Urea plant and method for cleaning associated gas stream

A urea device and gas flow technology, applied in the field of gas flow systems, can solve problems such as poor distribution of gas flow, difficulty in controlling formation, and reduced efficiency, and achieve the effects of low head loss, small size, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

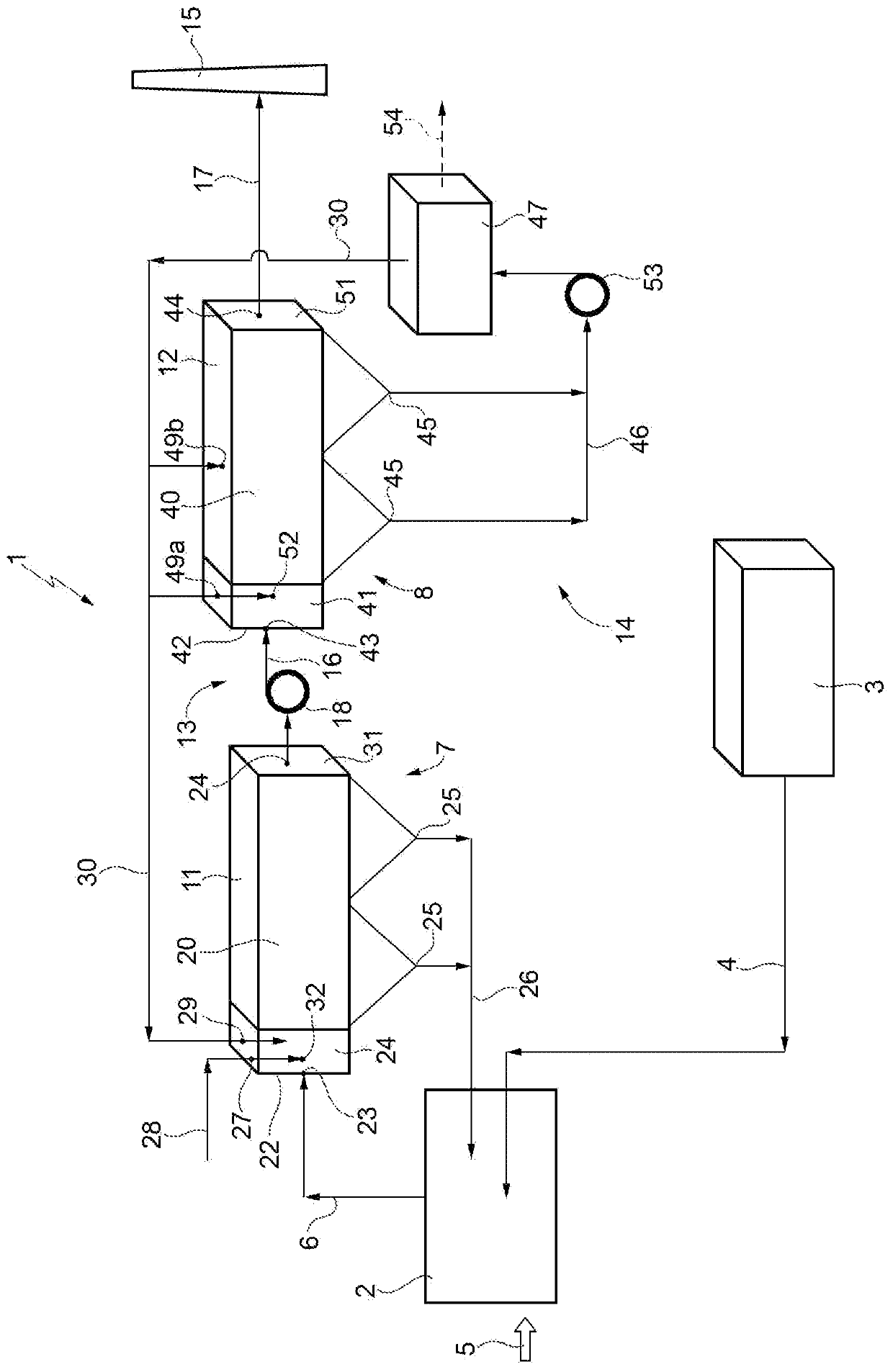

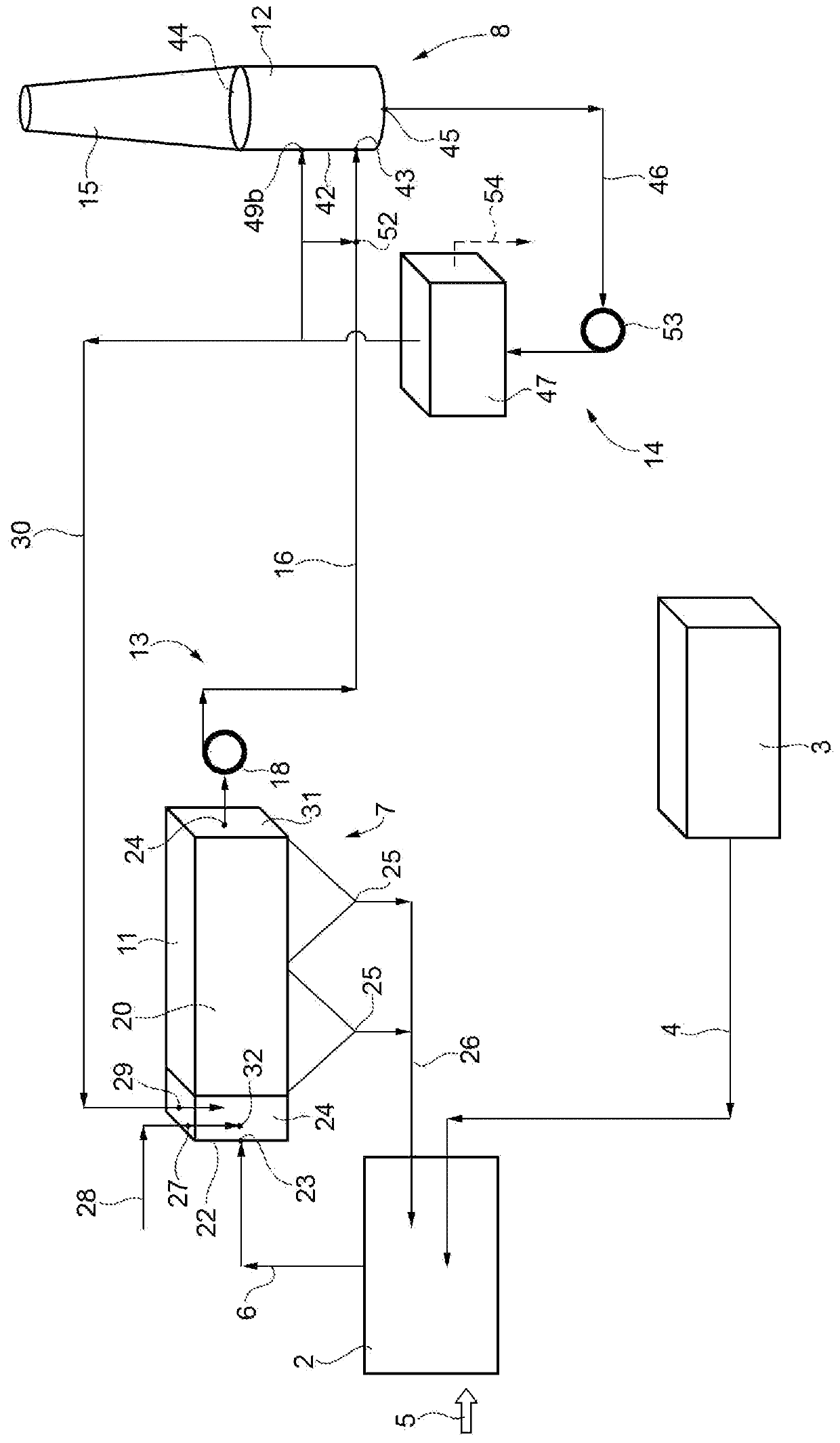

[0034] figure 1 A cleaning system 1 is schematically shown for treating a gas stream leaving a coagulation unit 2 of a urea plant 3 , in particular for removing urea powder and gaseous ammonia from said gas stream.

[0035] The urea plant 3 is basically known per se and will therefore not be described or illustrated in detail. In general, the urea plant 3 comprises: a urea synthesis reactor, in which the urea synthesis reaction from ammonia and carbon dioxide takes place; The resulting urea solution is gradually concentrated, removing water and unreacted ammonia and carbon dioxide, and recirculating the recovered components; and a vacuum section, which is equipped with a vacuum system and connected to the waste water treatment section.

[0036] The urea plant 3 is connected to the solidification unit 2 via the urea supply line 4, the solidification unit comprises, for example, a granulator or a prilling tower, and the molten urea produced in the urea plant 3 is transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com