Molten slag cooling device of plate-piece-type rapid cooler and molten slag rapid cooling and curing method

A rapid cooling and cooling device technology, which is applied in the field of rapid cooling and solidification of slag, and the field of slag cooling devices, can solve the problems of difficult recycling of slag and slow cooling of slag, and achieves the advantages of convenient connection and realization of recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

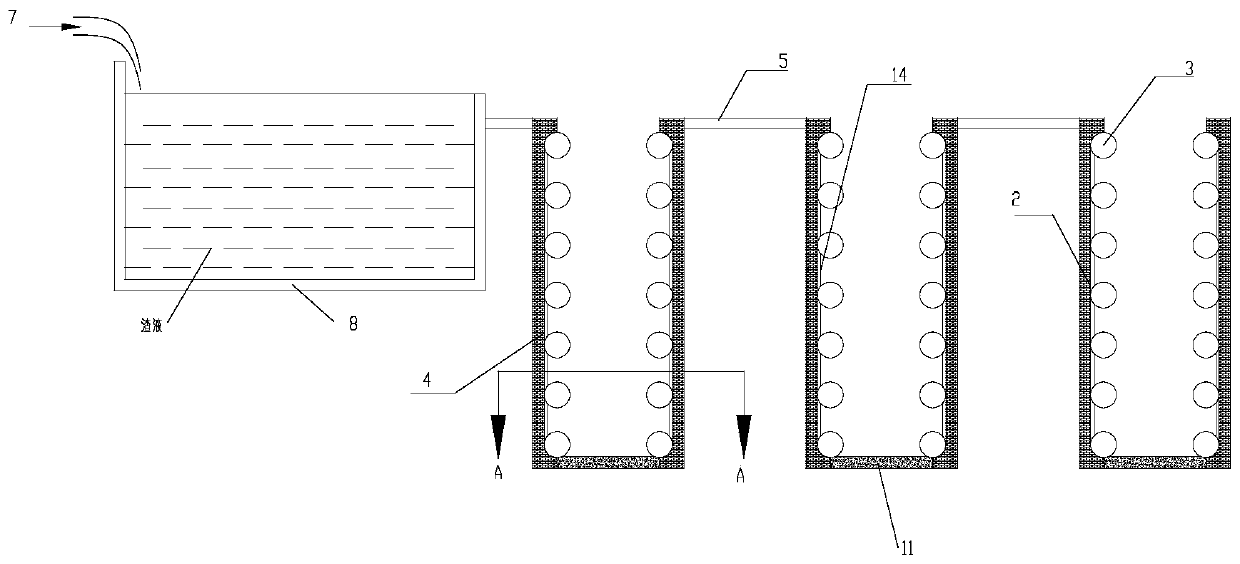

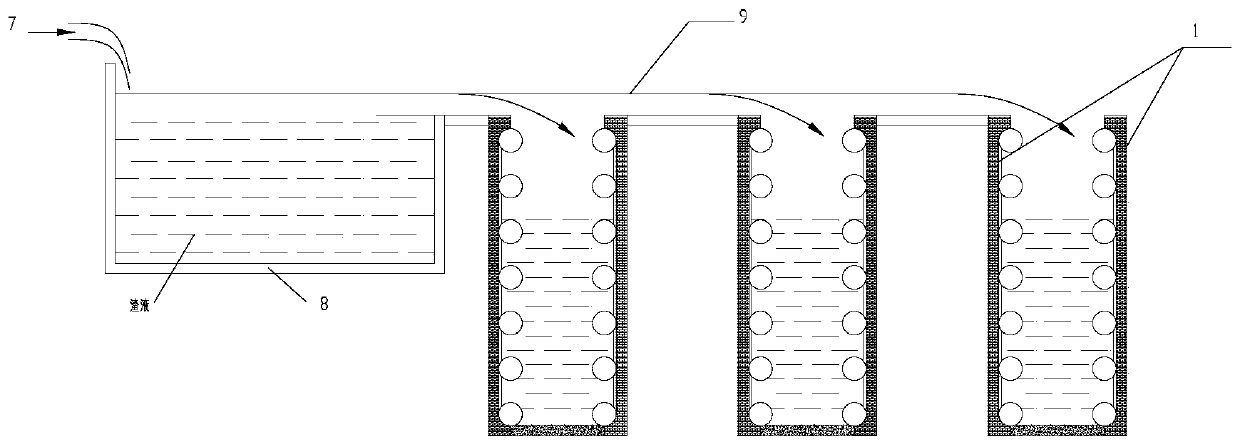

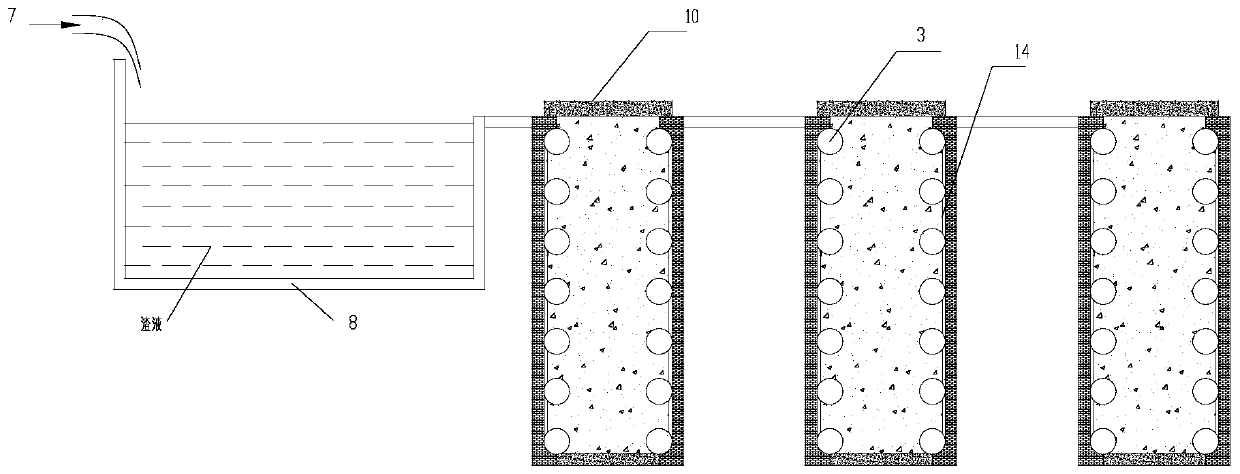

[0030] Set up a group of plate-type rapid coolers 1 as a group of three for assembly, wherein the tops of two adjacent plate-type rapid coolers 1 are connected at a certain distance through the connecting part 5; the medium conveyed by the steam drum and the circulating pump , to realize uninterrupted circulation of the steam-water mixture in the serpentine heat transfer tubes 3, wherein the 3 serpentine heat transfer tubes are connected as a whole by the connecting plate 14, and the outer surface of the serpentine heat transfer tube 3 and the inner surface of the connecting plate 14 are uniform A layer of easy-to-peel coating is provided; the first slag conveying device 7 conveys the slag to the slag pool 8, and then enters the above-mentioned group of plate-type rapid coolers 1 through the second slag conveying device 9, and passes through the plate The rapid cooling effect of the type rapid cooler 1 begins to realize rapid cooling of the slag; the slag is solidified after be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com