Dispersing agent for reusing reclaimed water prepared from production wastewater as circulating cooling water and preparation method

A technology for circulating cooling water and production wastewater, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. To achieve the effect of good scale inhibition and long-term treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

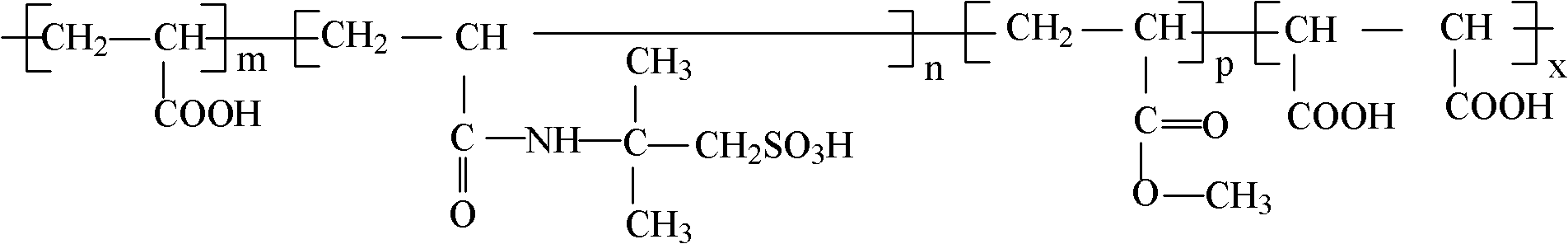

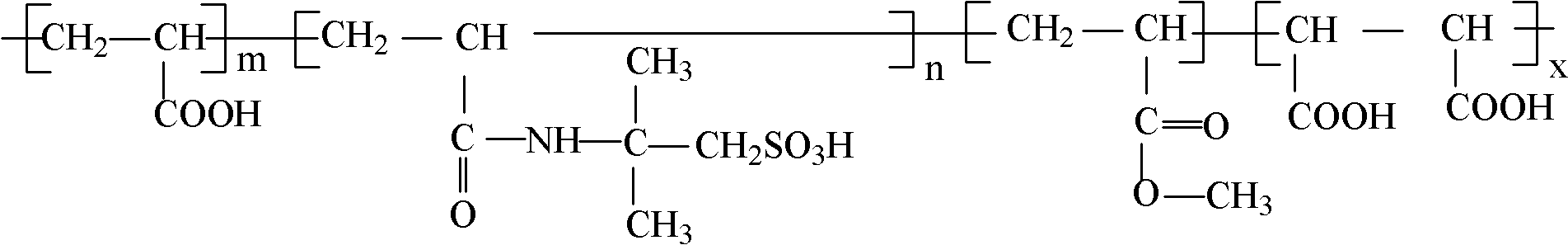

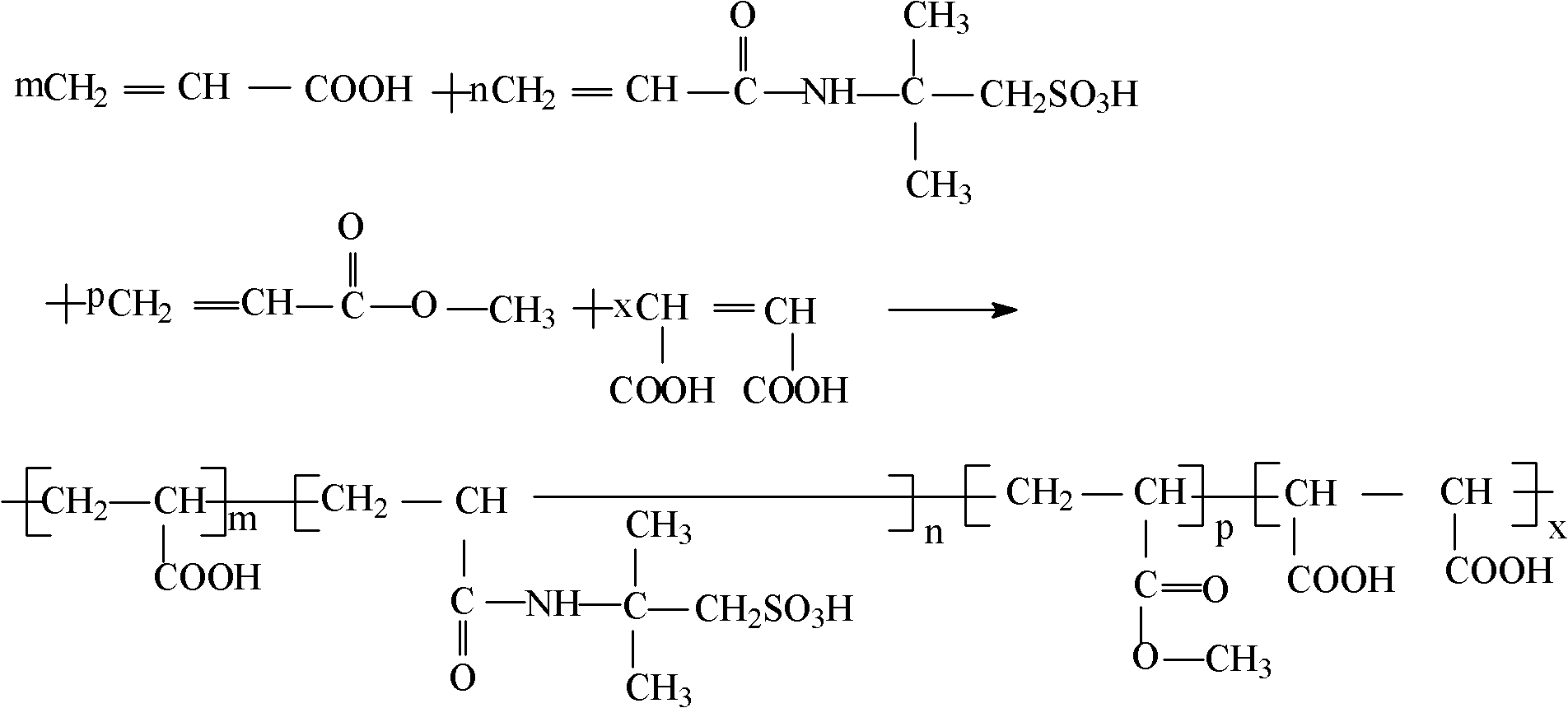

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the dispersant used in circulating cooling water for reclaimed water from production wastewater comprises the following steps:

[0042] 1) Raw material preparation and dosing

[0043] a. Primer preparation and dosing: First, 300kg of deionized process water and 75kg of isopropanol are sucked into the reaction kettle through a vacuum pump in sequence, so that the liquid level in the reaction kettle is above the minimum liquid level of stirring, and then from the inlet of the reaction kettle Add 115kg maleic anhydride, start stirring, and stir at room temperature until the solid raw material is fully dissolved;

[0044]b. Preparation of No. 1 monomer solution: suck 32kg of methyl acrylate and 66kg of acrylic acid into No. 1 high-level tank respectively through a vacuum pump. After the two raw materials are sucked, vacuumize for 5 minutes to mix the two raw materials evenly to form No. 1. Monomer solution;

[0045] c. Preparation of No. 2 monome...

Embodiment 2

[0055] The preparation method of the dispersant used in circulating cooling water for reclaimed water from production wastewater comprises the following steps:

[0056] 1) Raw material preparation and dosing

