Frame and rotary bearing seat structure of frame

A technology for a slewing bearing seat and a vehicle frame, which is applied in the mechanical field, can solve the problems affecting the structural strength of the rib plate, the stress flow is prone to sudden change, and the local stress concentration, etc., to achieve the effect of smooth stress flow, avoiding stress sudden change, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

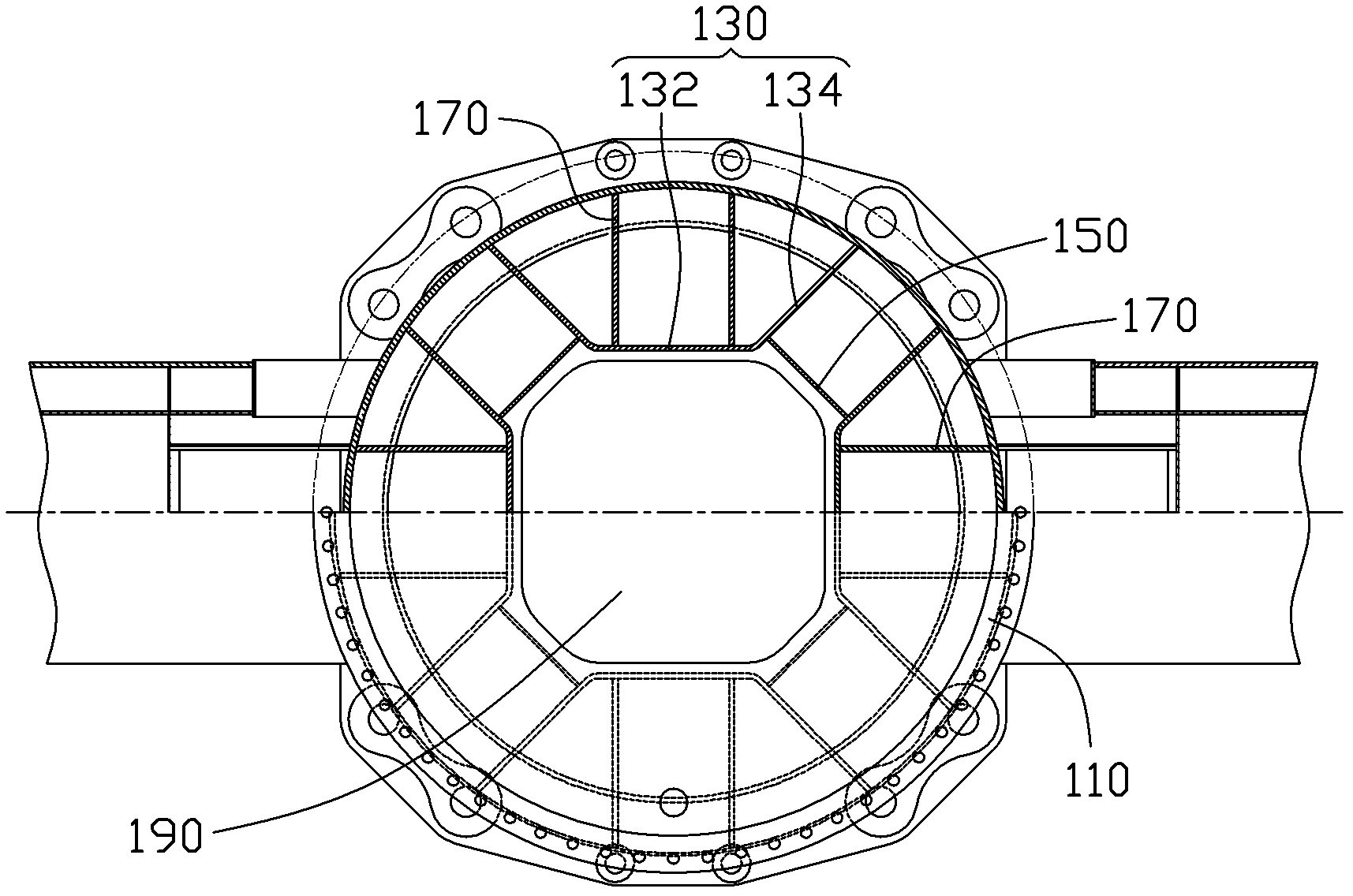

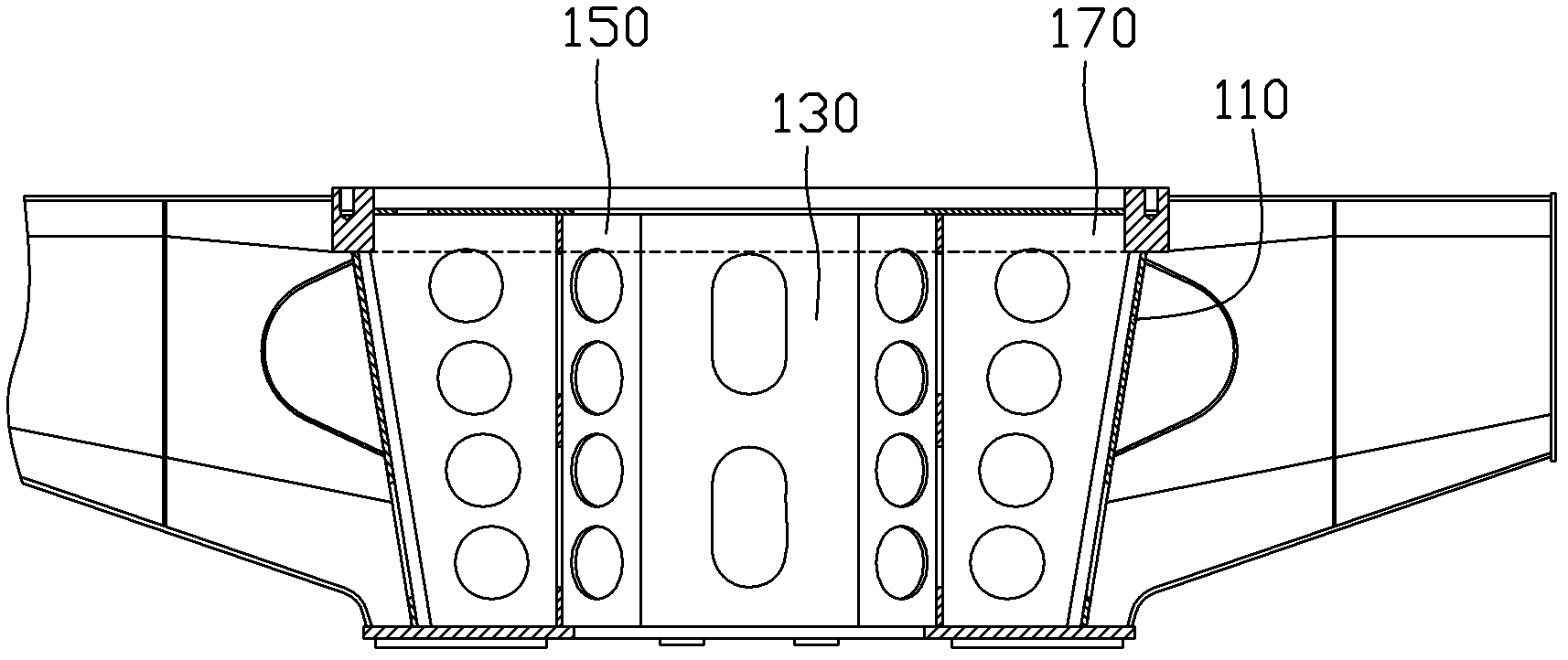

