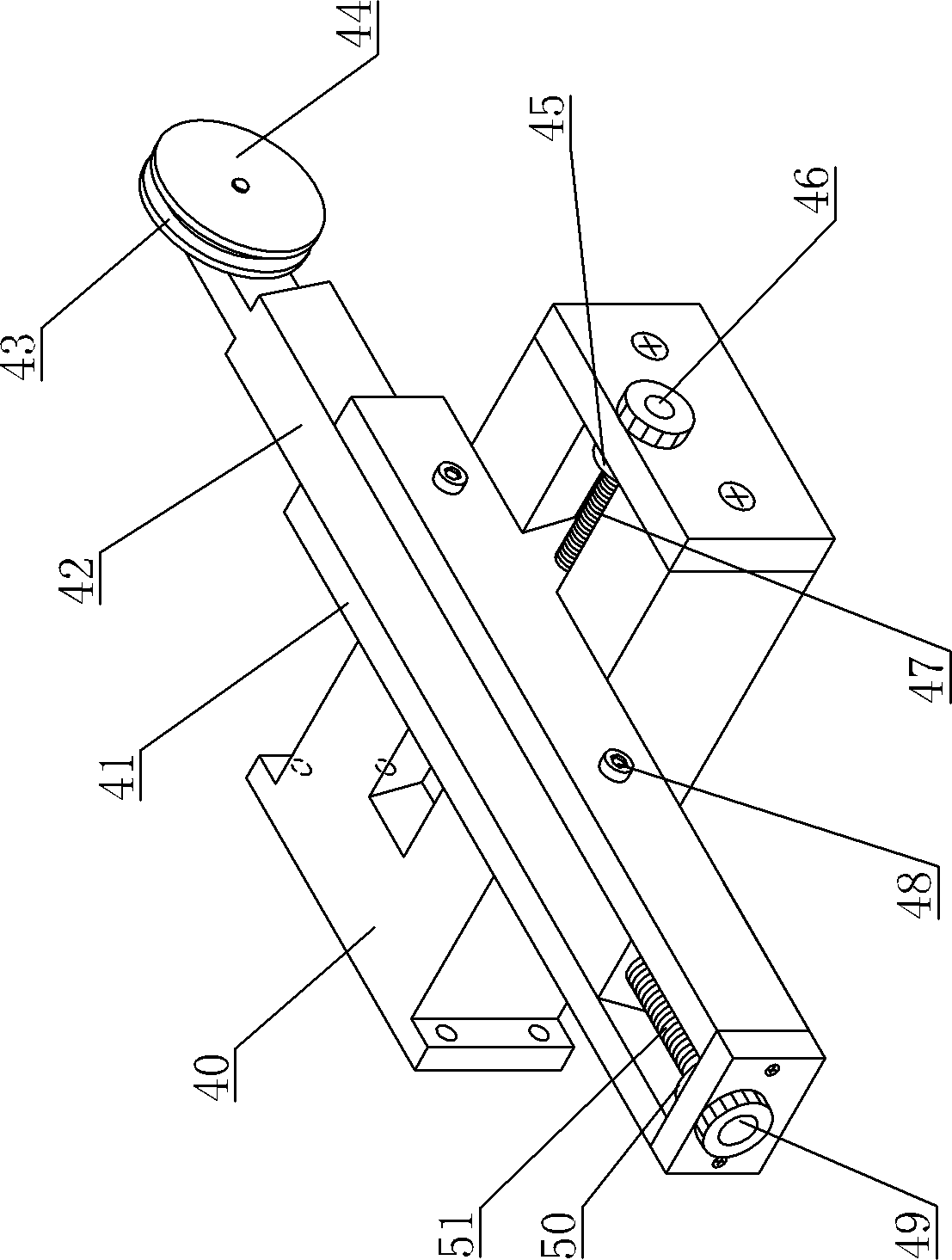

[0031] (a) The annular straight teeth on the round rod (2) are located in the annular groove around the round rod, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com