Spray head tilting mechanism

A technology of tilting mechanism and nozzle, which is applied in the field of water jet progressive forming, can solve the problems affecting forming efficiency and forming precision, and achieve high forming efficiency and forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

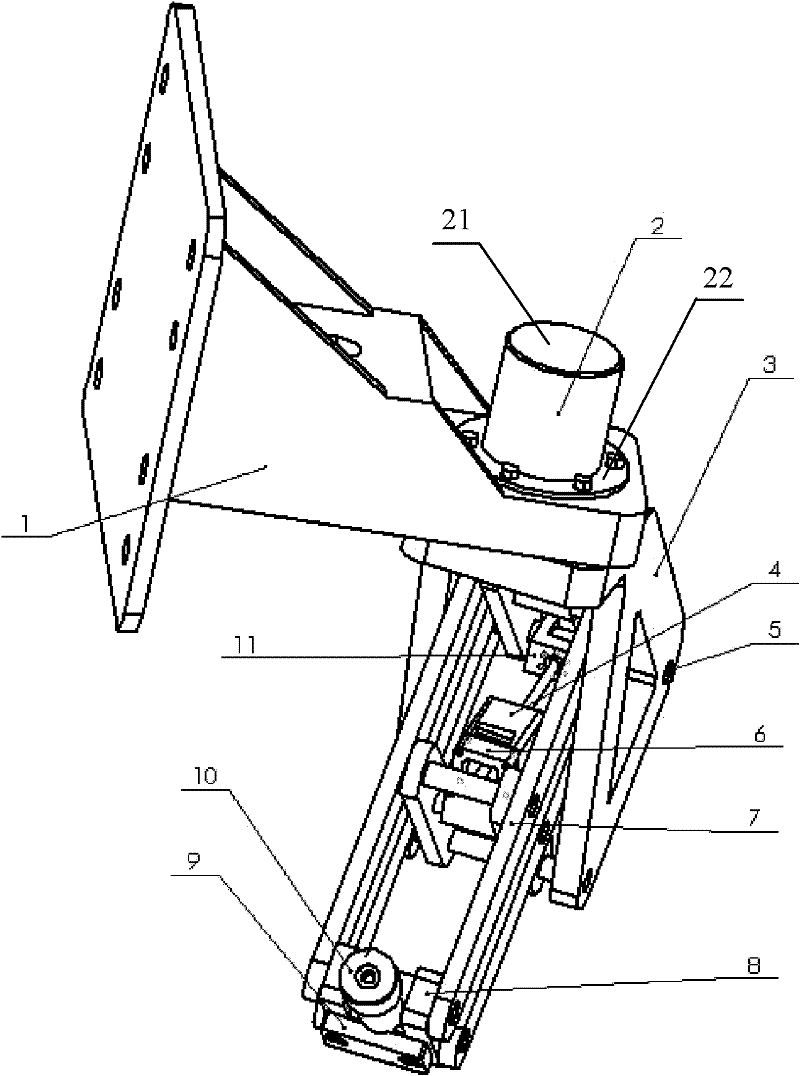

[0027] Please refer to Figure 5 , the specific implementation is as follows: first, the linear motor 4 drives the parallel rod hinge mechanism 7 to make the nozzle 10 tilt to the required angle value; after the angle is determined, the rotary drive motor 2 drives the turret 3 and the following connected mechanisms Rotate to adjust the direction of the inclination angle of the spray head 10, and after the inclination direction is determined, the inclination posture of the spray head 10 can be maintained. The next time you adjust the tilt posture, just follow the above steps to readjust.

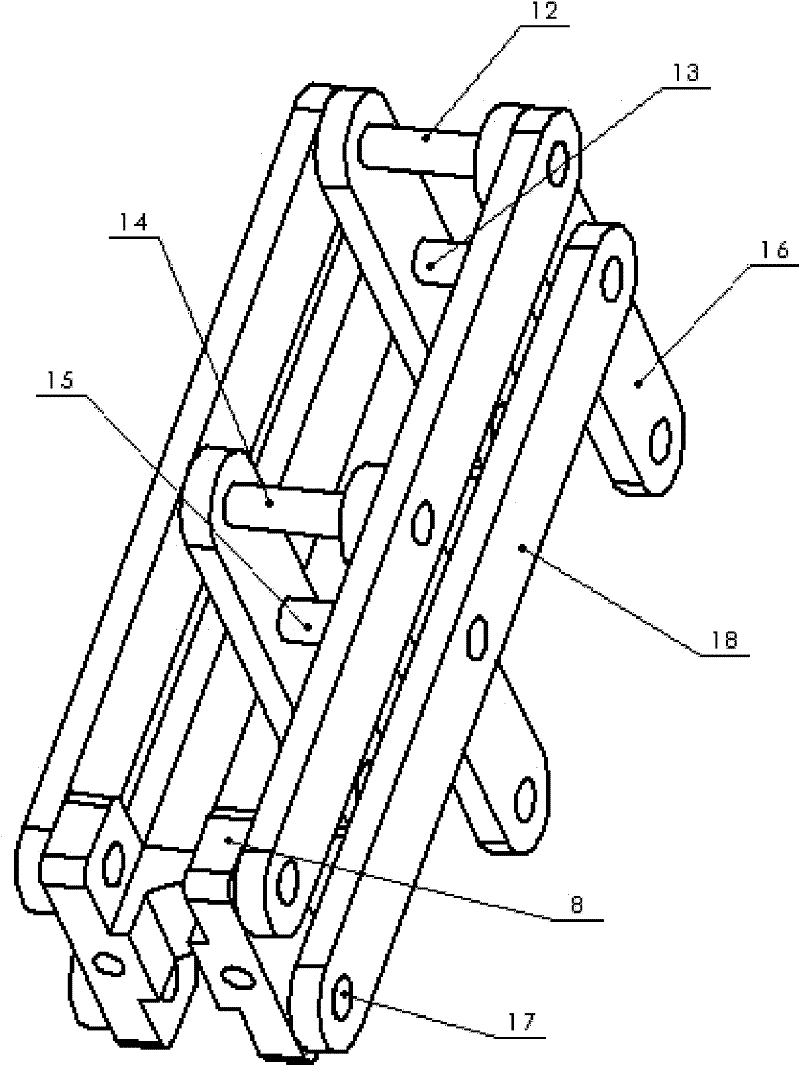

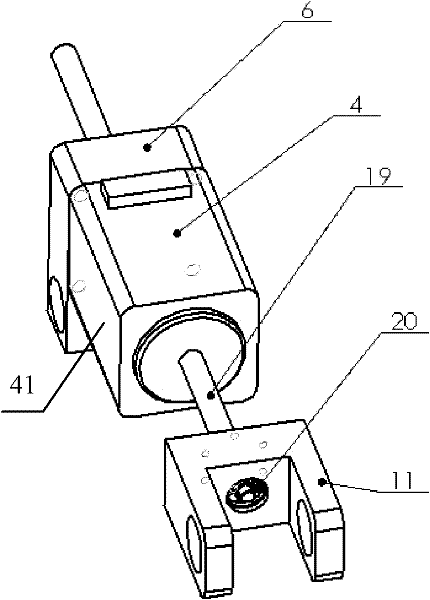

[0028] The rotary drive motor 2 is used to drive the rotation of the turret 3, so as to adjust the direction of the inclination angle of the nozzle 10; the linear motor 4 installed in the parallel rod hinge mechanism 7 is used to drive the parallel rod hinge mechanism 7 to realize the adjustment of the nozzle 10 The size of the inclination angle in a certain direction. In addition, the para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com