[0057] a. Primer liquid preparation and dosing: First, 360kg of deionized process water and 75kg of isopropanol are sucked into the reaction kettle through a vacuum pump in sequence, so that the liquid level in the reaction kettle is above the minimum liquid level of stirring, and then from the inlet of the reaction kettle Add 120kg maleic anhydride, start stirring, and stir at room temperature until the solid raw material is fully dissolved;

[0058] b. Preparation of No. 1 monomer solution: suck 40kg of methyl acrylate and 90kg of acrylic acid into No. 1 high-level tank respectively through a vacuum pump. After the two raw materials are sucked, vacuumize for 6 minutes to mix the two raw materials evenly to form No. 1. Monomer solution;

[0059] c. Preparation of No. ...

Embodiment 3

[0069] The preparation method of the dispersant used in circulating cooling water for reclaimed water from production wastewater comprises the following steps:

[0070] 1) Raw material preparation and dosing

[0071] a. Primer preparation and dosing: First, 300kg of deionized process water and 50kg of isopropanol are sucked into the reactor through a vacuum pump in sequence, so that the liquid level in the reactor is above the minimum liquid level of stirring, and then from the inlet of the reactor Add 80kg of maleic anhydride, start stirring, and stir at room temperature until the solid raw materials are fully dissolved;

[0072] b. Preparation of No. 1 monomer solution: suck 30kg of methyl acrylate and 60kg of acrylic acid into No. 1 high-level tank respectively through a vacuum pump. After the two raw materials are sucked, vacuumize for 3 minutes to mix the two raw materials evenly to form No. 1. Monomer solution;

[0073] c. Preparation of No. 2 monomer solution: Put 30k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com