Method for asymmetrically dismantling cable-stayed bridge

An asymmetric, cable-stayed bridge technology, applied in building maintenance, construction, building construction, etc., can solve the problems of long construction period, poor effect, influence, etc., and achieve the improvement of safety factor, reduction of construction links, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

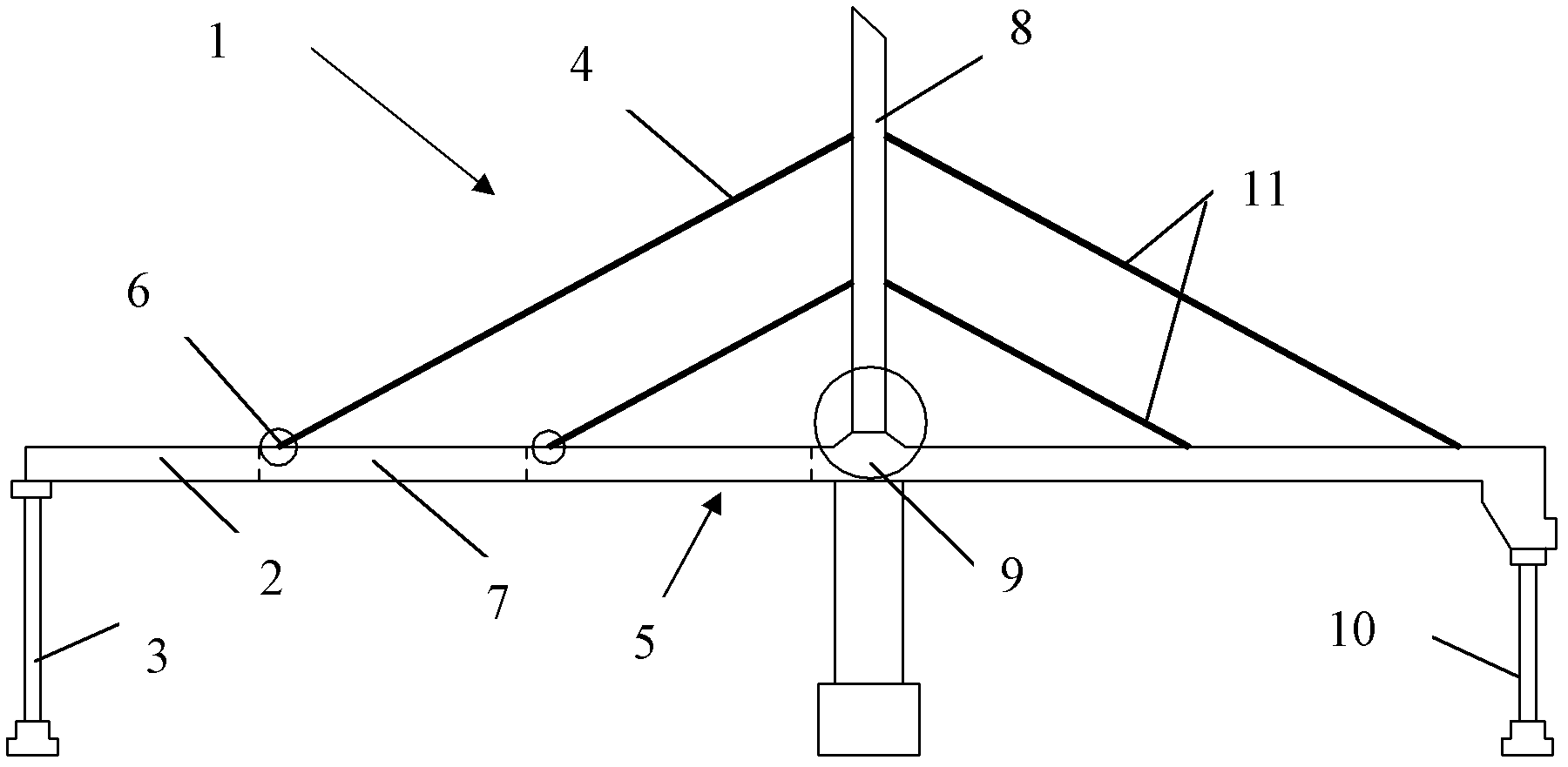

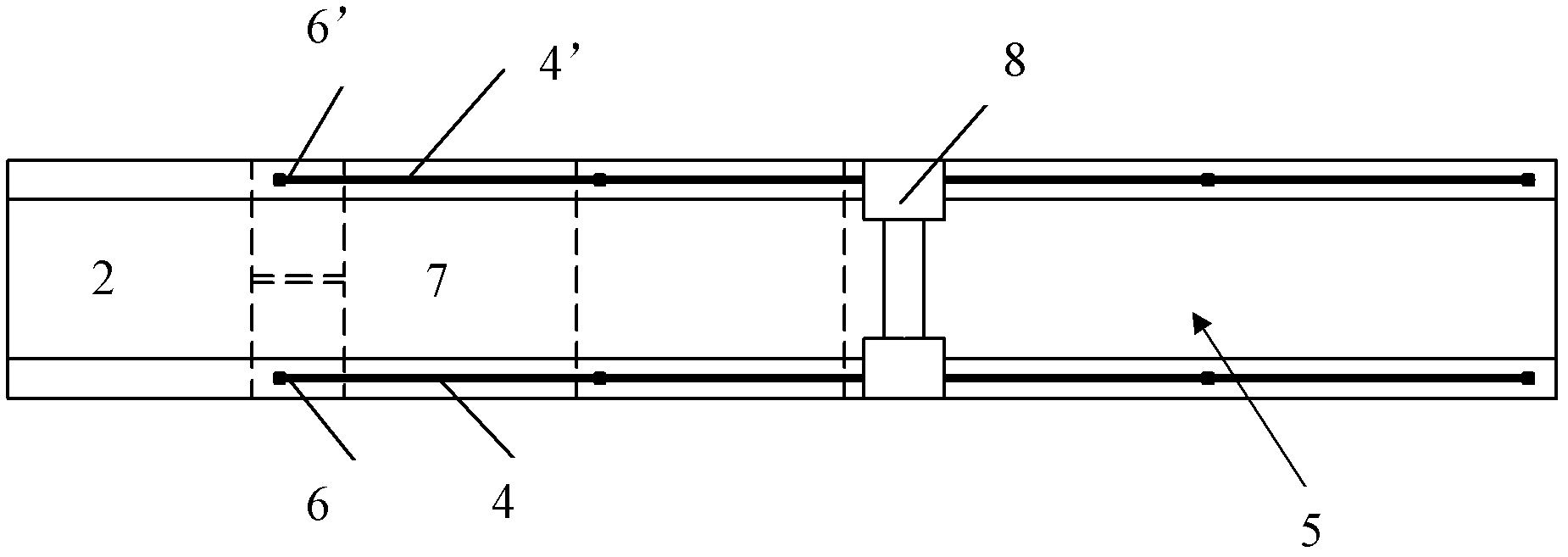

