Machining method for double cylinder bodies of automobile air-conditioning compressor

A technology of automobile air conditioner and processing method, which is applied in the field of processing double cylinders of automobile air conditioner compressors, can solve problems such as difficulty in ensuring the parallelism and coaxiality of two processing surfaces, and piston seizure, so as to improve the output rate of feeding materials, Guaranteed positioning processing and improved coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

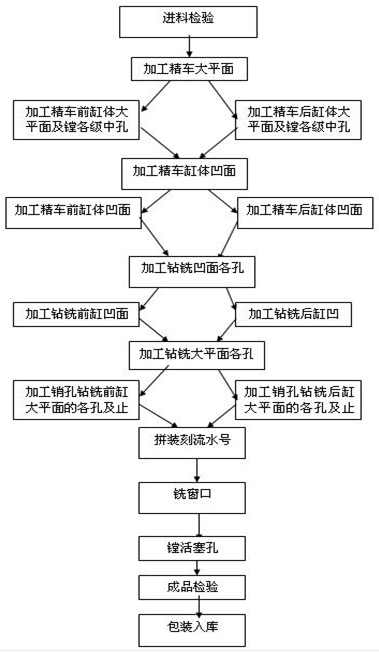

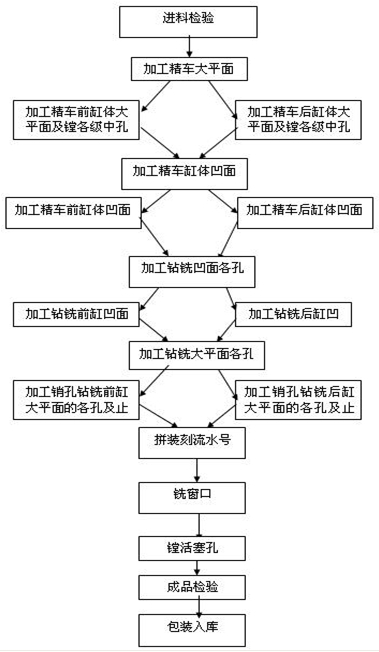

[0035] Such as figure 1 Shown, the present invention has designed a kind of processing method of automobile air-conditioning compressor double-cylinder body, is characterized in that comprising the steps:

[0036] Step (1): Inspect the front cylinder and the rear cylinder according to the product rough drawing to ensure that the machining size allowance is sufficient, the positioning size is qualified, the positioning surface is flat and there is no material shortage crack;

[0037] Step (2): Machining the large surface of the finish car and boring the middle holes at all levels on the CNC lathe, specifically including the following processes:

[0038] Step (21): On the CNC lathe, the large plane of the front cylinder body of the finish car is processed by clamping the rough piston hole and the inner cavity surface for close positioning;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com