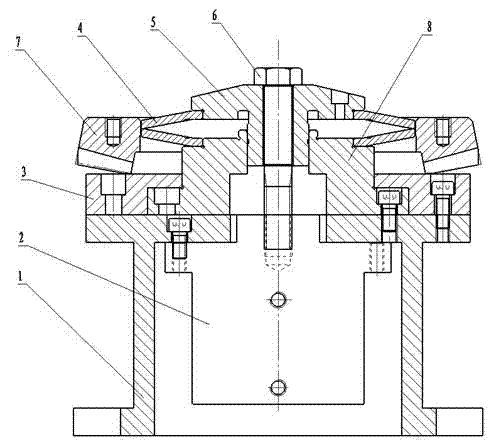

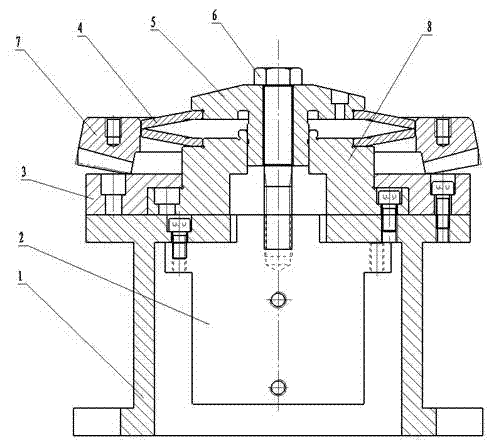

Bevel gear drill clamp

A drilling jig, bevel gear technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problem of low versatility of the three-jaw chuck, and achieve the effects of strong versatility, accurate positioning and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0009] The present technology will be further described below through embodiments in conjunction with the accompanying drawings.

[0010] like figure 1 The shown bevel gear drilling fixture includes a base 1, a hydraulic cylinder 2, a backing plate 3, a spring expansion piece 4, a pressure plate 5, a bolt 6, and a mandrel 8. The hydraulic cylinder 2 , the backing plate 3 and the mandrel 8 are all fixed on the base 1 . The lower inner hole of the spring expansion sheet 4 is in clearance fit with the mandrel 8 . The steps of the pressing plate 5 are in clearance fit with the inner hole of the spring expansion sheet 4 . The tension bolt 6 is connected to the hydraulic cylinder 2. When working, the hydraulic cylinder 2 pulls the bolt 6 to move downward, so that the spring expansion piece 4 expands and tightens the workpiece 7.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap