Bidirectional thrust bearing supported by drum-shaped elastic oil tanks

A bidirectional thrust bearing and elastic oil tank technology, applied in the direction of flexible bearings, bearings, bearing components, etc., can solve the problems that are difficult to meet the development needs of pumped storage units, generators and electric units, and achieve convenient installation and debugging, improved safety, and maintenance. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

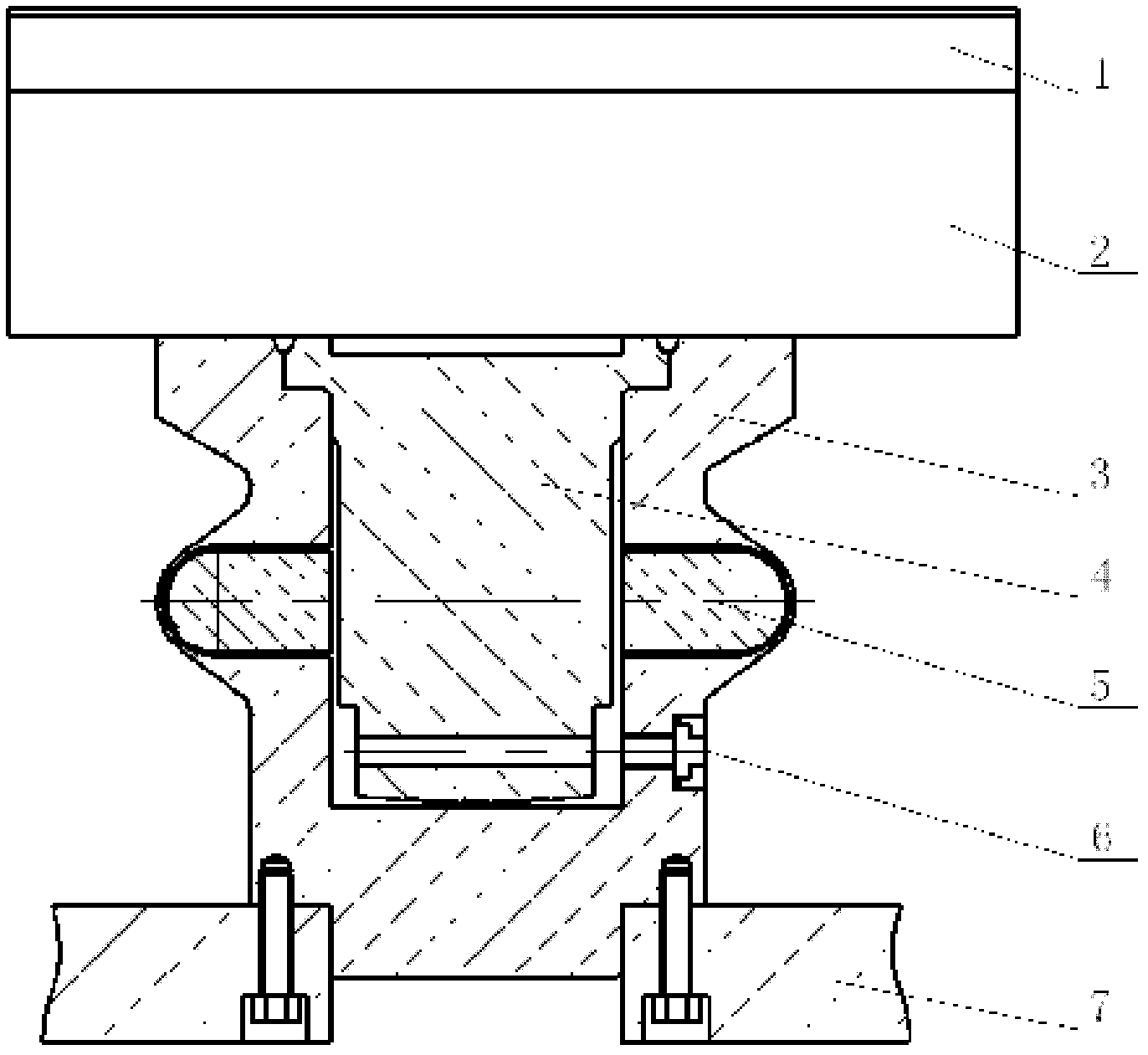

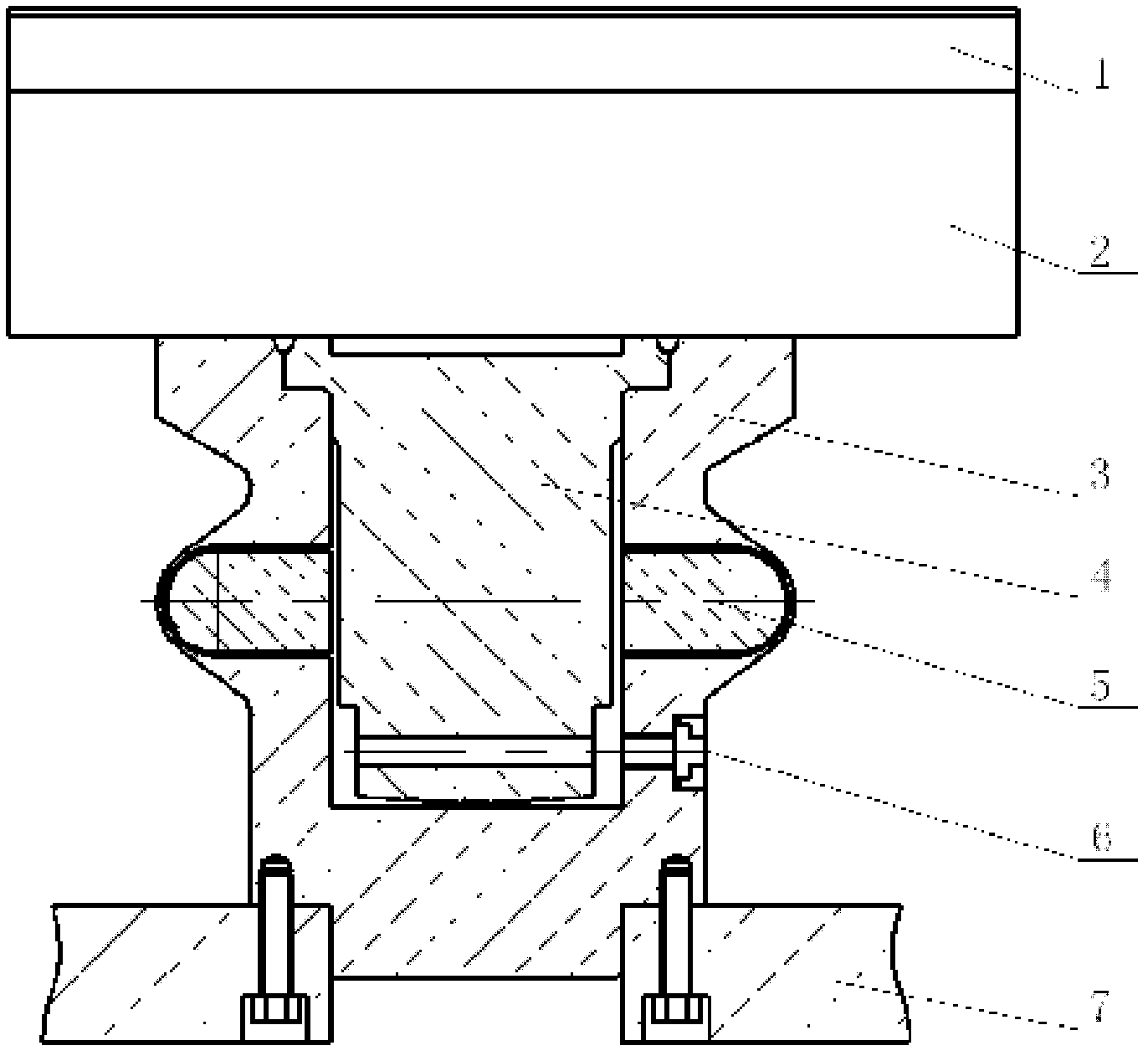

[0009] Such as figure 1 As shown, a drum-shaped elastic oil tank supports a bidirectional thrust bearing, which is composed of the following components: Babbitt alloy tile 1, support pad 2, drum-shaped elastic oil tank 3, supporting iron 4, ring 5, connecting pipe 6, bearing seat 7 . The babbitt alloy bush 1 and the support bush 2 are connected by a key and form a thrust bearing bush. The thrust bearing bush is supported on the drum-shaped elastic oil tank 3. The spherical support 4 and the ring 5 are located in the drum-shaped elastic oil tank 3. The oil tanks 3 are communicated with each other through the connecting pipe 6, and the drum-shaped elastic oil tank 3 filled with hydraulic oil is fixedly installed on the bearing seat 7.

