Bio-enzyme treating agent for oil field and preparation method and application thereof

A biological enzyme and treatment agent technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of scrapped production cost, production efficiency decline and increase of production oil and water wells, and meet the requirements of reaction conditions The effect of not high, prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

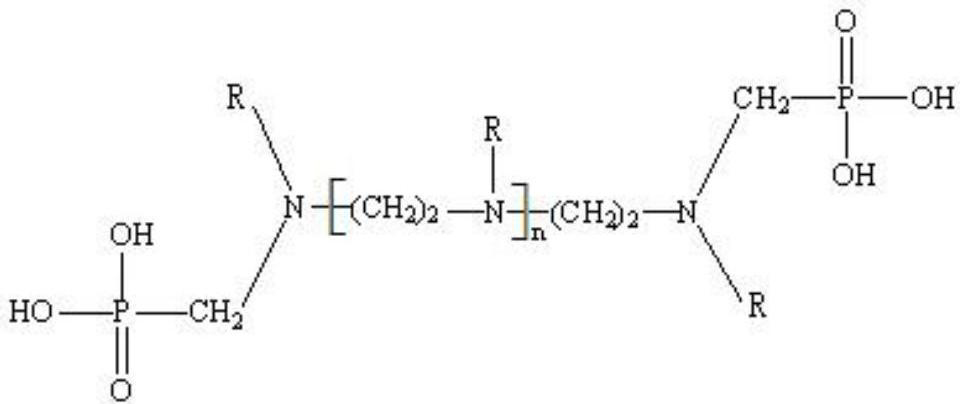

[0040] The present invention also provides a preparation method of a biological enzyme treatment agent for oilfields, comprising: sequentially adding biological enzymes, polycarboxylic acid dispersants, penetrants, modifiers and water into the reaction kettle at a temperature of 58 to After stirring for 6-8 hours under the conditions of 62° C. and a rotating speed of 300 r / min to 400 r / min, the mixture is cooled to room temperature to obtain the biological enzyme treatment agent for oilfields.

[0041] The present invention also provides the application of the biological enzyme treatment agent for oil field, which is used for the comprehensive treatment of corrosion, scaling and waxing of wellbore or gathering and transportation system. The biological enzyme treatment agent used in the oil field is added to the annulus of the oil well or the agent is pumped into the gathering and transportation system by the dosing tank. Preferably, the added amount of the oilfield biological ...

Embodiment 1

[0066] The invention provides a biological enzyme treatment agent for oil fields. The raw material composition of the bio-enzyme treatment agent for oil fields includes: sequentially adding 30% bio-enzyme, 40% triethylene tetramine hexamethylene phosphonic acid, 2% environment-friendly penetrant JFC, 10% modifier polyethylene emulsion HA-soft80 and 18 % water. Turn on the stirring device of the reactor, set the rotation speed at 300r / min-400r / min, heat to 60°C±1°C, stir for 6 hours, then cool down to room temperature to obtain the biological enzyme treatment agent for oil field.

[0067] Since 2012, in a block of Jiyuan oilfield, wellbore corrosion and scaling have appeared year by year. The pipelines of the gathering and transportation system in the Ji 28 transfer station have been repaired twice a year on average, and the pipelines of the water injection system have been repaired 18 times a year on average, seriously affecting crude oil production.

[0068] Table 1 shows th...

Embodiment 2

[0079] The invention provides a biological enzyme treatment agent for oil fields. The raw material composition of the bio-enzyme treatment agent for oil fields includes: sequentially adding 35% bio-enzyme, 23% triethylene tetramine hexamethylene phosphonic acid, 12% environment-friendly penetrant JFC, 15% modifier polyethylene emulsion HA -soft80 and 18% water. Turn on the stirring device of the reactor, set the rotation speed at 300r / min-400r / min, heat to 60°C±1°C, stir for 8 hours, then cool down to room temperature to obtain the biological enzyme treatment agent for oil field.

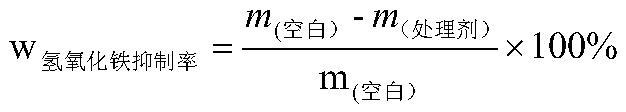

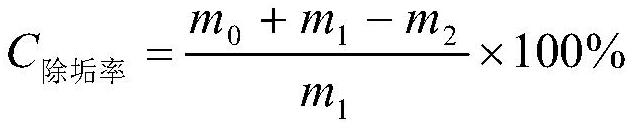

[0080] The performance of the above-mentioned oilfield biological enzyme treatment agent of the present embodiment has been tested indoors, and its quality technical test of the oilfield biological enzyme treatment agent is as follows in table 4:

[0081] Table 4 oil field biological enzyme treatment agent performance test results

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com