42-(Dimethylphosphono)rapamycin solid composition and coating method thereof

A technology of dimethyl phosphinoylidene and solid composition, applied in the field of solid pharmaceutical composition and its coating, can solve the problems of poor stability, low in vitro dissolution rate, poor solubility, etc., achieve good stability and improve solubility , the effect of better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

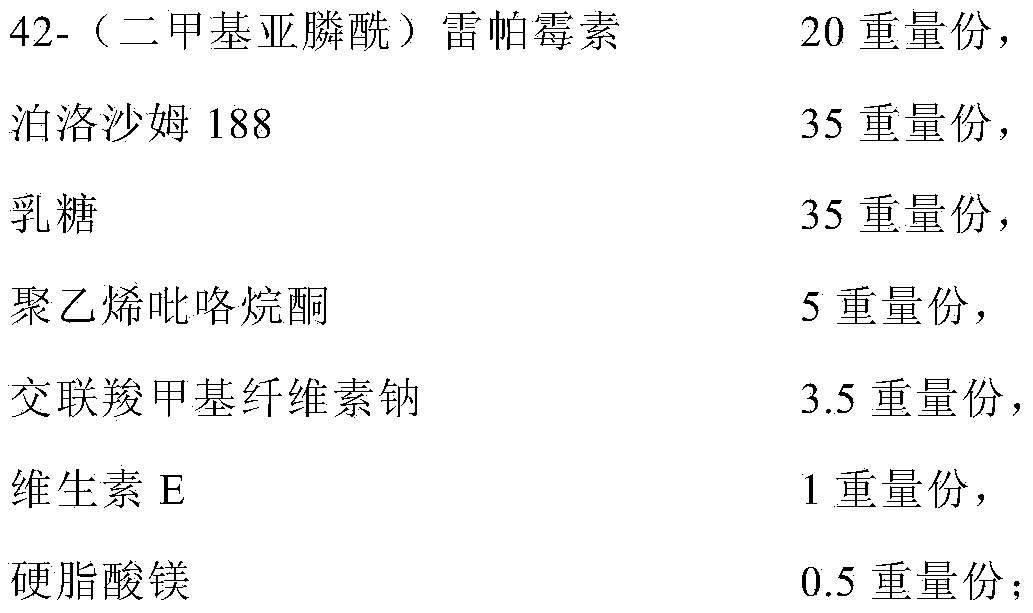

[0040] Table 1

[0041] Category

[0042] Prepare each material according to Table 1, pass the starch, dextrin, and crospovidone through an 80-mesh sieve. Weigh the starch, dextrin, and crospovidone in a mixer according to the ratio shown in Table 1. Standby; Dissolve AP23573, poloxamer 188, ascorbyl palmitate, and starch slurry in 90% ethanol to obtain a mixed solution, and then add the mixed solution to the mixer containing the above-mentioned starch, dextrin and crospovidone Stir and mix to form a soft material. Then, the soft material is granulated with a 18-mesh granulating machine to obtain AP23573 wet granules. Then the AP23573 wet granules are dried in a drying oven or a fluidized bed dryer at 45-60℃, and then Use a 20-mesh sieve granulator to sizing to obtain AP23573 dry particles. Finally, AP23573 dry particles and micro-powder silica gel are mixed in a mixer to obtain AP23573 solid composition.