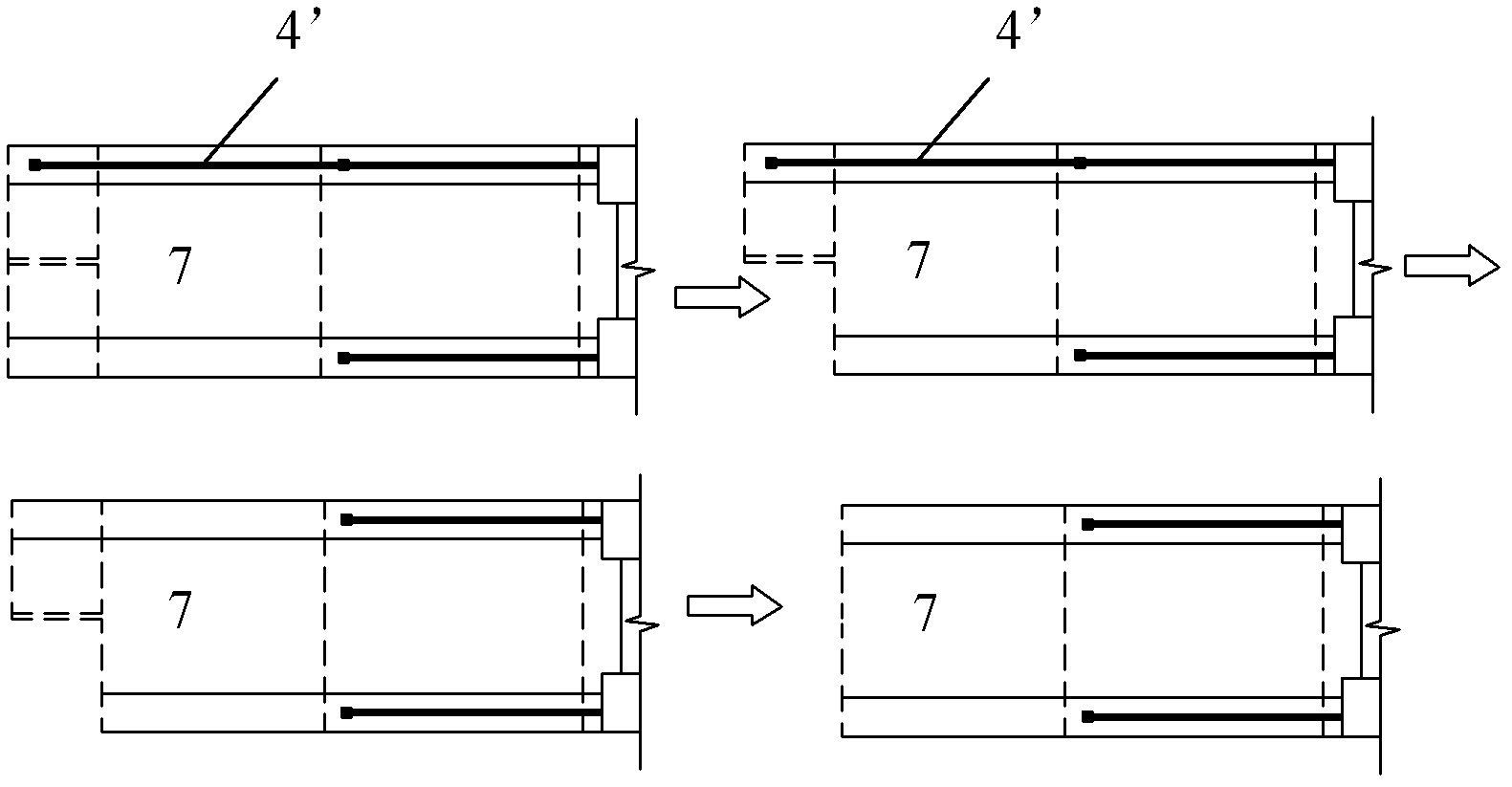

[0017] The method for dismantling the asymmetrical cable-stayed bridge provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Such as Figure 1-Figure 4 Shown, the method for dismantling the asymmetrical cable-stayed bridge provided by the present invention comprises the following steps carried out in order:

[0019] 1) First, the connection between the first main girder section 2 located at the outermost side of one end of the cable-stayed bridge 1 and the pier 3 connected to it is removed. 4' and the anchor point 6 of the main beam 5 are in a cantilever state; according to the analysis of the calculation results of the maximum flexural bearing capacity of the main beam 5 at the anchor point 6, the maximum flexural bearing capacity of this section is greater than that of the first beam during the demolition process. The maximum cantilever bending moment generated by a main beam sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com