Rope driving mechanism frame, rope driving mechanism and engineering machinery

A rope drive and frame body technology is applied in the field of rope drive mechanisms, construction machinery, and rope drive mechanisms, and can solve the problems of accelerated rope wear, affecting the working reliability of the rope drive mechanism, and rope slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

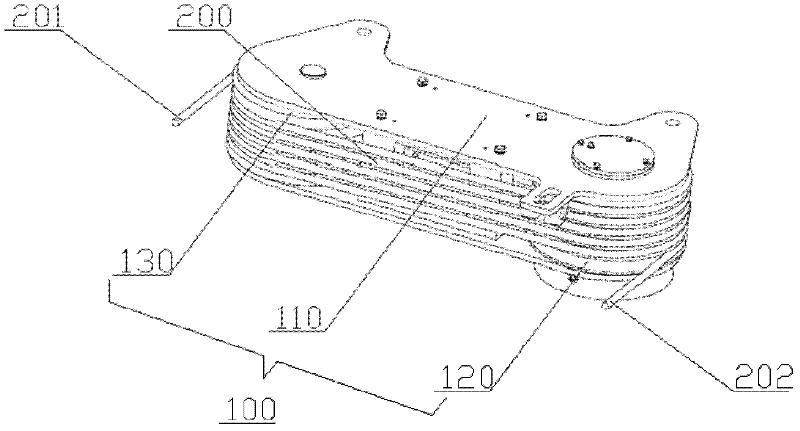

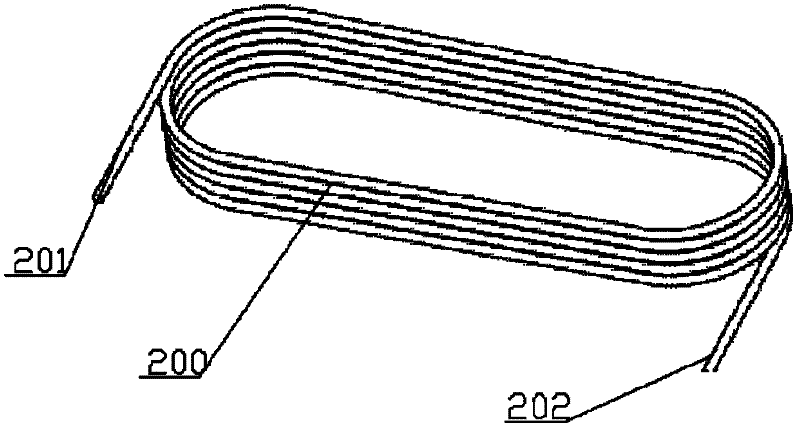

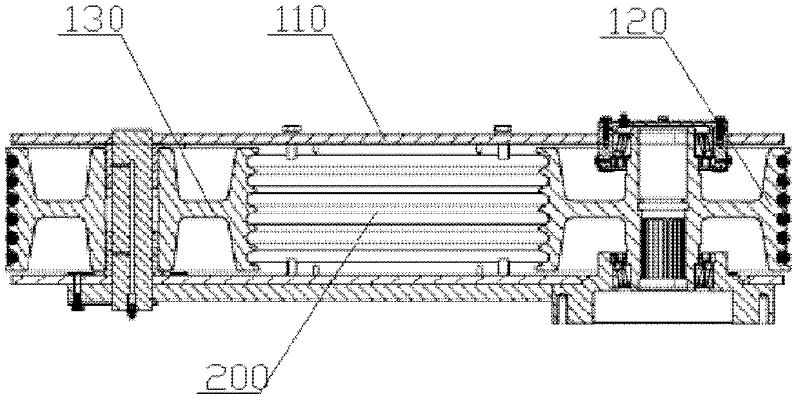

[0031] The applicant analyzed the reasons for the slipping of the rope drive mechanism described in the background art section. Please refer to Figure 4 , which shows a transverse cross-sectional view of the cable drive mechanism in the Background Art section. The contact portion between the rope 200 and the second runner 130 rope groove and the contact portion between the rope 200 and the first runner 120 rope groove form corresponding rope wrap angles respectively; Figure 4 As shown, when the radii of the second runner 130 and the first runner 120 are equal (the distance between the axis of rotation and the outer edge), the rope wrap angles formed on the second runner 130 and the first runner 120 are equal. is 180 degrees. After analysis, the applicant believes that: the reason for the slippage of the rope drive mechanism is that the rope wrap angle formed on the runner is too small, resulting in a decrease in the friction between the rope and the corresponding runner; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com