System and method for a two piece spray nozzle

A technology for nozzles and liquid dispersion, which is used in spray devices, spray devices, liquid spray devices, etc. It can solve the problem of high debugging time and cost, and achieve the effects of low head loss, uniform particle size, and improved concentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

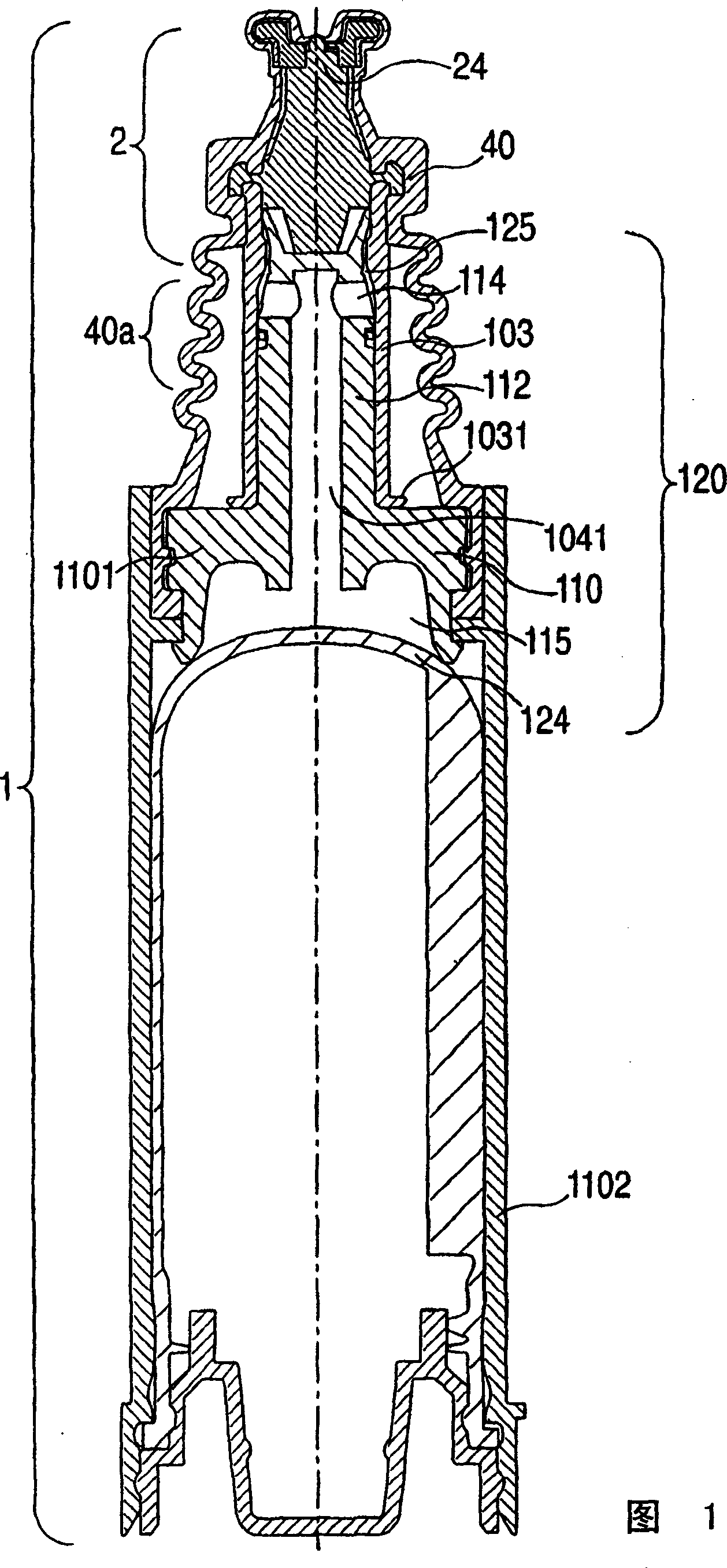

[0029] An aerosol nebulizer system 1 comprising a first exemplary embodiment of an aerosol top mechanism 2 according to the present invention is shown in FIG. 1 . As shown in FIG. 1 , a first exemplary embodiment of an aerosol top 2 according to the present invention has a substantially tubular body 103 and a substantially tubular portion 112 extending inwardly and along the body 103 . Pistons 110 are connected. The body 103 includes a lower base portion 1031 extending radially beyond the lower end of the body 103 in a flange-like configuration, which rests against the piston shoulder 1101 when the pump is in the rest position. superior. The flexible housing 40 covers the aerosol top mechanism 2 and the body 103 . The tubular portion of the piston contains a hollow axial internal passage 1041 which communicates fluid to the body 103 through radial passages 114 on either side of the internal passage 1041 when the pump is in the load or "ready" position.

[0030] As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com