Centralized lubrication mechanism for excavator working device

A working device and centralized lubrication technology, which is applied in the field of dry oil lubrication device and the centralized lubrication device of the hinged surface of the excavator working device, which can solve the problem of low efficiency of lubricating oil filling, inability to centrally add lubricating oil and lubricating oil. Inconvenience and other problems, to achieve the effect of improving work efficiency, shortening filling time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

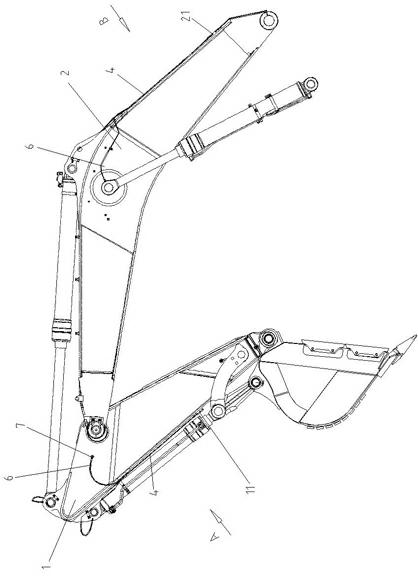

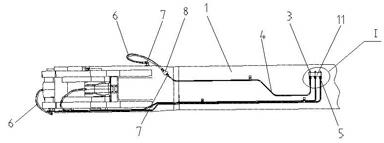

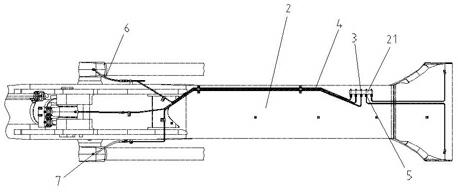

[0014] This example Figure 1 ~ Figure 3 As shown, it includes a first lubricating oil nipple integrated block 11 arranged in the lower end of the arm 1 , a second lubricating oil nipple integrated block 21 arranged in the lower end of the boom 2 , a plurality of lubricating oil nipples 3 , and a plurality of oil guide pipes 4 . Such as figure 2 As shown, three lubricating oil nipples 3 are fixed side by side on one side of the first lubricating oil nipple integrated block 11, and the other side of the first lubricating oil nipple integrated block 11 is respectively connected to one end of three oil guide pipes 4 through three oil pipe joints 5, 3 The other end of the root oil guide pipe 4 leads to the articulation surfaces of the corresponding joints of the arm oil cylinder and the boom oil cylinder through the flexible pipe 6 and the flexible pipe joint 7 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com