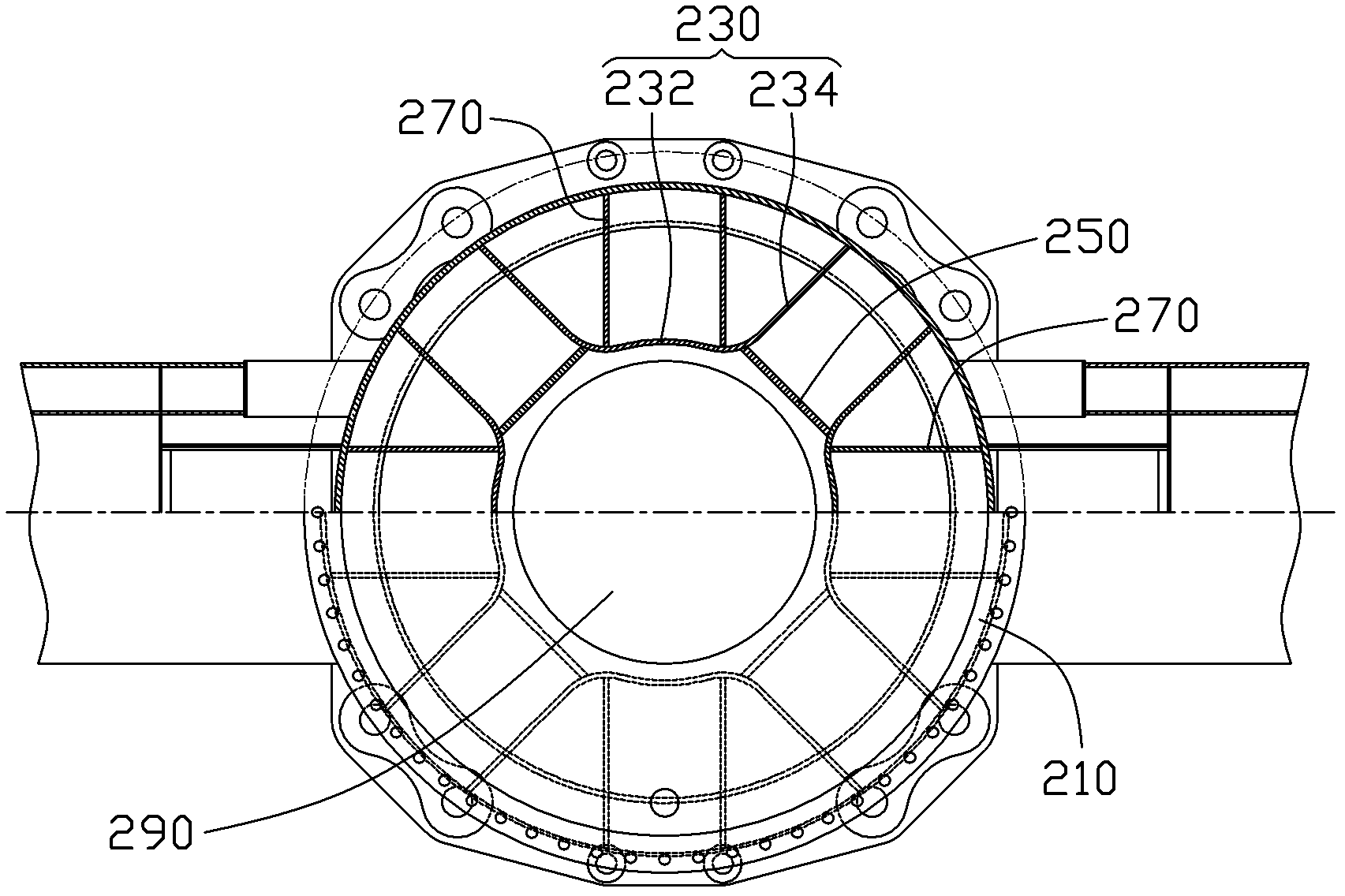

[0022] see figure 1 and figure 2 , The vehicle frame slewing support seat structure of the first embodiment of the present invention includes a slewing center seat 110 , a number of first ribs 130 , a number of second ribs 150 and a number of third ribs 170 . The rotary center seat 110 is in the shape of a cone, and the first rib 130 , the second rib 150 and the third rib 170 are fixed in the rotary center seat 110 . The first ribs 130 are radially arranged at intervals around the axis of the rotating center base 110 . The first rib 130 includes a flat main rib 132 and wing plates 134 integrally bent from two ends of the main rib 132 . The wing plate 134 is connected with the inner wall of the rotary center base 110 . There is an arc transition between the wing plate 134 and the main rib 132 , and an obtuse angle between the wing plate 134 and the corresponding main rib 132 . The second rib 150 is fixedly connected to the wing plate 134 of the adjacent first rib 130 by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com