Conveying mechanism

A technology of conveying mechanism and lifting mechanism, which is applied in the direction of conveyor objects, transportation and packaging, sustainable manufacturing/processing, etc., and can solve problems such as loss, fragile cells, and twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

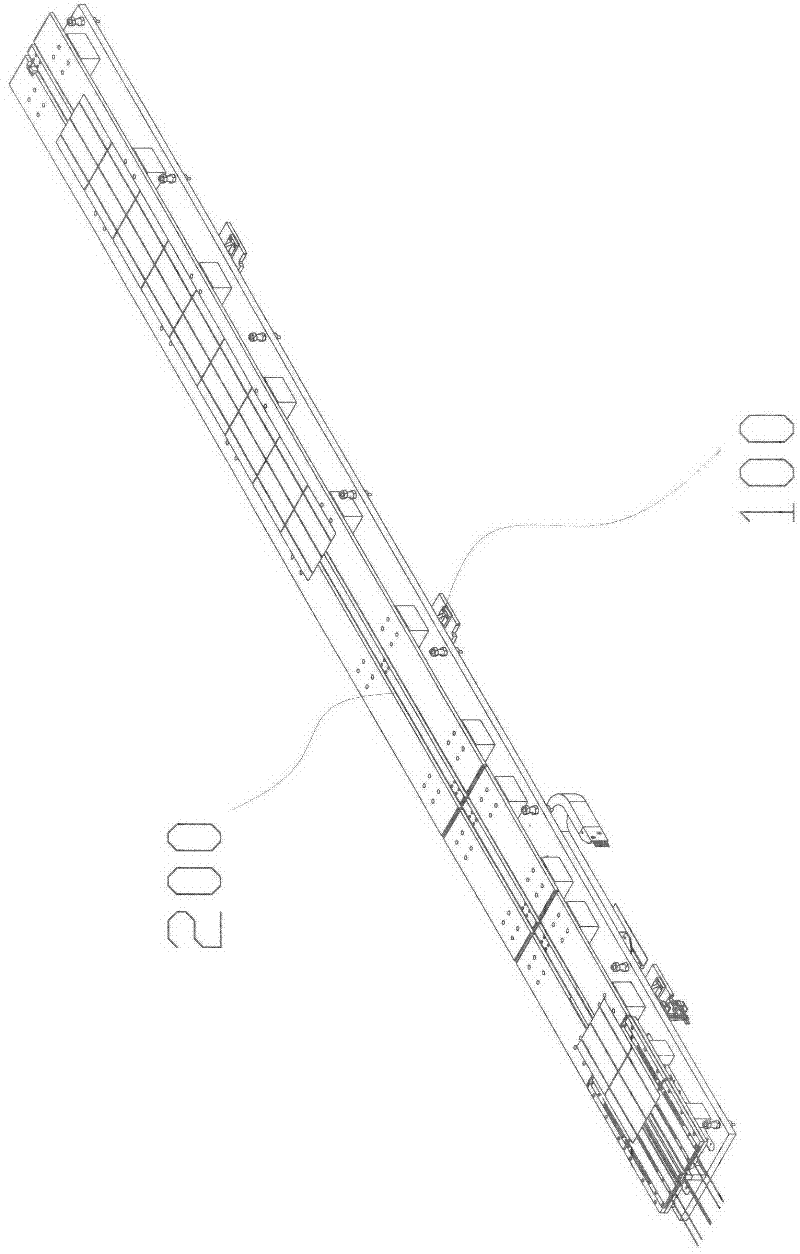

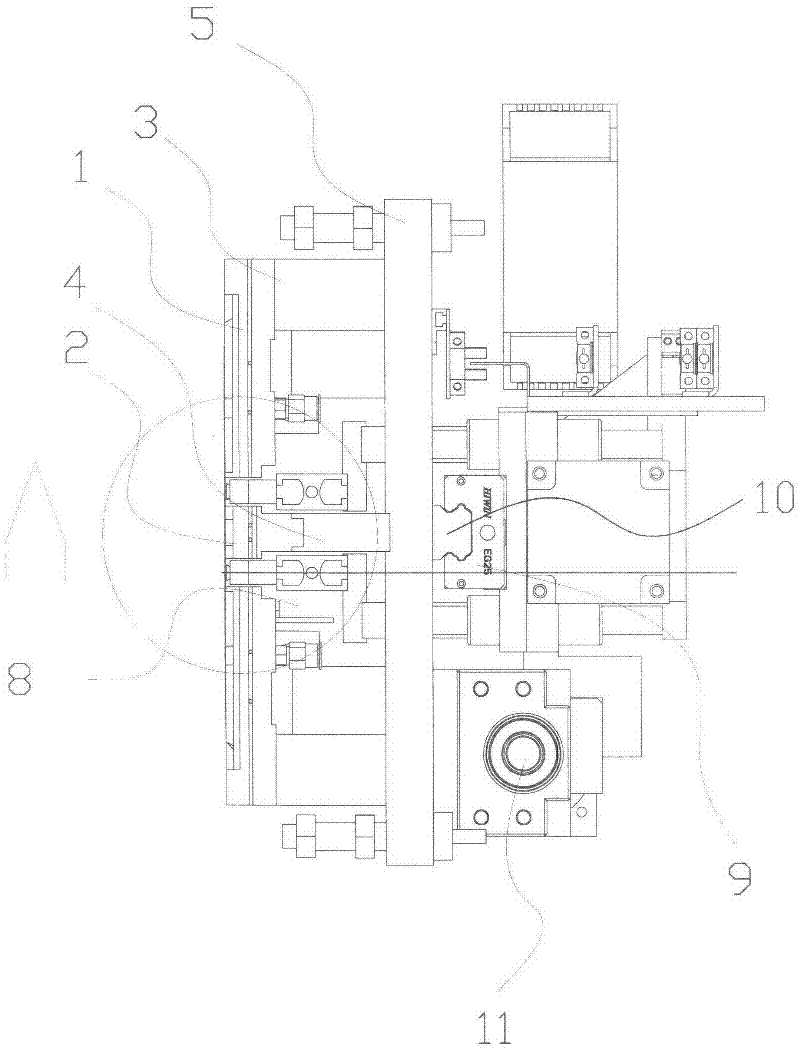

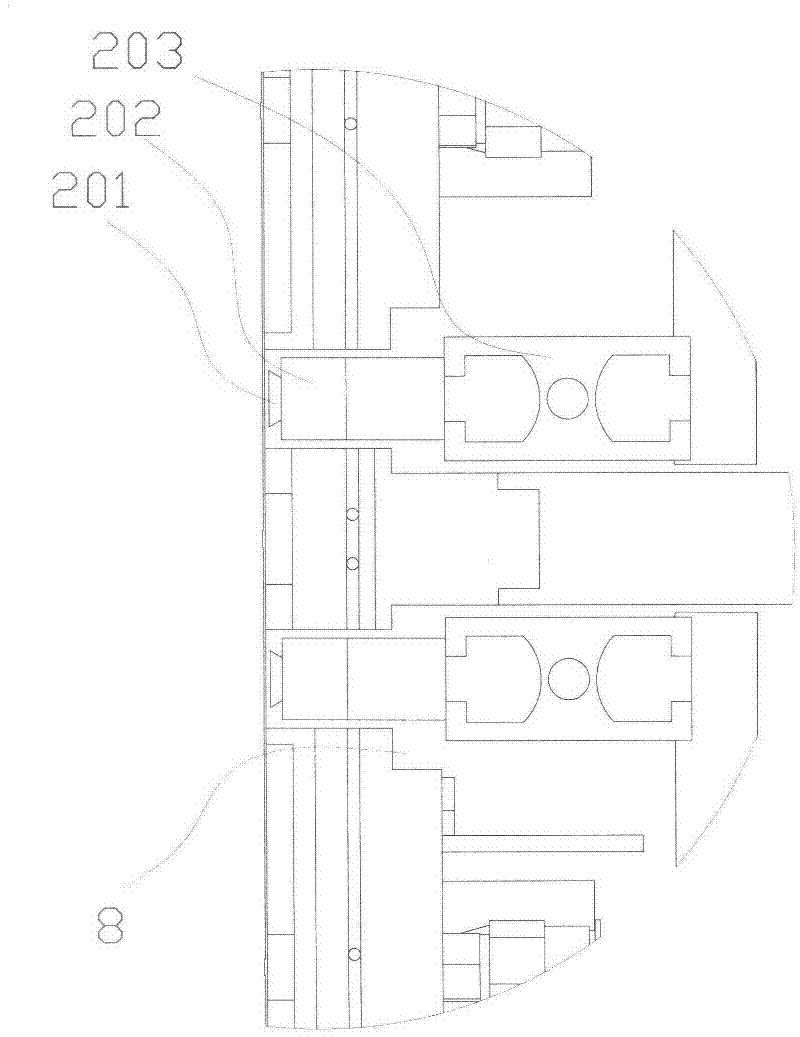

[0024] Such as Figure 1-7A conveying mechanism shown includes two first rails 1, a second rail 2, two first support seats 3, a second support seat 4, a fixed base plate 5, several lifting mechanisms 100, several vacuum adsorption devices 200, A horizontal transmission shaft 11, a horizontal fixed shaft 14, a first motor 13 and a second motor 12, the upper end of the lifting mechanism 100 passes through the fixed base plate 5, because it is very easy when the solar cells are unevenly pressed broken, causing losses, so it is necessary to increase the first support base 3 and the second support base 4 for supporting the first rail 1 and the second rail 2, and the first support base 3 is located in the lift Above the fixed bottom plate 5 on both sides of the mechanism 100, the second support base 4 is located above the fixed base plate 5 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com