Sub spray nozzle for variable spraying rotary spray head

A sub-nozzle, rotary technology, applied in the direction of spraying device, spraying device with movable outlet, etc., can solve the problem of uneven distribution of water, and achieve the effect of solving uneven distribution of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

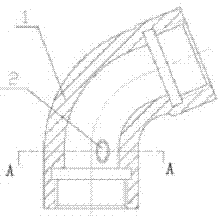

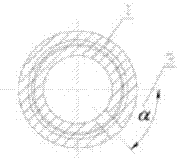

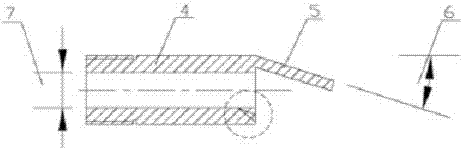

[0012] Such as figure 1 As shown: the turning point 1 of the nozzle pipe of the main nozzle has a secondary nozzle installation hole 2, and the included angle between the axial direction of the secondary nozzle installation hole 2 and the main jet flow direction of the main nozzle is figure 2 The sub-nozzle installed in Angle 3, assuming for the irrigation polygonal spraying area, the size of the secondary nozzle installation angle 3 is sprayed by the main nozzle The angle between the direction of the longest range and the direction of the shortest range is determined by the polygonal spraying area, and the value of the installation angle 3 of the secondary nozzle satisfy The sub-nozzle 4 with a circular cross-section is threaded or welded with the sub-nozzle mounting hole 2. When the pressure rises during the rotation of the main nozzle, the flow increases, and the sub-nozzle is in a high-pressure state like the main jet of the main nozzle. The spraying position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com