Installing device of separated type cosmetic cap body

A technology for installing devices and cosmetics, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as increasing production costs, wasting manpower and time, and increasing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further elaborated below by way of specific embodiments:

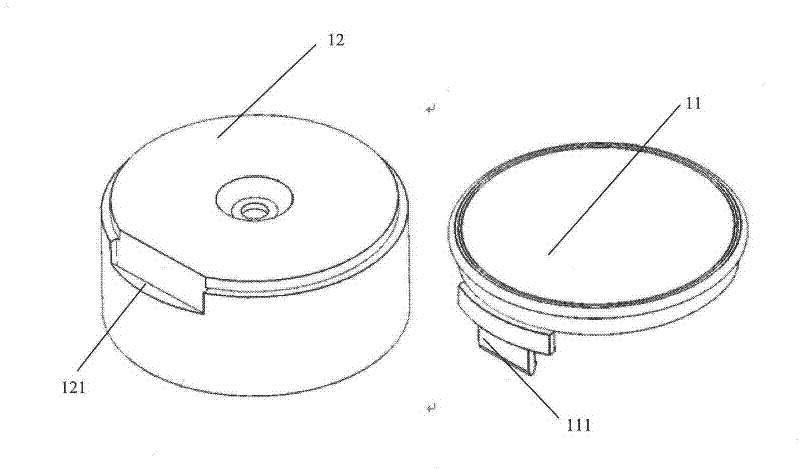

[0018] This embodiment provides a separate cosmetic cover installation device (such as figure 1 and figure 2 ), the detachable cosmetic cover 1 includes an upper cover 11 and a lower cover 12, the lower surface edge of the upper cover 12 also includes a downwardly protruding latch 121, and the upper surface edge of the lower cover 11 is concavely provided with A socket 111 that engages with the latch.

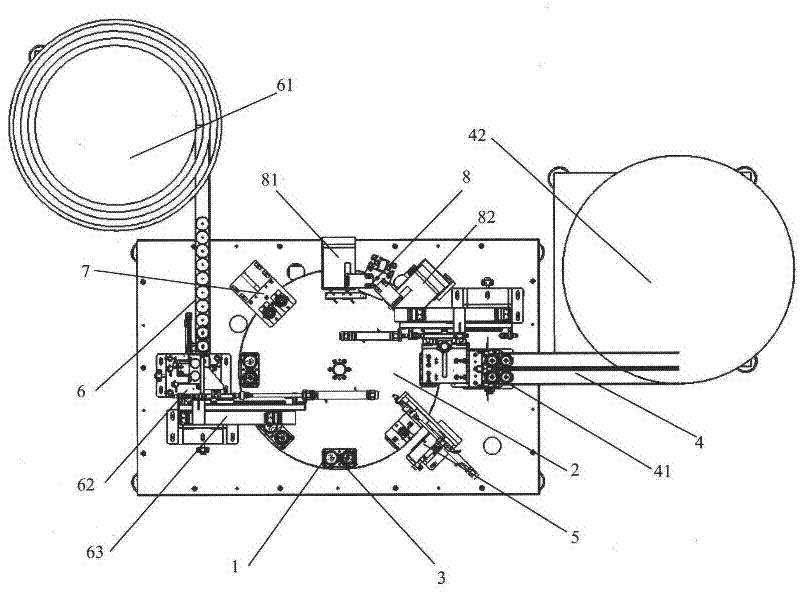

[0019] The installation device includes a controller, on which a turntable 2 is arranged, and several toolings 3 are arranged on the upper surface of the turntable, and a lower cover feeding device 4, an oiling device 5, and an upper cover body are sequentially arranged on the periphery of the turntable in a clockwise or counterclockwise direction. Cover feeding device 6 , pressing device 7 and discharging device 8 . The lower cover feeding device 4 includes a lower cover feeding vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com