Mechanical adding equipment and operation control method for screw conveying pump lubricant

A technology of screw conveying and operation control, which is applied in the direction of mechanical equipment, computer control, program control, etc., can solve the problems of shortening the service life of equipment, large waste of lubricant, and high risk, so as to avoid equipment maintenance in place and oil injection consumption The effect of reducing the amount and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

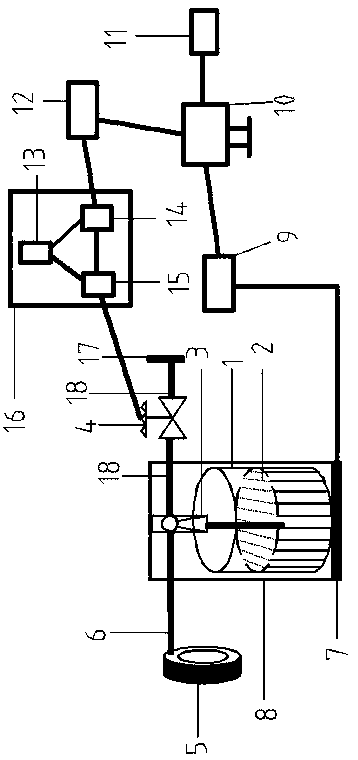

[0019] Device embodiment; such as figure 1 Shown: a mechanical adding equipment for screw conveying pump lubricant, including screw conveying pump bearing 5 and ring blowing air pipe 17; it is characterized in that: it also includes lubricant adding system, microcomputer controller system and storage tank alarm system; The delivery pump bearing is connected with the lubricant adding system, the lubricant adding system is connected with the microcomputer controller system, and the microcomputer controller system is connected with the storage tank alarm system.

[0020] The lubricant adding system adds lubricant to the bearings of the screw conveying pump, the microcomputer controller system controls the working time of the lubricant adding system, and the storage tank alarm system is used to detect the working efficiency of the agent adding system; the ring blowing air pipe is the powder bin of the mixing station equipped with existing facilities.

[0021] The lubricant adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com