Detection method and detection device for hinged gap of plate-girder-hinged bridge

A detection device and detection method technology, applied in the direction of material resistance, etc., can solve the problem of difficulty in finding damage or destruction of hinge joints in time, and achieve the effects of simple structure, low manufacturing cost, and saving construction time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with embodiment:

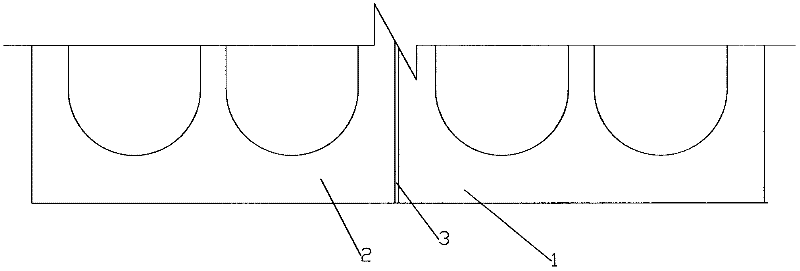

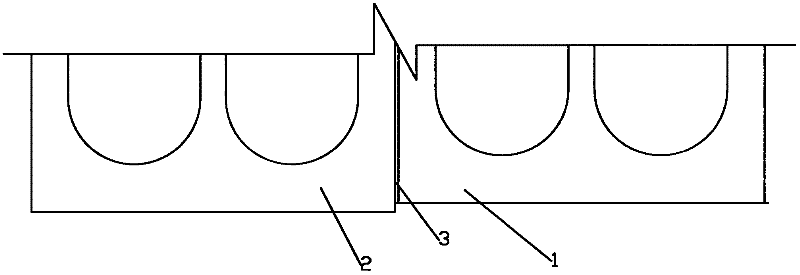

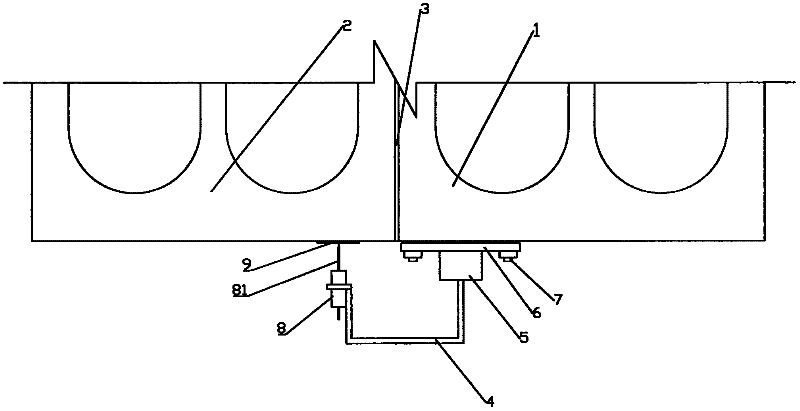

[0034] Such as image 3 As mentioned above, the tested hinged plate girder bridge includes plate girder 1 and plate girder 2 . There is a hinged seam 3 between the plate girder 1 and the plate girder 2 . After the hinge joint 3 is damaged, the plate girder 1 and the plate beam 2 on both sides may have relative displacements in two directions. The relative height of the bottom surface changes; the second is the horizontal relative displacement, that is, the hinge seam 3 becomes wider or narrower.

[0035] The hinge detection device of the hinged slab girder bridge includes a fixing device and a resistive displacement meter 8 . The fixing device includes a U-shaped bracket 4, a magnetic table base 5 and a steel plate 6. The steel plate 6 is fixedly installed on the plate girder 1 through expansion bolts 7 . The magnetic watch base 5 is fixed on the steel plate 6 by magnetic force. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com