An automatic food spreading device

An automatic and food-based technology, applied in coating preservation, food science, baking, etc., can solve problems such as long intervals, denaturation of egg milk or oily ingredients, and increased labor intensity, and achieve the effect of ensuring quality and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

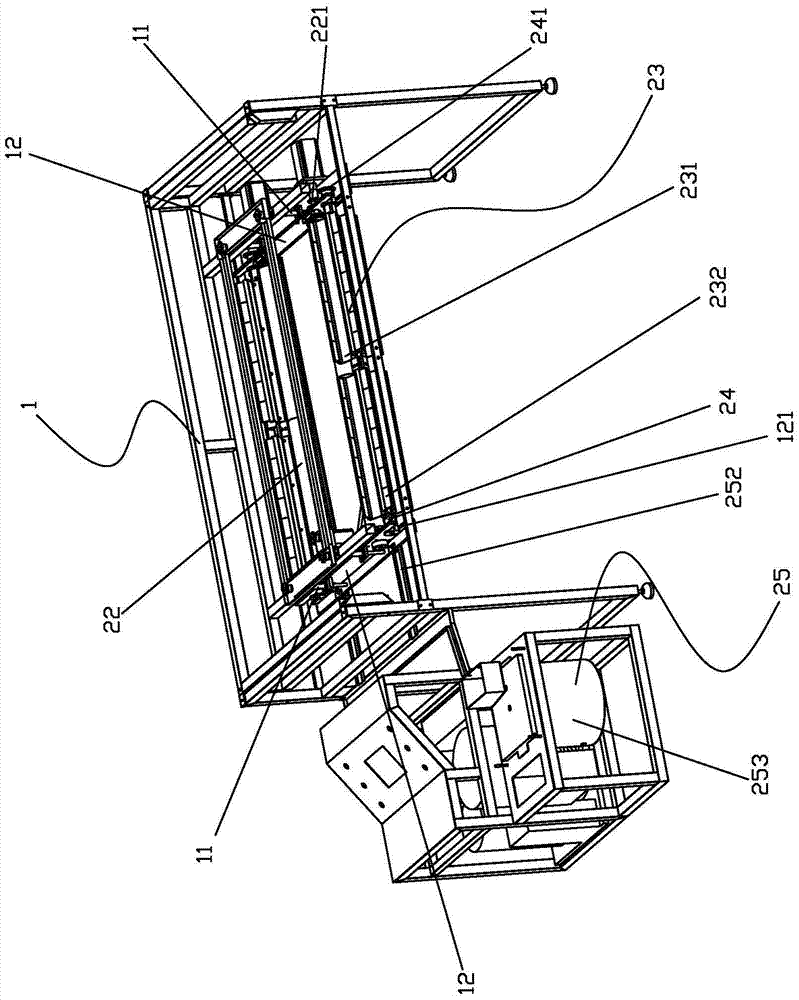

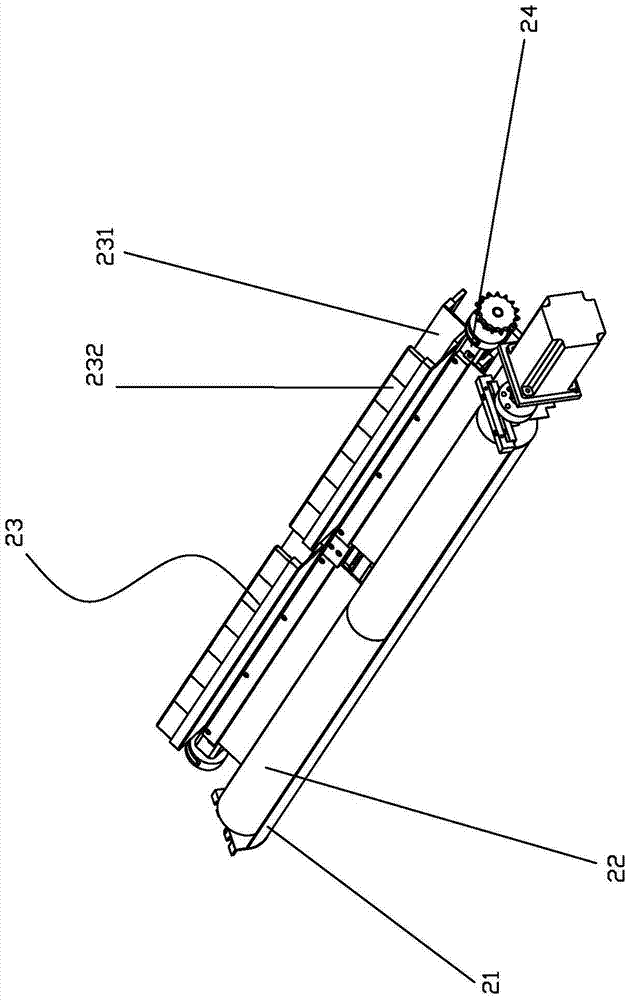

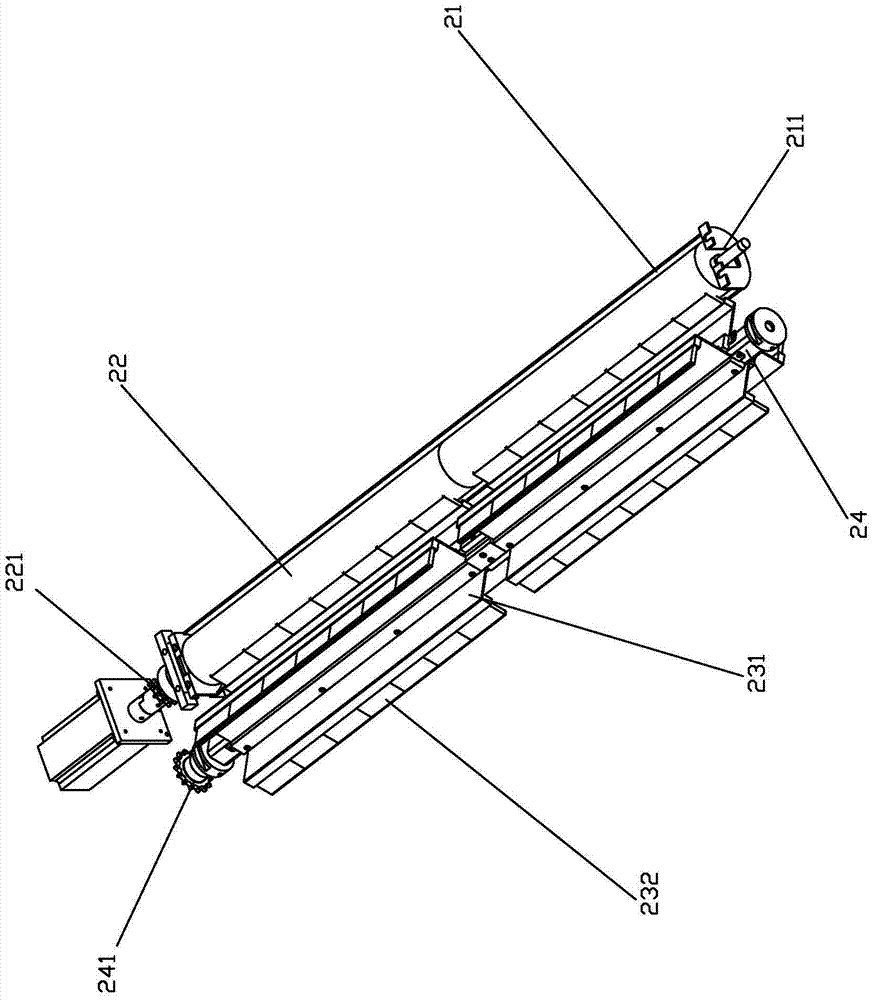

[0023] An automatic food coating device as shown in the figure includes a frame 1 on which an automatic coating mechanism for coating egg slurry or oily ingredients on the food surface is mounted, and the automatic coating mechanism includes a Or the bottom tank 21 of oily food, the top of the bottom tank 21 is provided with a material roller 22 for adhering the egg slurry or oily food in the bottom tank 21 by rotating on the surface, and the side of the material roller 22 is also provided with at least A material brush 23 for dipping egg slurry or oily food material from the material roller 22, and a side of the bottom groove 21 close to the material brush 23 is provided for controlling the material brush 23 from the material roller 23. 22. The edge of the dipping amount of the egg slurry or oily food to be dipped. Use the material roller to rotate and adhere the egg slurry or oily ingredients, and then use the material brush to dip the ingredients from the material roller. T...

Embodiment 2

[0033]A kind of food automatic smearing device shown in (not accompanying drawing) comprises frame 1, and the automatic smearing mechanism that is used for smearing egg slurry or oily food material on food surface is set up on described frame 1, and described automatic smearing mechanism includes containing Bottom trough 21 for carrying egg yolk or oily ingredients, above the bottom trough 21 is provided with a material roller 22 for adhering the egg yolk or oily ingredients in the bottom trough 21 by rotating on the surface, next to the material roller 22 there is There is at least one material brush 23 for dipping egg slurry or oily food material from the material roller 22, and a side of the bottom groove 21 close to the material brush 23 is provided for controlling the material brush 23 from the material brush 23. The sidewall of the amount of dipped egg slurry or oily food material that is dipped on the material roller 22. Use the material roller to rotate and adhere the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com