Cutting machining method for rectangular rubber rings

A cutting and rectangular technology, applied in metal processing and other directions, can solve the problems of large fluctuation of cutting size, inclined cutting surface, and inability of nylon lining to fit tightly, so as to achieve the effect of improving cutting dimensional accuracy and improving dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

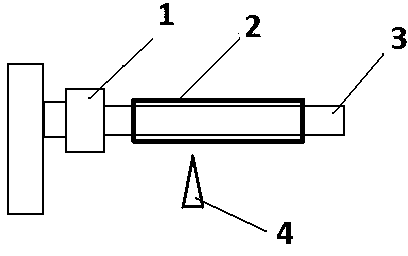

[0042] In the present embodiment, using the method of the present invention, the rectangular rubber cylinder 2 with a wall thickness of 1.9 mm and external dimensions of 213 mm in length, 64 mm in width and 45 mm in height is cut and processed into 8 rubber rectangular rings with a height of 5 mm. The steps are as follows:

[0043] 1) Process the rectangular rubber cylinder 2;

[0044] 2) Turn the rectangular rubber tube 2 over so that the inner wall becomes the outer wall;

[0045] 3) Put the inverted rectangular rubber tube 2 on the circular nylon inner liner 3 with an outer diameter of 188mm;

[0046] 4) Clamp the nylon lining 3 onto the lathe;

[0047] 5) start the lathe to make the nylon lining 3 with the rectangular rubber tube 2 rotate at a speed of 2500 rev / min;

[0048] 6) The moving blade 4 cuts the rectangular rubber tube 2 into 8 rectangular rubber circles.

[0049] Thereby the size of processing is wall thickness: 1.9mm, external dimension is: length 213mm, wid...

Embodiment 2

[0051] The difference between embodiment 2 and embodiment 1 is that the outer diameter of the circular nylon lining 3 in embodiment 2 is 185.2mm, and the stretching amount of the circumferential direction of the rectangular rubber tube 2 is 5% at this moment; The cutting equipment is a cutting machine.

Embodiment 3

[0053] The difference between Example 3 and Example 1 is that the outer diameter of the circular nylon lining 3 in Example 3 is 194 mm, and the stretching amount of the rectangular rubber tube 2 in the circumferential direction is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com