Access network and indoor wiring optical cable

An indoor wiring and access network technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of high construction and maintenance costs of optical cables, poor mechanical and temperature performance, and heavy access network optical cables, so as to achieve good anti-rodent effect and reduce construction costs. Difficulty and cost, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

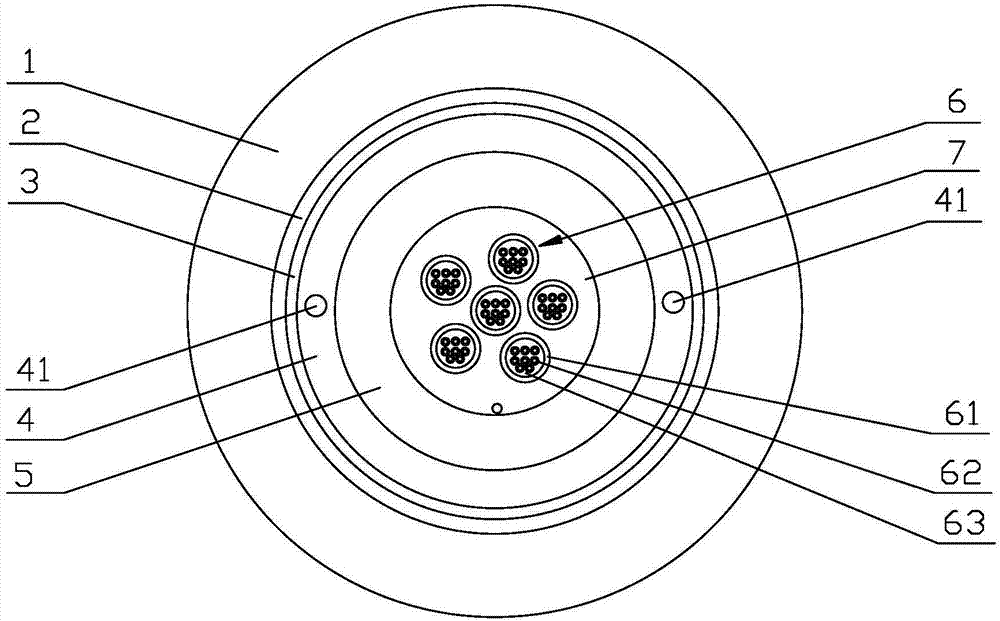

[0026] see figure 1 As shown, the embodiment of the present invention provides an access network and an indoor wiring cable. The access network and the indoor wiring cable sequentially include an outer sheath 1, an aluminum strip 2, a water blocking strip 3, a strengthening element 4, and an inner sheath from outside to inside. Set of 5 and cable core.

[0027] The outer sheath 1 is made of polyethylene, low-smoke halogen-free flame-retardant polyolefin or polyvinyl chloride. The outer sheath 1 is tightly wrapped on the aluminum strip 2, and the aluminum strip 2 and the water blocking strip 3 are arranged along the length direction of the optical cable.

[0028] The strengthening element 4 is provided with two tearing ropes 41 arranged along the length direction of the optical cable, the strengthening element 4 is made of aramid yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com