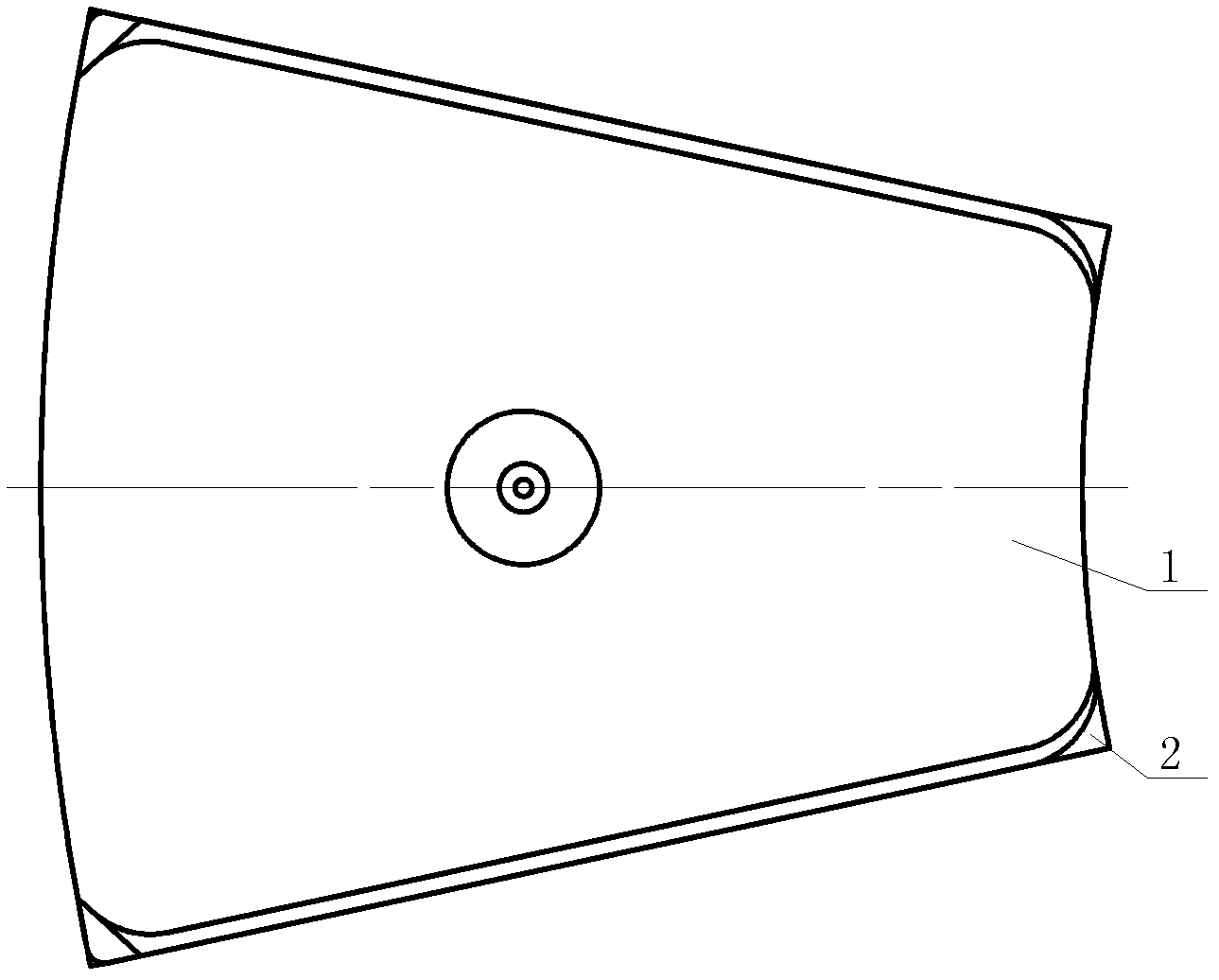

[0010] Such as figure 2 As shown, the axisymmetric structure of the drum-shaped elastic oil tank ensures that its upper surface is inclined under the action of the oil film pressure on the tile surface without being restricted by the direction. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com