Parallel multi-winding motor

A multi-winding and winding technology, which is applied to the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problems of system inoperability, reduced reliability, and low reliability, so as to improve reliability and reliability. The effect of high performance, reliability and continuous operation ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be further described below in conjunction with the drawings, but the scope of the actual protection structure of the present invention is not limited to the embodiments shown in the drawings.

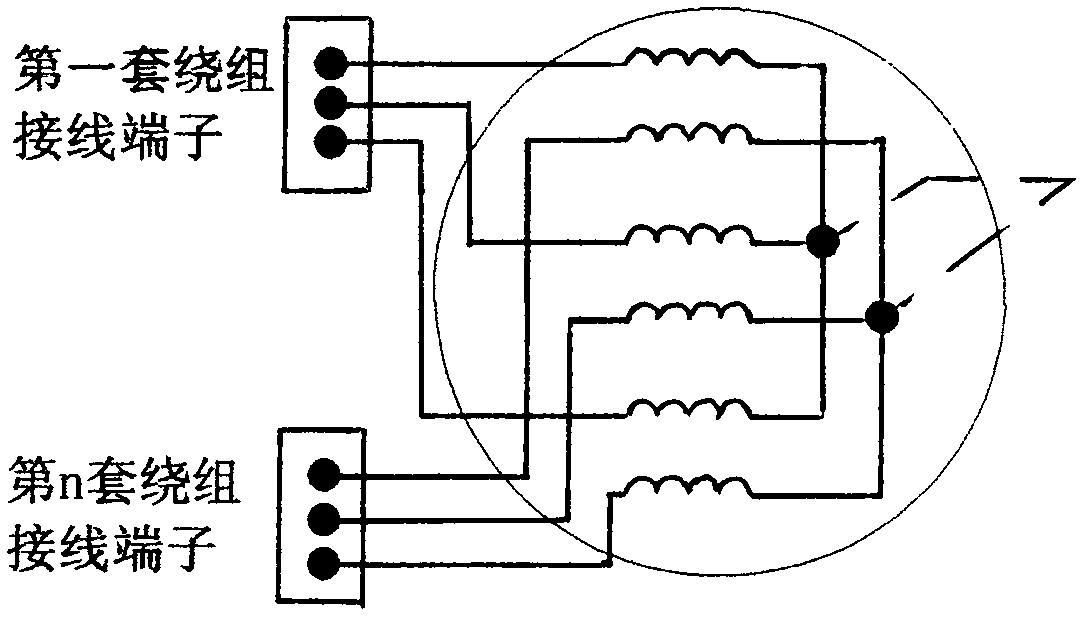

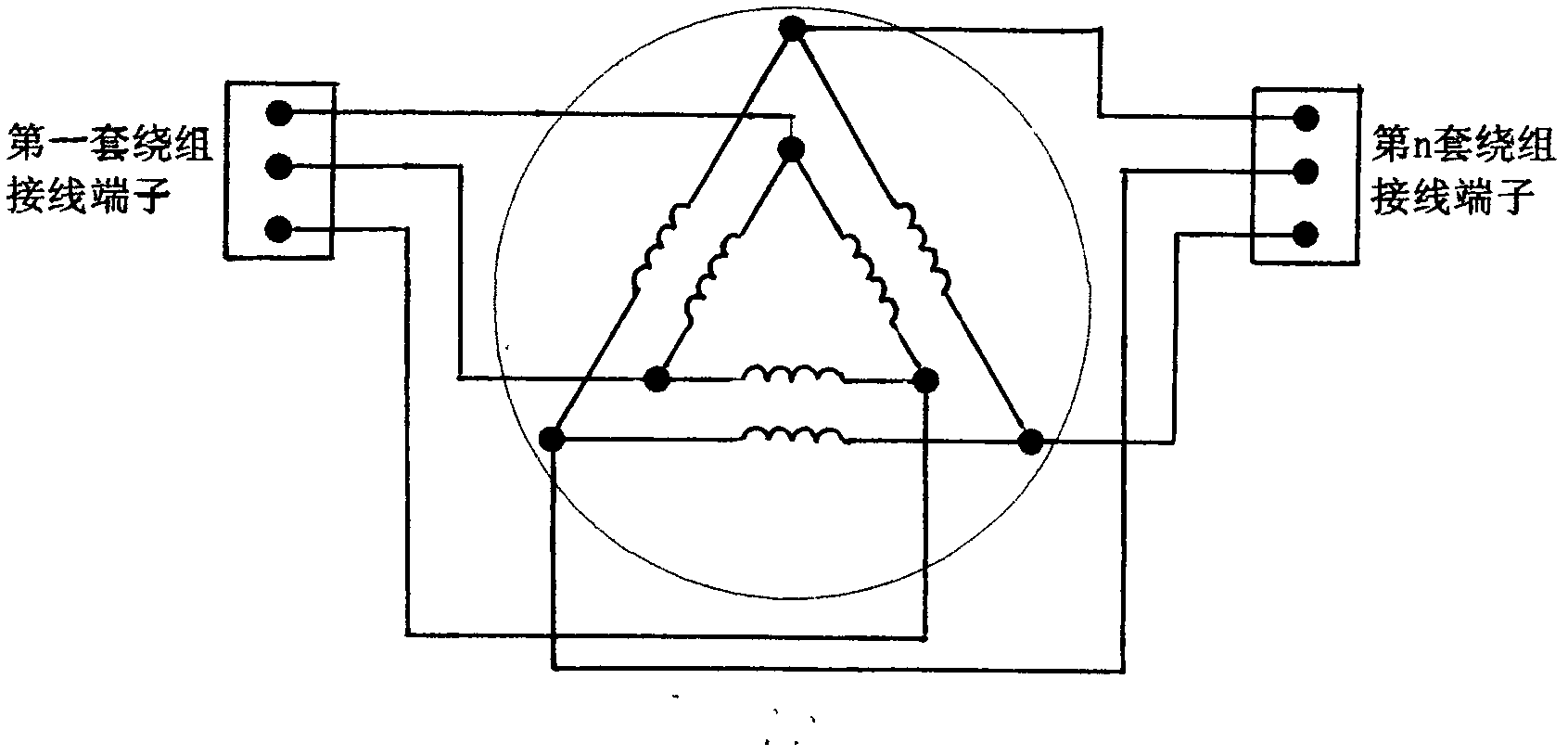

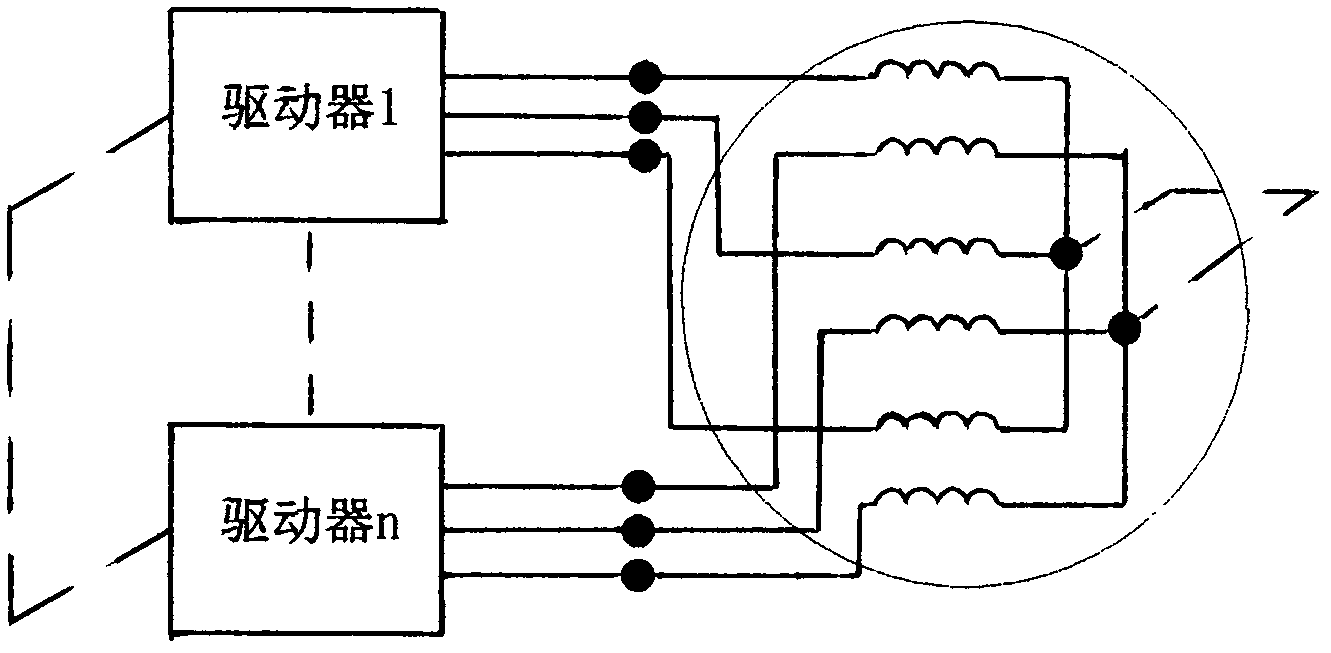

[0014] Referring to the accompanying drawings, except for the stator winding, the structure of the motor of the present invention, such as the rotor and the base, is the same as that of various traditional three-phase AC motors. The difference is that the stator winding of the traditional motor is composed of a set of windings, while this The inventive motor winding is composed of not less than two sets of functional windings in parallel. In terms of setting structure, the connection method of each set of functional windings in the present invention is similar to that of traditional motor windings (such as Y-type, △-type windings, etc.), and each set of functional windings is in phase and parallel relationship. When each set of functional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com