Simple high-g (gravity) acceleration shock testing machine

A shock test, acceleration technology, applied in the direction of velocity/acceleration/shock measurement, testing/calibration of velocity/acceleration/shock measuring equipment, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

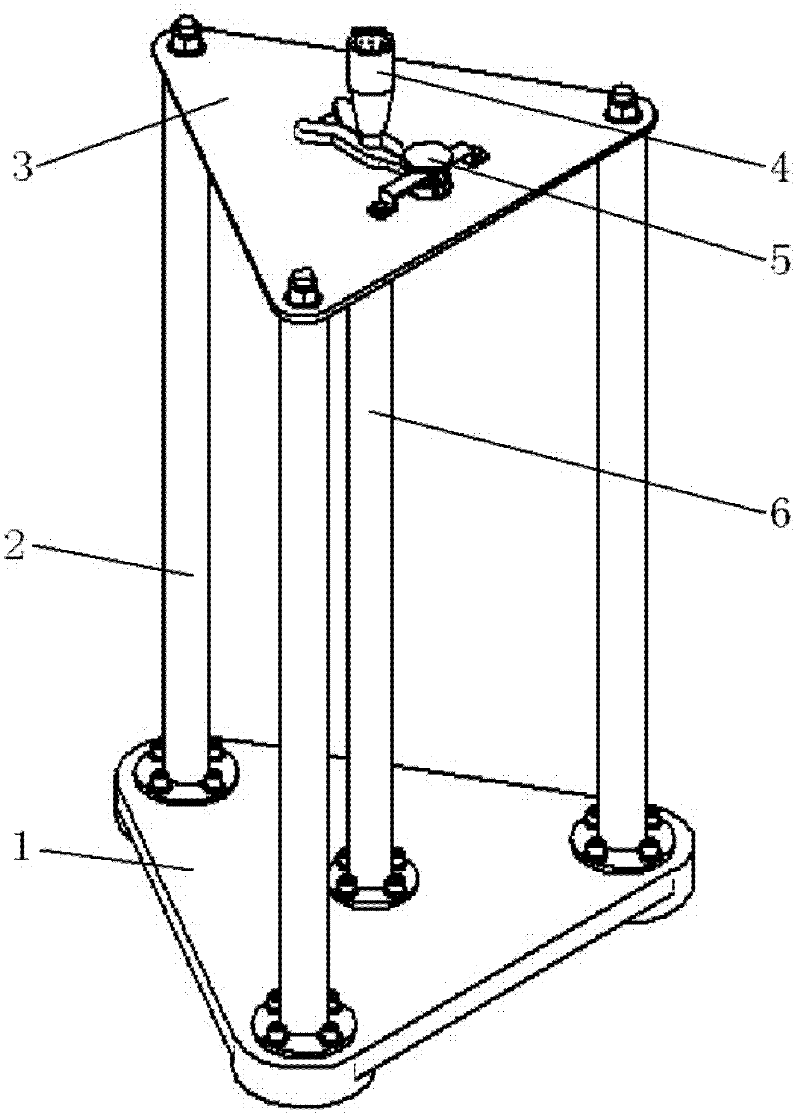

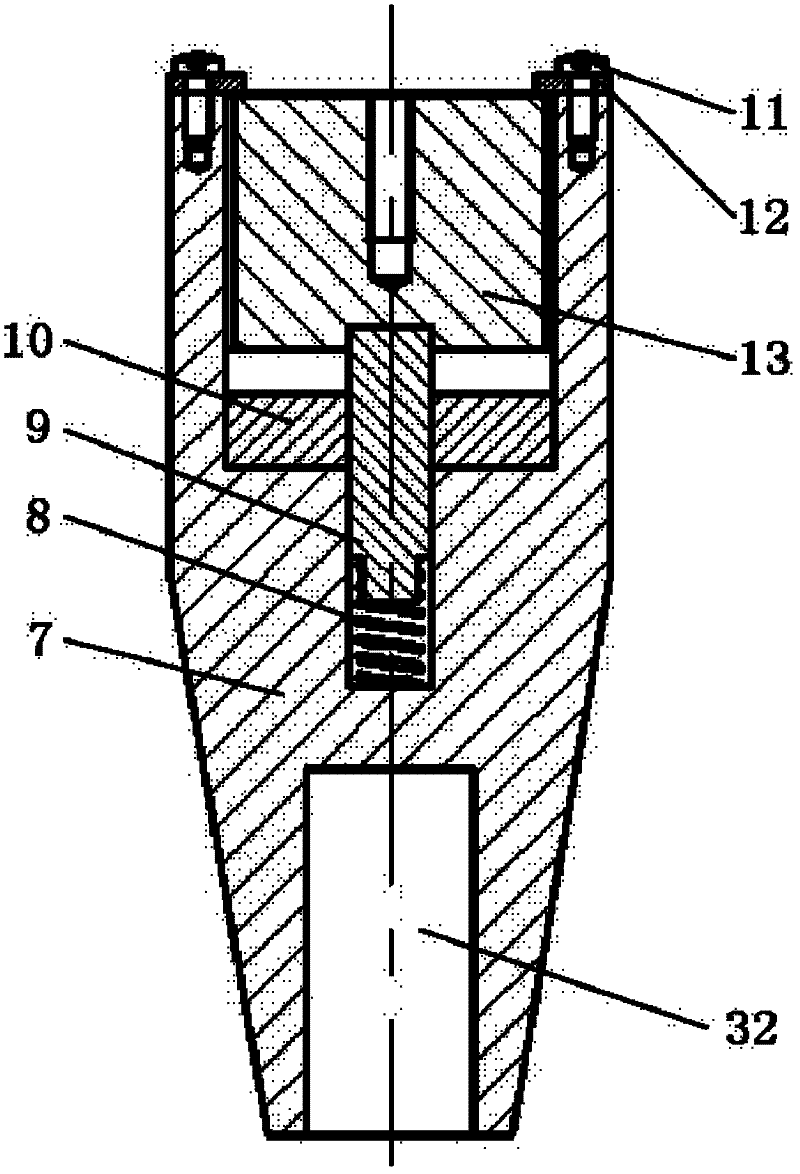

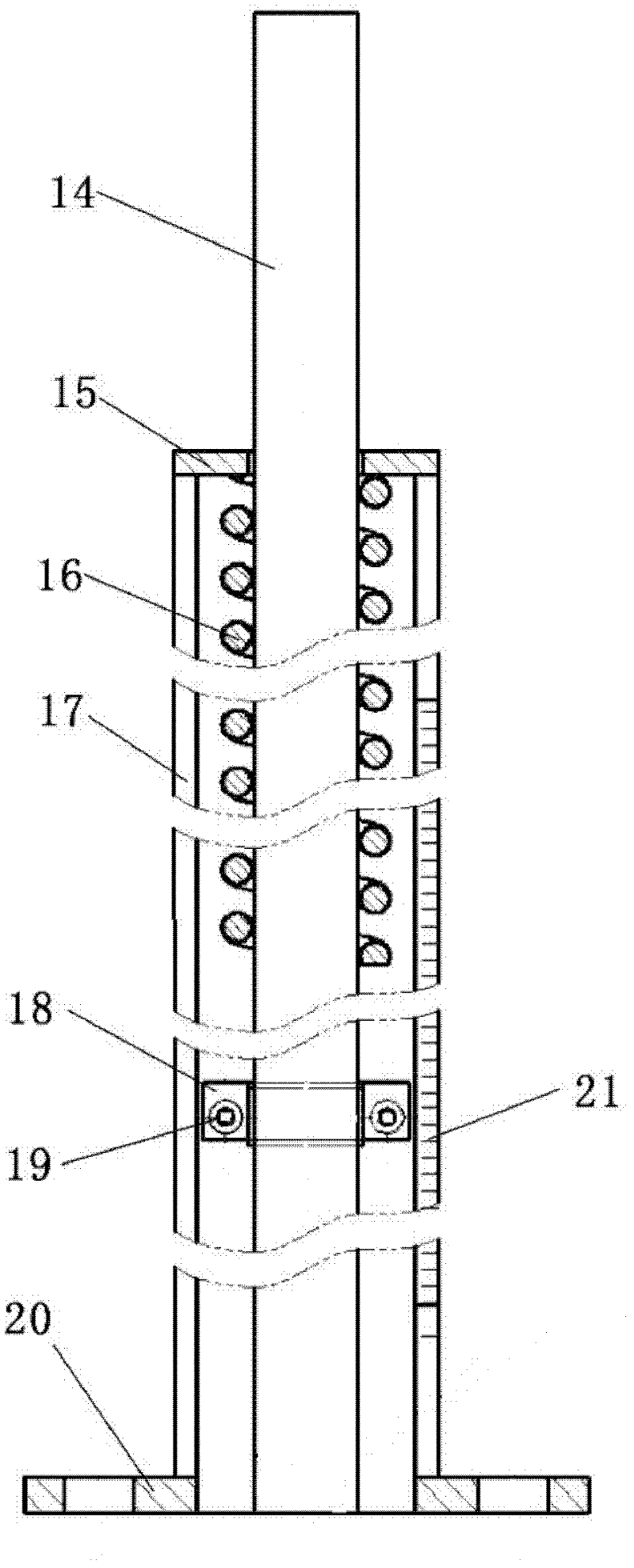

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , a simple high-g-value acceleration shock test bench, including a base 1, a column 2, an upper seat 3, a response head assembly 4, a clamping control assembly 5 and a punch assembly 6, and the column 2 is connected to the base by bolts through the flange 1 connection, connected with the upper seat 3 by bolts to form a device bracket; the response head assembly 4 is connected with the punch rod 14 of the punch rod assembly 6 through the connection hole 32 at the lower end of the punch rod upper seat 7; the clamping control assembly 5 passes through the clamping rod 23 and its pin shaft are fixed on the upper seat 3 with a circlip 29, and are fixed with the upper seat 3 through the clamping rod limit bracket 26 and the clamp rod limit bracket bolt 28 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com