Automatic testing device of make-and-break of superconducting coil quench protection signal transmission line in fusion device

A technology of signal transmission line and superconducting coil, applied in the direction of fault location, etc., can solve the problems of delaying the experiment process, affecting the stable operation of the quench protection system, etc., to achieve the effect of improving work efficiency, friendly interface and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

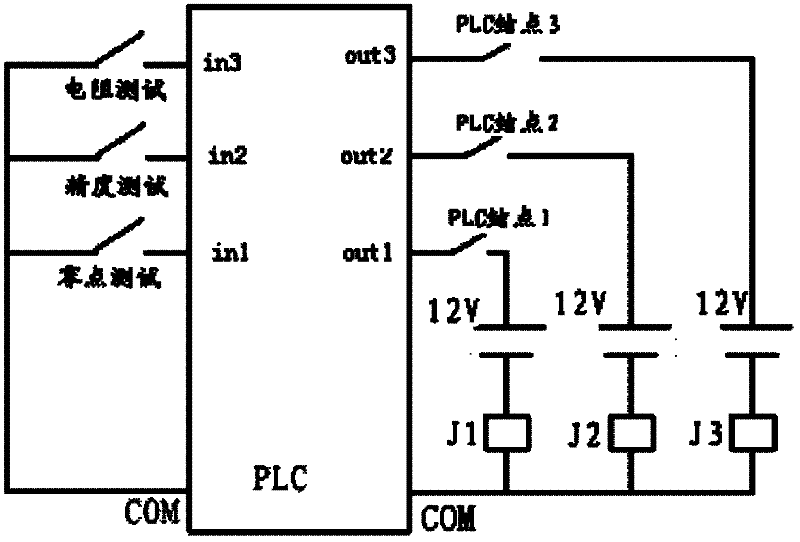

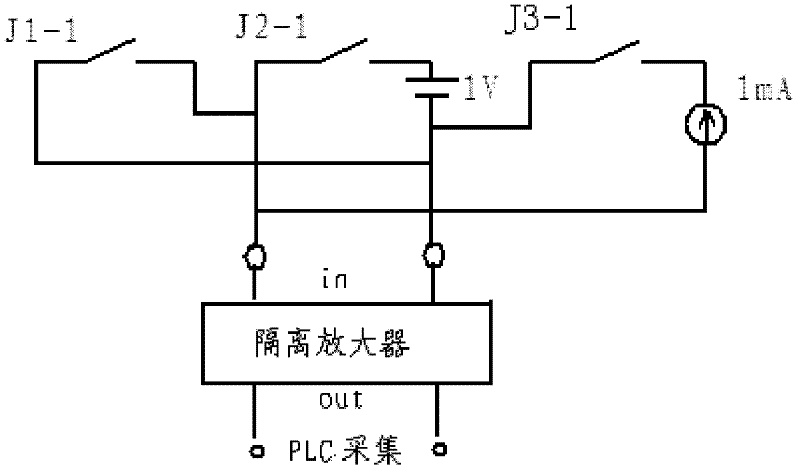

[0015] The automatic test device for the on-off of the superconducting coil quench protection signal transmission line in the fusion device includes a main control device PLC and an isolation amplifier. The main control device PLC includes an analog input module, three input terminals and their corresponding Three output terminals, the three input terminals are respectively connected with a switch, the other end of the three switches is connected to the common terminal COM of the main control device PLC, and the three output terminals are respectively connected in series with PLC nodes, DC power supply block and relay, the relays are J1, J2, J3 respectively, the other ends of the relays J1, J2, J3 are connected to the common terminal COM of the main control device PLC; the relays J1, J2, J3 respectively include a Normally open terminals J1-1, J2-1, J3-1, the J1-1 is connected in parallel with the isolation amplifier, the J2-1 is connected in parallel with the isolation amplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com