Gluing device

A technology of applying rubber rollers and rubber discs, which is applied to the device for coating liquid on the surface, coating, etc., and can solve problems such as uneven glue layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

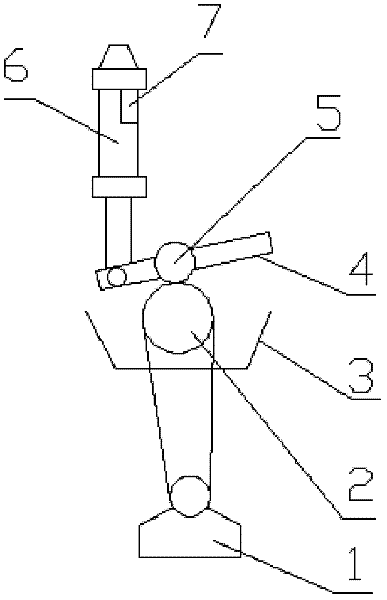

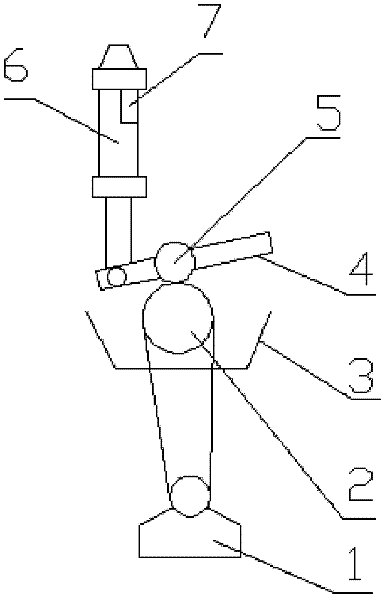

[0011] Such as figure 1 As shown, the anilox roller 2 is immersed in the rubber disc 3 and is driven by the motor 1. The upper rubber roller 5 is above the anilox roller 2 and is in line contact with it. The upper rubber roller 5 is installed in the middle of the movable rod 4, and the movable rod 4 One end is hinged to the frame, and the other end is connected to the piston rod of the cylinder 6 on which a pressure sensor 7 is installed.

[0012] The cylinder 6 drives the movable rod 4 to rotate around one end through the telescopic piston rod, and then drives the upper rubber roller 5 to move up and down to realize the pressure change with the anilox roller 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com