Measuring system of swing angle of swing nozzle and measuring method of swing angle

A technology of swing angle and measurement method, applied in the direction of measurement device, measurement angle, mapping and navigation, etc., can solve the problem that the nozzle cannot use tooling equipment and contact sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

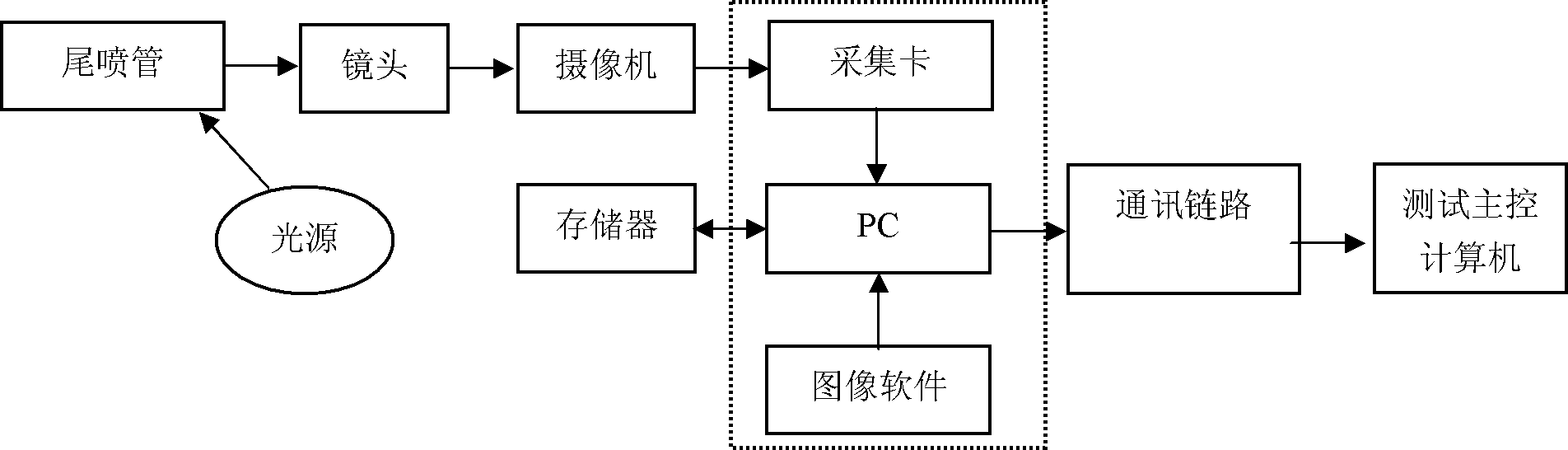

[0022] Embodiment one: the measurement system of the swing angle of the swing nozzle described in this embodiment includes an image acquisition device and an image processing computer, the image acquisition device is used to continuously collect the image information of the tail nozzle to be measured, and collect The received image information is sent to an image processing computer, and the image processing computer is used to process the received image information, and obtain the swing angle information of the tail nozzle to be tested according to the continuously collected image information.

[0023] The image acquisition device is generally fixed by a tripod, so that the lens direction of the image acquisition device can be adjusted in any direction with any degree of freedom in three-dimensional space.

[0024] The image resolution of the image acquisition device in this embodiment is not lower than 1024×1024, and the image acquisition rate is not lower than 50 fps.

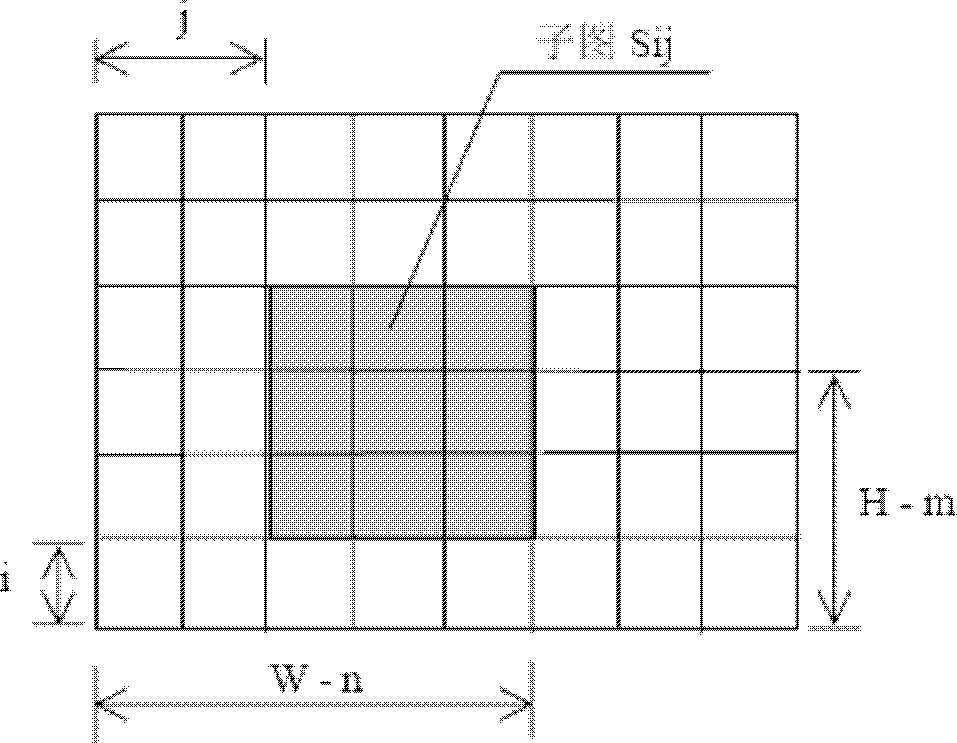

[00...

specific Embodiment approach 2

[0038] Specific embodiment 2: This embodiment is to further limit the image acquisition device in the measurement system for the swing angle of the oscillating nozzle described in the specific embodiment 1. The image acquisition device described in this embodiment consists of an auxiliary light source and Composed of camera equipment, the camera equipment is realized by an image acquisition device with a high-speed image transmission interface, and the camera equipment is connected with an image processing computer through the high-speed image transmission interface; the auxiliary light source is used to irradiate the tail nozzle to be tested, Provide auxiliary light source for camera equipment.

[0039] Since the field of view of the nozzle is relatively large and the speed of the nozzle is relatively high, the brightness in the field of view has a great influence on the image quality when taking pictures. Therefore, it is necessary to supplement light to the field of view of ...

specific Embodiment approach 3

[0054] Specific Embodiment 3. The description in this embodiment is the description of the measurement process of the swing angle by using the swing angle measurement system of the swing nozzle according to the present invention.

[0055] The measurement process described in this embodiment is:

[0056] First perform the step of calibrating the measuring system, and then start the step of measuring the swing angle of the tail nozzle, which is executed cyclically in the following two steps:

[0057] The step of collecting the image of tail nozzle;

[0058] A step of calculating and obtaining the swing angle of the tail nozzle to be tested at the moment according to the collected images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com