Embodiment 2

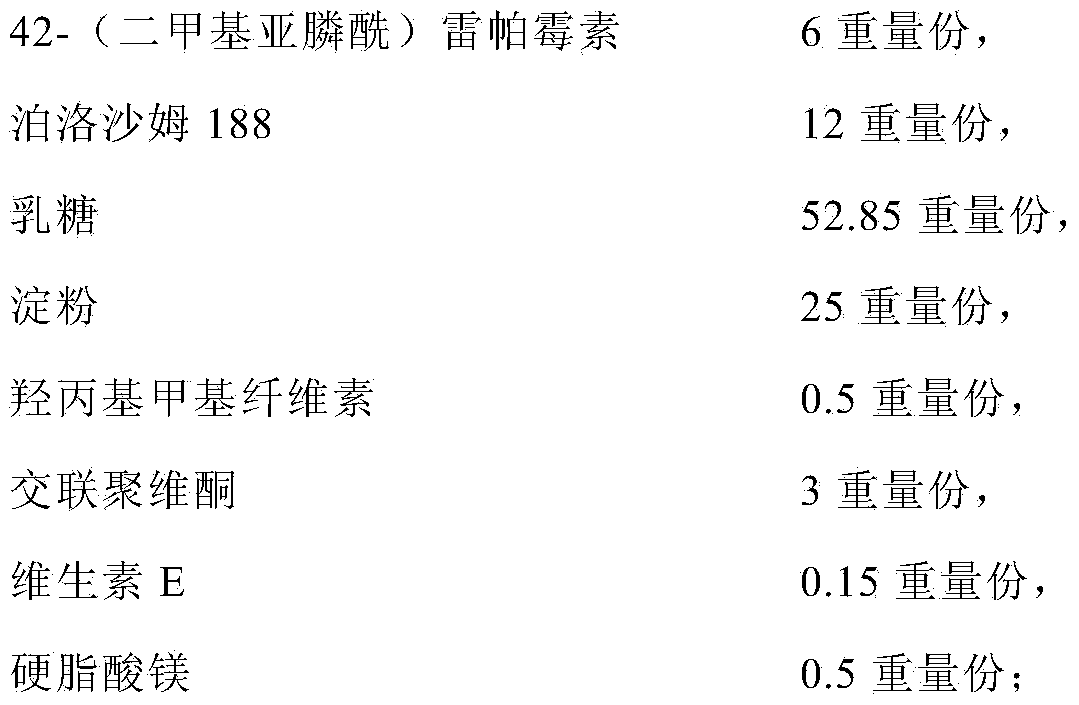

[0044] Table 2

[0045] Category

[0046] Prepare the materials according to Table 2. Pass the microcrystalline cellulose and sodium carboxymethyl starch through an 80 mesh sieve. Weigh the microcrystalline cellulose and sodium carboxymethyl starch in a mixer according to the ratio shown in Table 2. Standby; Dissolve AP23573, polyvinylpyrrolidone, and butylated hydroxytoluene in 95% ethanol to obtain a mixed solution, then add the mixed solution to a mixer containing the above-mentioned microcrystalline cellulose and sodium carboxymethyl starch, stir and mix to form The soft material is then granulated with a 18-mesh granulating machine to obtain AP23573 wet granules, and then the AP23573 wet granules are dried in a 45-60℃ drying oven or a fluidized bed dryer, and then sieved with 20 mesh The granulator granules the granules to obtain AP23573 dry granules. Finally, the AP23573 dry granules and the micro-powder silica gel are mixed in a mixer to obtain an AP23573 solid composit...

Embodiment 3

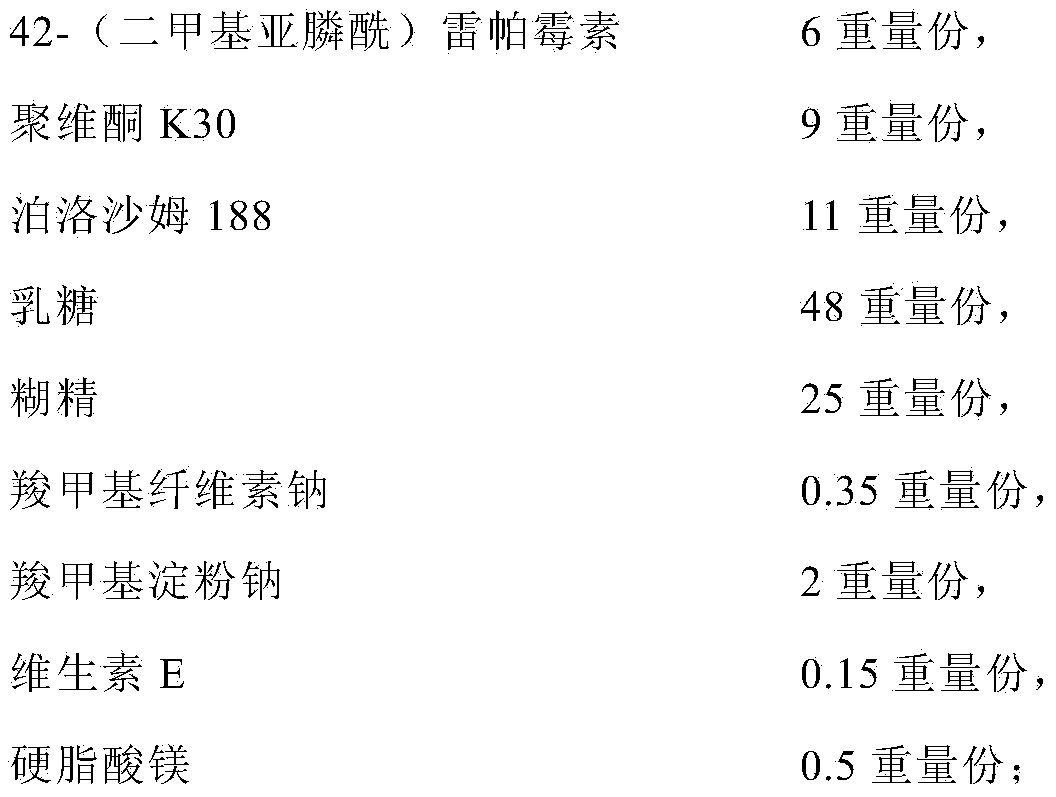

[0048] table 3

[0049] Category

[0050] Prepare each material according to Table 3, pass the lactose and hydroxypropyl cellulose through an 80-mesh sieve, weigh the lactose and hydroxypropyl cellulose according to the ratio shown in Table 3, and mix them in a mixer for use; Propyl methyl cellulose, sodium carboxymethyl cellulose, and vitamin E are dissolved in 95% ethanol to obtain a mixed liquid, and then the mixed liquid is added to the mixer containing the above lactose and hydroxypropyl cellulose to stir and mix. The soft material is formed, and then the soft material is granulated with a 18-mesh granulating machine to obtain AP23573 wet granules, and then the AP23573 wet granules are dried in a drying oven at 45-60°C or a fluidized bed dryer, and then sieved with 20 mesh The granulator is sized to obtain AP23573 dry granules. Finally, AP23573 dry granules and magnesium stearate are mixed in a mixer to obtain AP23573 solid composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com