Apparatus for coating food

A technology for food and equipment, applied in the field of food surface coating equipment, can solve the problems of inability to automate the feeding of egg paste or oily food materials, increased labor intensity, long interval time, etc., to achieve unmanned operation, convenient operation and maintenance, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

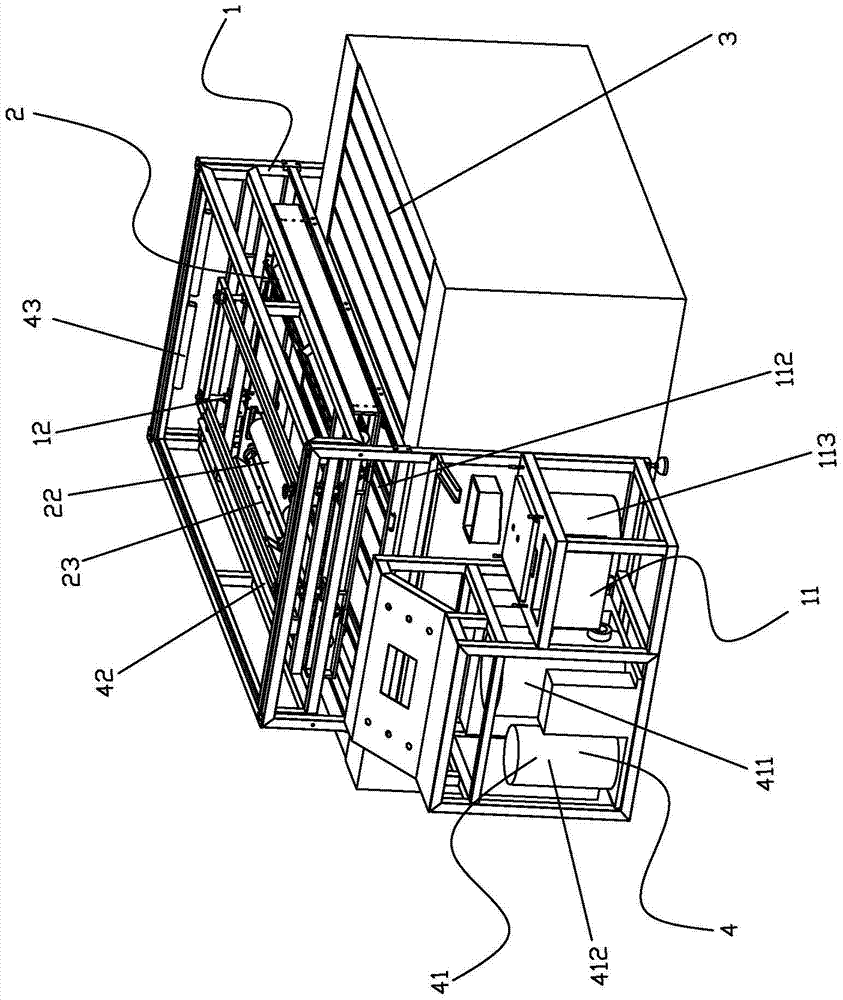

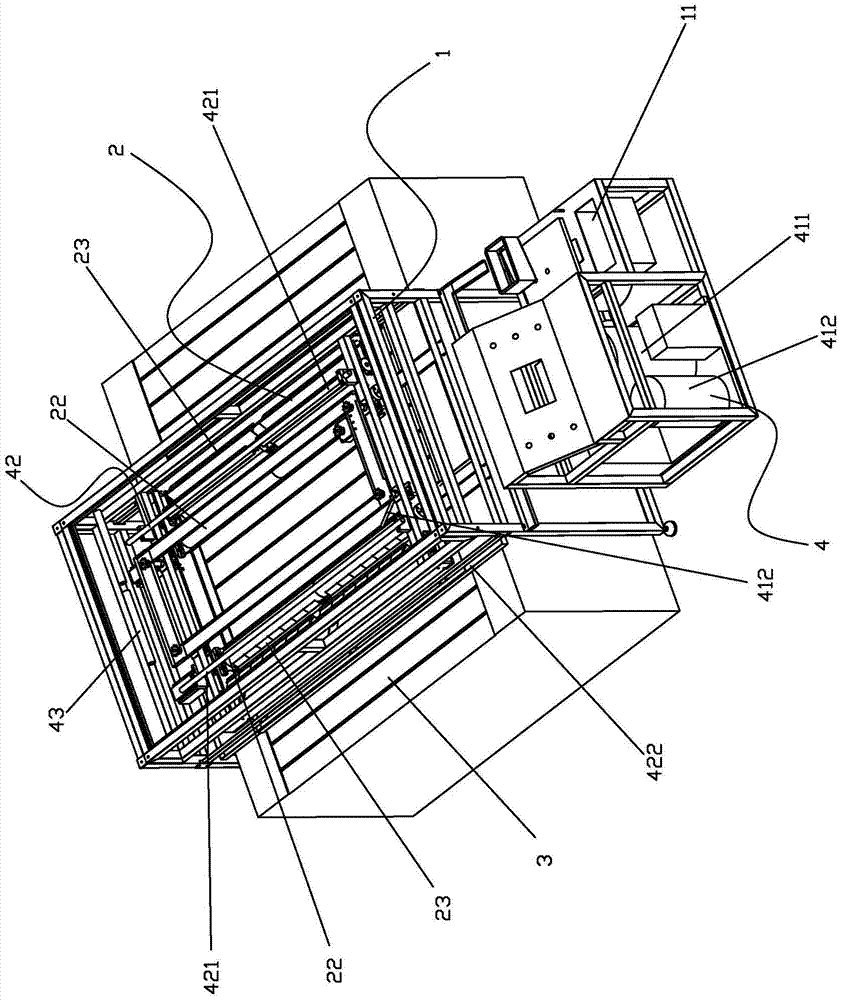

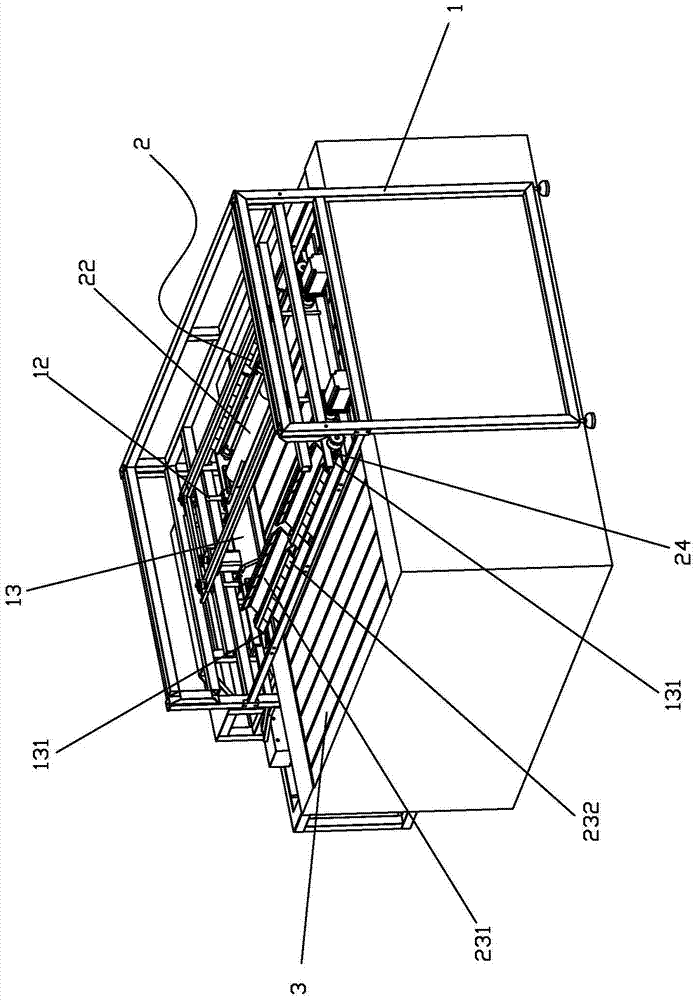

[0026] A food surface coating equipment, comprising a frame 1, the frame 1 is provided with an automatic coating mechanism 2 for coating egg slurry or oily food on the surface of food and a conveying conveyor for conveying food under the automatic coating mechanism 2 Mechanism 3, the automatic coating mechanism 2 includes a bottom tank 21 for containing egg slurry or oily food, a material roller 22 that adheres egg slurry or oily food to the surface from the bottom tank 21 when rotating, and is used to remove the egg slurry or oily food from the bottom tank 21. Dip egg slurry or oily food material on the material roller 22 and smear the material brush 23 on the food. The side of the bottom groove 21 near the material brush 23 is provided with a rib 210, and the rib 210 is used to control The dipping amount of egg slurry or oily food material dipped by the material brush 23 from the material roller 22 . Use the material roller to rotate and adhere egg slurry or oily ingredients...

Embodiment 2

[0036] A food surface coating equipment, comprising a frame 1, the frame 1 is provided with an automatic coating mechanism 2 for coating egg slurry or oily food on the surface of food and a conveying conveyor for conveying food under the automatic coating mechanism 2 Mechanism 3, the automatic coating mechanism 2 includes a bottom tank 21 for containing egg slurry or oily food, a material roller 22 that adheres egg slurry or oily food to the surface from the bottom tank 21 when rotating, and is used to remove the egg slurry or oily food from the bottom tank 21. Dip egg slurry or oily food material on the material roller 22 and smear the material brush 23 on the food. The side of the bottom groove 21 near the material brush 23 is provided with a rib 210, and the rib 210 is used to control The dipping amount of egg slurry or oily food material dipped by the material brush 23 from the material roller 22 . Use the material roller to rotate and adhere egg slurry or oily ingredients...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com