Optical fiber composite contact case for measuring temperature of high-voltage switch contacts and production method thereof

A fiber optic composite, high-voltage switch technology, used in thermometers, measuring devices, measuring heat, etc., can solve the problems of reduced air clearance, easy to fall off, and reduced insulation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

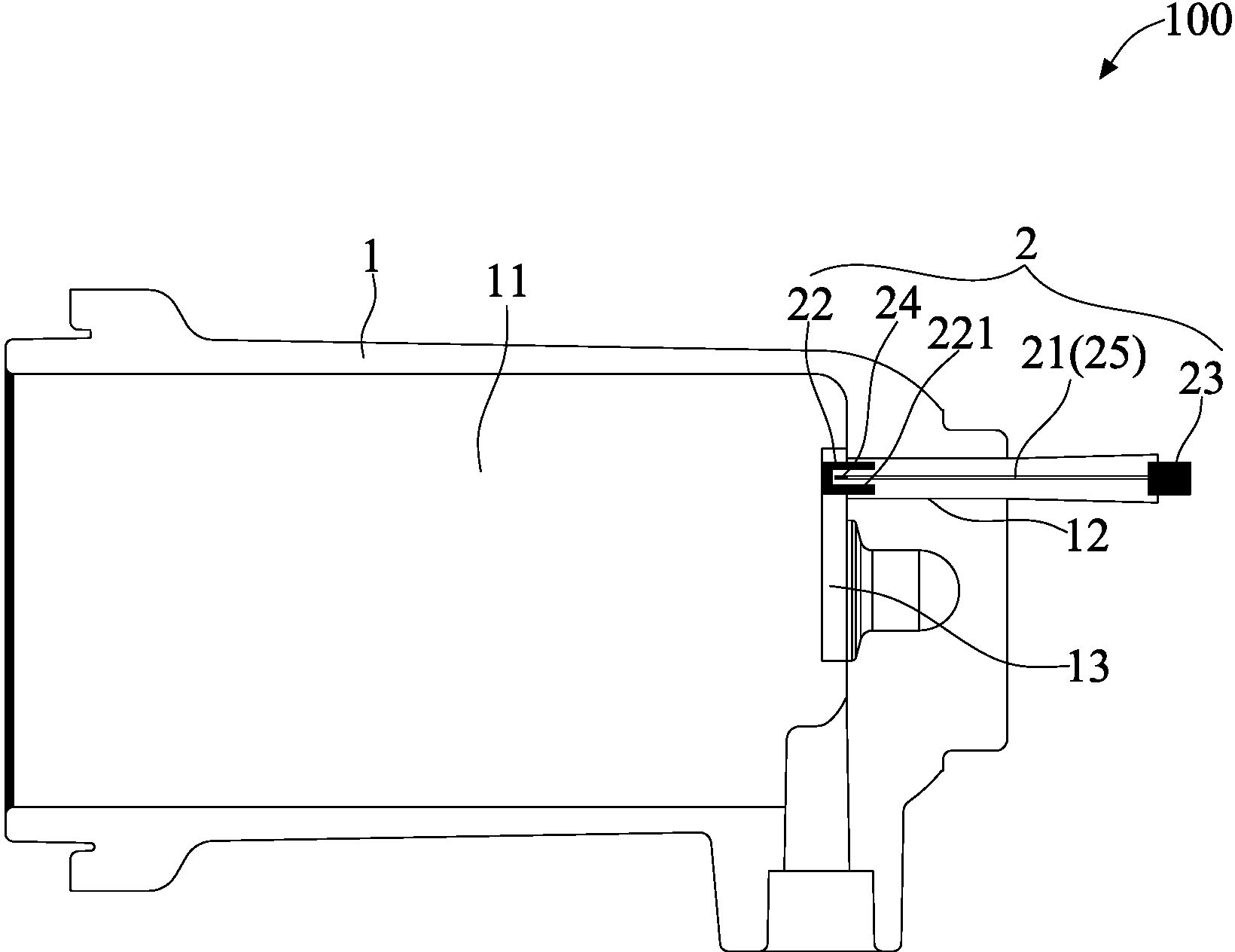

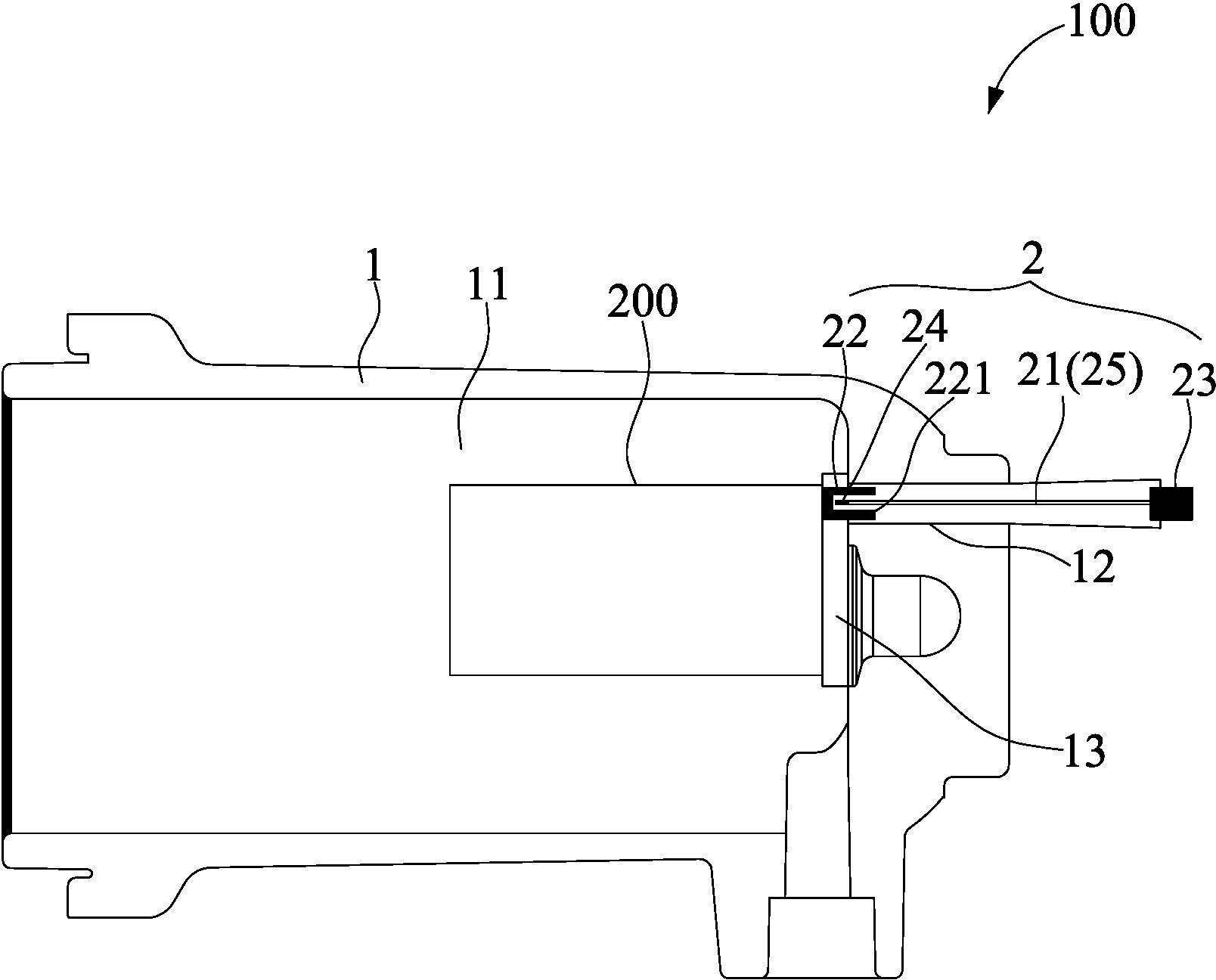

[0036] Such as Figure 1 to Figure 3 As shown, it is a preferred embodiment of an optical fiber composite contact box 100 for measuring the temperature of a high-voltage switch contact according to the present invention. The