Flange connector with dovetail groove structure

A connector and flange type technology, which is applied in the field of flange type connectors, can solve problems such as the sealing ring falling off, the sealing ring being difficult to set, and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

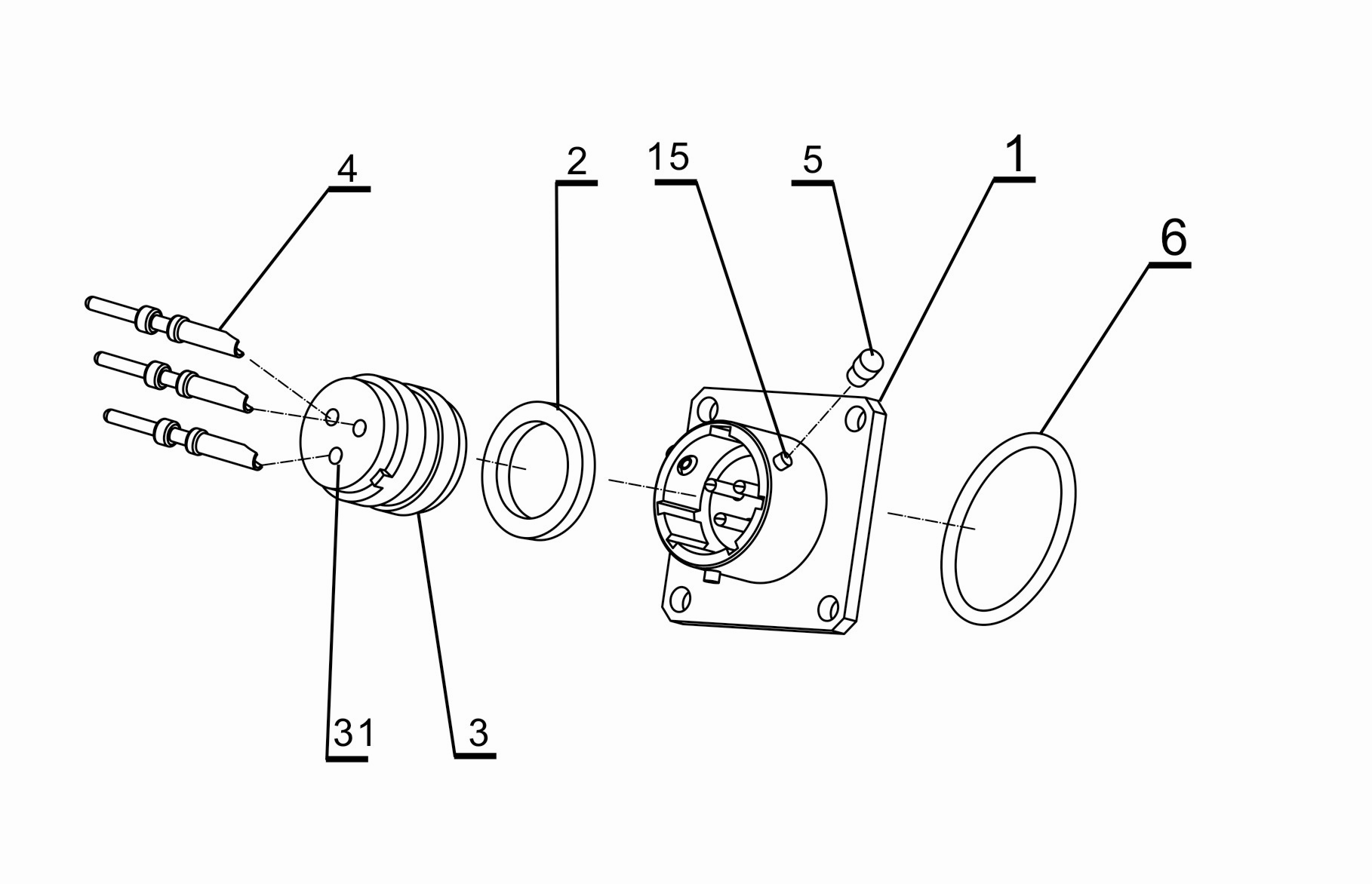

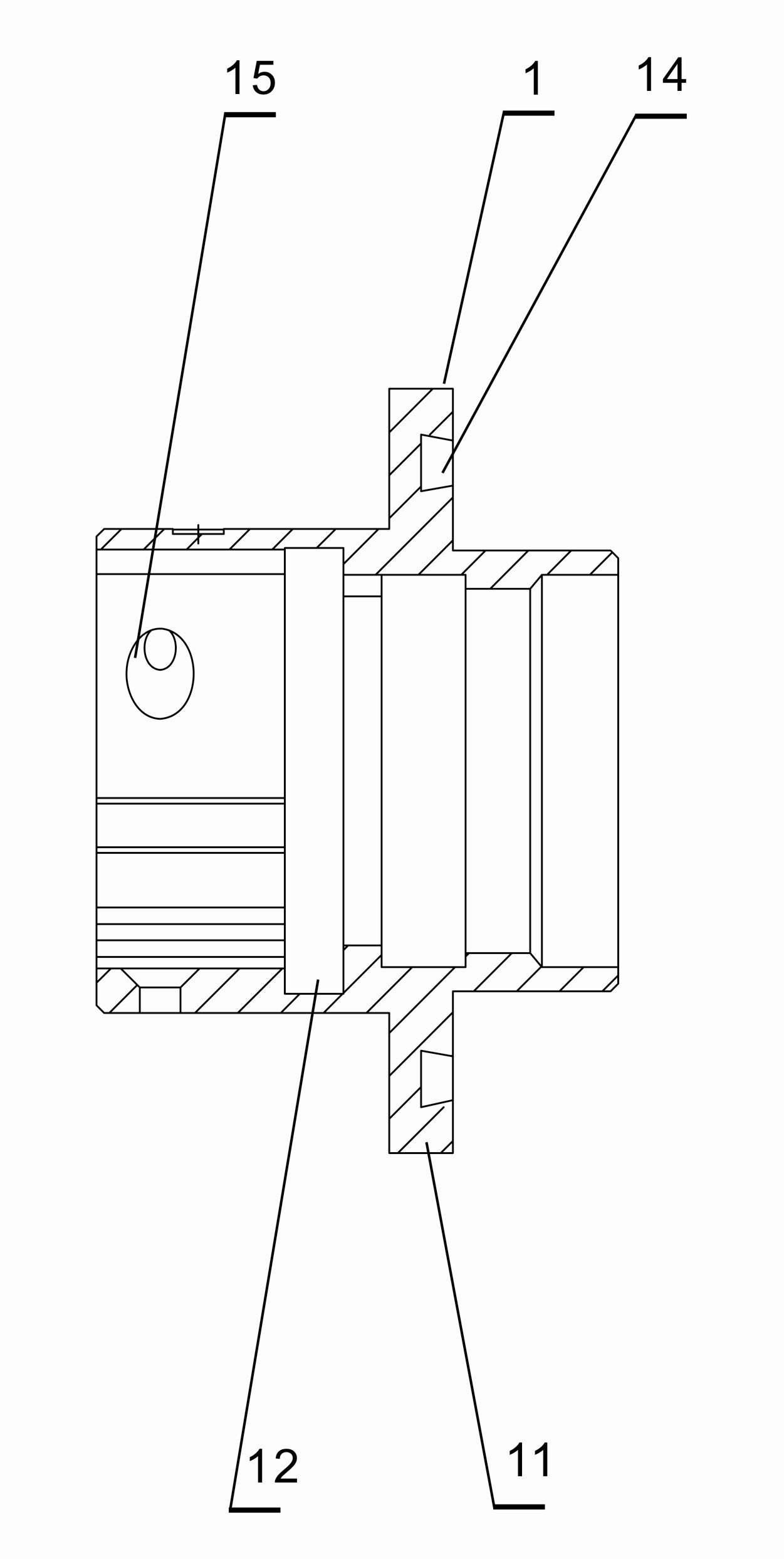

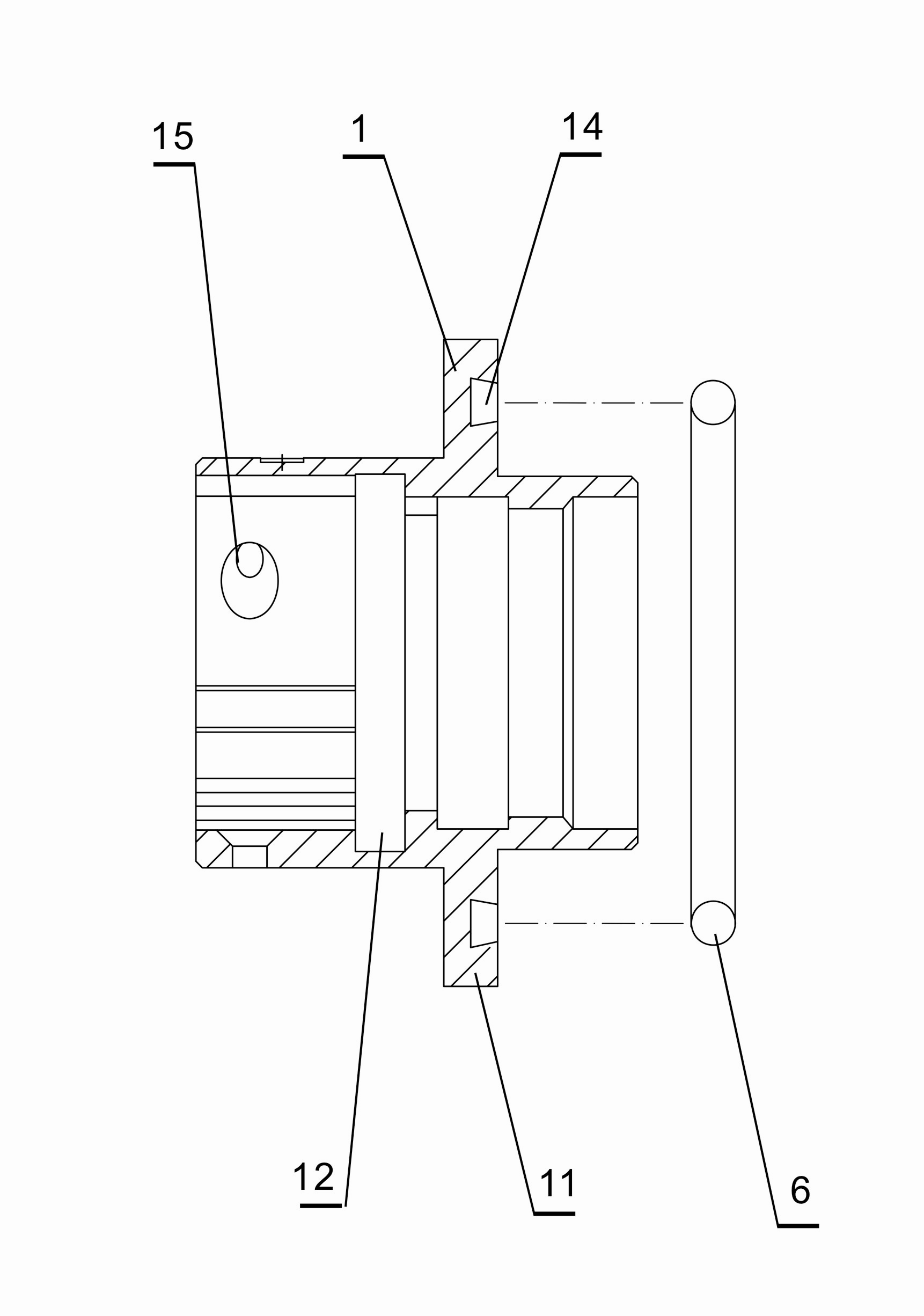

[0011] refer to figure 1 , figure 2 , image 3 , the present invention includes a connector base 1, a gasket 2, an insulator 3, a contact piece 4, a staple 5 and an "O" ring 6, the connector base 1 is a cylinder and the outer wall of the cylinder is provided with a A combination of square flanges 11, with sealing grooves 12 inside the cylinder, several screw holes 15 around the cylinder, mounting holes 13 on the four corners of the square flange 11, and ring grooves with dovetail-shaped cross-sections on the end surface 14. The insulator 3 is in the shape of a cylinder, and several contact holes 31 are arranged on it; the gasket 2 is arranged in the sealing groove 12 of the connector base 1, and the insulator 3 is arranged in the cylinder and connected with the gasket 2 touch, the contact piece 4 is set in the contact piece hole 31 of the insulator 3, the staple 5 is set in the screw hole 15 of the connector base 1 and clamped with the insulator 3, and the "O" ring 6 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com