Electrochemical machining device for multi-taper inner bores

A machining device and inner hole technology, applied in the field of multi-taper inner hole electrolytic machining device, can solve the problems of large cutting area, unstable machining process, loss of tools, etc., to improve production efficiency, reduce tool consumption, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and process, the present invention will be further described.

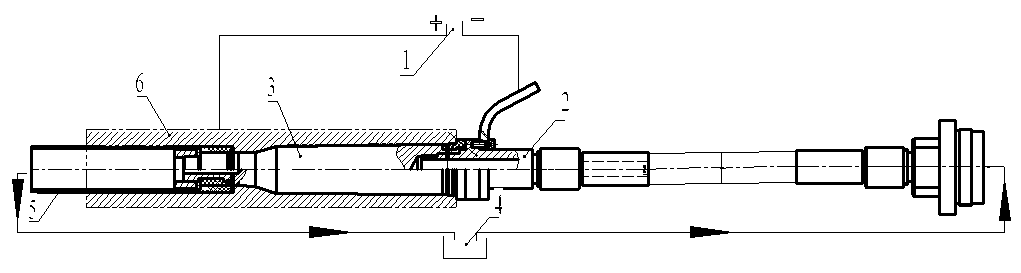

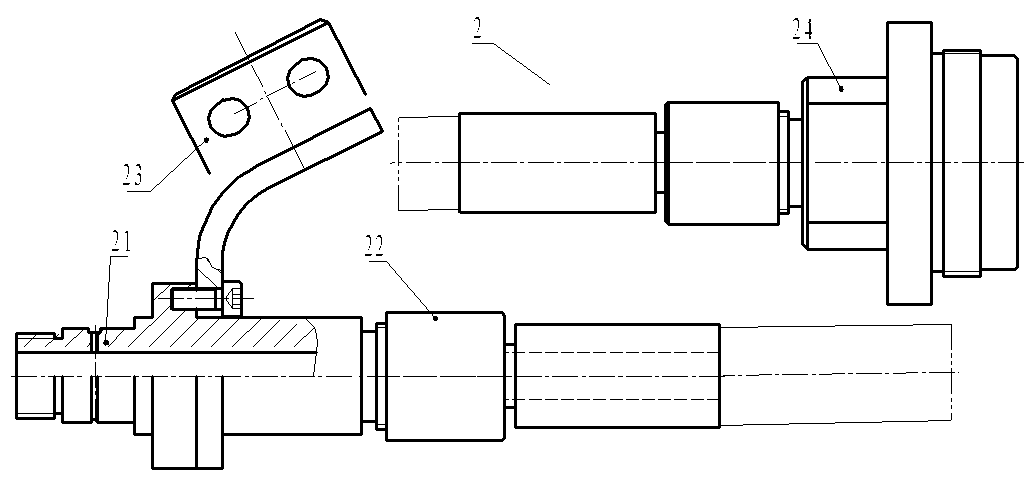

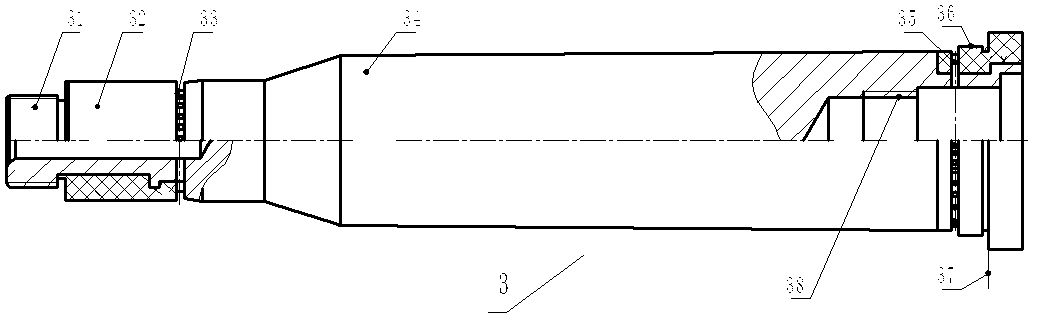

[0026] see figure 1 , figure 2 and image 3 A multi-taper inner hole electrolytic machining device shown includes a power source 1, a liquid-conducting and conductive component 2, a cathode component 3, an electrolyte system 4 and a positioning and draining component 5;

[0027] The liquid-guiding conductive assembly 2 includes a machine tool connector 24, a high-pressure liquid pipe connector 22 connected to the machine tool connector at one end, a cathode connector 21 connected to the other end of the high-pressure liquid pipe connector, and positioned on the cathode connector. The negative cable connecting row 23;

[0028] The right end of the positioning drain assembly 5 is connected to the left end of the cathode joint 21, and placed in the pre-hole of the processed member 6 together with the cathode member 3;

[0029] The electrolyte system 4 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com