fiber optic composite contact box 100 includes a contact box body 1 and a temperature measuring insert 2, wherein:

[0037] The contact box body 1 has a chamber 11 and a through hole 12 communicating with the chamber 11. The chamber 11 can accommodate the static contact 200 therein. The through hole 12 is preferably a cylindrical hole or a truncated cone. hole;

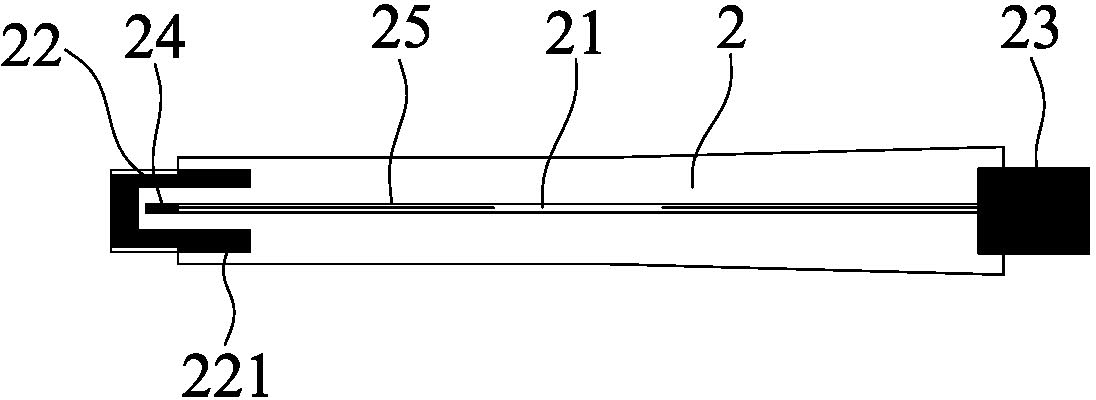

[0038] The temperature measuring insert 2 has an optical fiber 21, a heat conducting insert 22 and an optical fiber interface insert 23. The optical fiber 21, the heat conducting insert 22 and the optical fiber interface insert 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com