Stripping, backfilling and conveying system for open-pit mines

A conveying system and technology for open pit mines, which are applied in fillings, mining equipment, safety devices, etc., can solve the problems of low transportation efficiency and high cost of dump trucks, and achieve the effect of shortening transportation distance, reducing transportation cost and improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

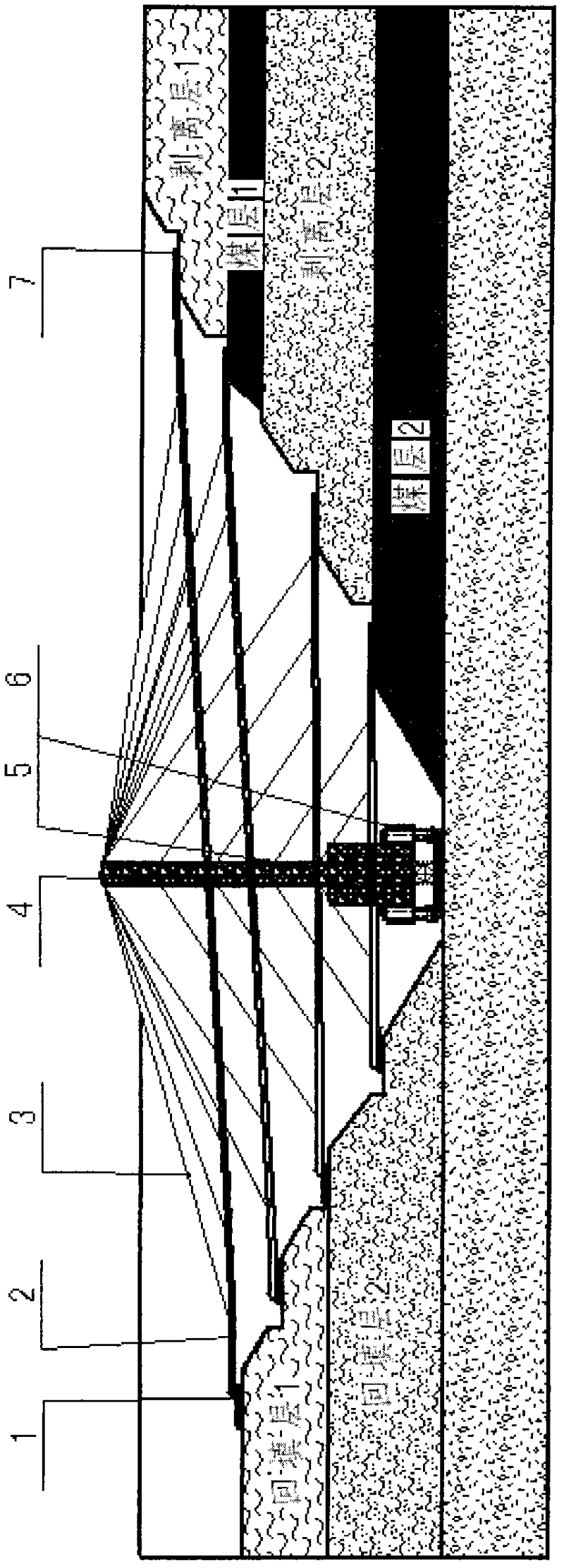

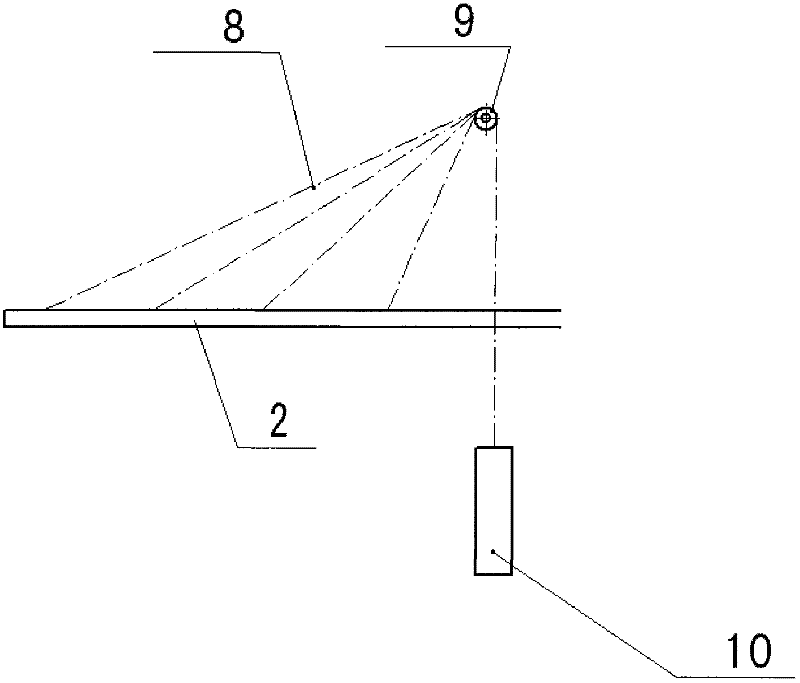

[0013] Depend on Figure 1~3 As shown, the conveying system is composed of a mobile rotary unloading vehicle 1, a belt conveyor 2, a gravity balance mechanism 3, a tower frame 4, a platform 5, a mobile lifting rotary crane 6, and a mobile traction crushing vehicle 7; the tower frame 4 is a multi-section The trusses are connected sequentially. The lower part of the tower 4 is placed in the guide shaft of the mobile elevating and slewing crane 6 and is fixedly connected with the crane; On the bottom plane; multi-layer platforms are arranged on the tower 4 (according to the terrain of the mining area), and the vertical distance between the two platforms on the tower 4 is 8-10 meters; each platform is arranged with a belt conveyor 2, each The transmission part of the belt conveyor 2 is respectively installed on the multi-layer platform of the tower 4, the transmission part of the belt conveyor 2 is located in the middle of the belt conveyor 2, and the belt of the belt conveyor 2 i...

Embodiment 2

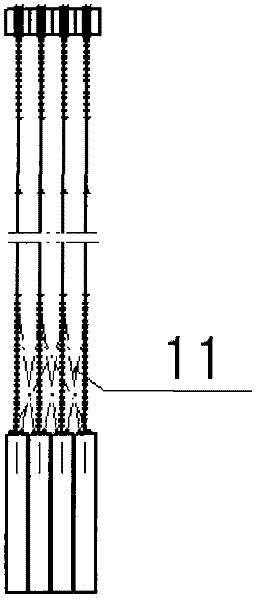

[0020] The difference between this embodiment and Embodiment 1 is that the traction device 8 is composed of a circular link chain and a tension rod indirectly connected. The tension rod is used to reduce the cost, and the tension rod is used in the linear tension section.

[0021] The mobile rotary unloading vehicle 1, the belt conveyor 2, the mobile lifting rotary crane 6 and the mobile traction crushing vehicle 7 of the present invention belong to the supporting equipment of this conveying system, and all are prior art products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com